This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

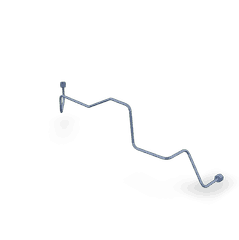

The Cummins 4970107 Pressure Sensing Tube is a component designed to facilitate the monitoring and regulation of pressure within the systems of commercial trucks. Its role is significant as it contributes to the overall efficiency and reliability of truck operations by ensuring that pressure levels are maintained within optimal ranges 1.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a conduit that allows for the transmission of pressure from one part of a system to a sensor or regulator. Within a vehicle’s system, it functions by connecting to various components where pressure needs to be measured or controlled. The principles of pressure sensing technology involve the detection of force per unit area exerted by a fluid, which is then converted into an electrical signal for processing by the vehicle’s electronic control unit 2.

Purpose and Role in Truck Operation

The 4970107 Pressure Sensing Tube plays a specific role in the operation of a truck by providing accurate pressure readings to the engine control module. It is integrated with other systems and components, such as the fuel injection system, to ensure that the engine operates under the correct pressure conditions. This integration is vital for the precise delivery of fuel and the overall performance of the engine 3.

Key Features

The 4970107 Pressure Sensing Tube is characterized by several key features. It is constructed from durable materials that can withstand the harsh conditions within a truck’s engine compartment. The design elements include a robust connection system that ensures a secure fit and reliable pressure transmission. Technological advancements in the tube’s construction may include enhanced resistance to corrosion and improved accuracy in pressure sensing 4.

Benefits

The benefits of the 4970107 Pressure Sensing Tube include improved performance of the truck’s engine due to accurate pressure readings, increased reliability through durable construction, and enhanced efficiency in fuel delivery and consumption. These factors contribute to the overall effectiveness of the truck’s operation 1.

Installation Process

Installing the 4970107 Pressure Sensing Tube requires a step-by-step approach to ensure proper function. The process involves identifying the correct location for the tube, using the appropriate tools to connect it to the system, and following safety precautions to prevent damage to the tube or surrounding components. Detailed instructions should be followed to achieve a secure and effective installation 2.

Troubleshooting Common Issues

Common problems with pressure sensing tubes can include leaks, inaccurate readings, or physical damage. Diagnosing these issues involves checking the tube for signs of wear or damage, testing the pressure readings against known values, and inspecting the connections for tightness and integrity. Recommended solutions may include replacing damaged sections, recalibrating the sensor, or tightening connections 3.

Maintenance Tips

To ensure the longevity and optimal performance of the 4970107 Pressure Sensing Tube, regular maintenance is advised. This includes periodic checks for signs of wear or damage, cleaning the tube and connections to remove any buildup that could affect pressure readings, and ensuring that all connections remain tight and secure 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a diverse product range, Cummins is committed to providing reliable and efficient solutions for the automotive industry, including components like the 4970107 Pressure Sensing Tube.

Pressure Sensing Tube 4970107 in Cummins Engines

The Pressure Sensing Tube 4970107 is a critical component in several Cummins engine models, ensuring accurate monitoring and regulation of pressure within the engine system. This part is integral to maintaining optimal engine performance and efficiency.

QSK19 and CM850 Engines

In the QSK19 and CM850 engines, the Pressure Sensing Tube 4970107 plays a pivotal role in the engine’s fuel injection system. It is responsible for accurately measuring the pressure within the fuel system, which is essential for the engine control unit (ECU) to adjust fuel delivery and timing. This ensures that the engine operates smoothly and efficiently, regardless of the load or operating conditions.

MCRS Engines

The MCRS engines also utilize the Pressure Sensing Tube 4970107, where it is integrated into the engine’s exhaust gas recirculation (EGR) system. This part helps in detecting the pressure within the EGR system, which is crucial for the ECU to manage the recirculation of exhaust gases. This process helps in reducing nitrogen oxide (NOx) emissions and improving fuel economy.

Common Functionality

Across these engines, the Pressure Sensing Tube 4970107 is designed to withstand high temperatures and pressures, ensuring durability and reliability. Its precise measurements are vital for the ECU to make real-time adjustments, enhancing overall engine performance and longevity.

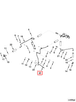

Role of Part 4970107 Pressure Sensing Tube in Engine Systems

The Part 4970107 Pressure Sensing Tube is an integral component in the efficient operation of various engine systems. It is specifically designed to interface with the plumbing and oil replenishing system, ensuring optimal performance and reliability.

Integration with Plumbing

In the context of engine plumbing, the Pressure Sensing Tube is responsible for monitoring and regulating the pressure within the system. It is connected to key points in the plumbing network, allowing it to detect any fluctuations in pressure. This data is then used to make necessary adjustments, ensuring that the flow of fluids remains consistent and within safe parameters. The tube’s precise measurements help in preventing issues such as leaks or blockages, which could otherwise lead to engine malfunction.

Function in the Oil Replenishing System

Within the oil replenishing system, the Pressure Sensing Tube plays a significant role in maintaining the correct oil levels and pressure. It is strategically placed to sense the pressure of the oil as it circulates through the system. This information is vital for the system to determine when additional oil is needed. The tube ensures that the oil pressure remains stable, which is essential for the lubrication of moving parts and the overall health of the engine. By providing accurate pressure readings, it helps in timely replenishment, thereby extending the lifespan of the engine components and enhancing performance.

Conclusion

The Cummins 4970107 Pressure Sensing Tube is a vital component in the operation and maintenance of commercial truck engines. Its accurate pressure readings contribute to the efficiency, reliability, and performance of the engine. Regular maintenance and proper installation are essential to ensure the longevity and effectiveness of this Cummins part.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ ↩ -

Halderman, James D. Automotive Principles: Diagnosis and Service. Prentice Hall, 2012.

↩ ↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ ↩ -

Han, Zhiyu. Simulation and Optimization of Internal Combustion Engines. SAE International, 2022.

↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.