This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

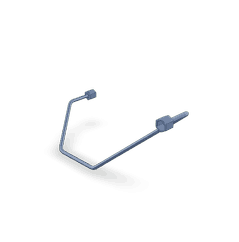

The Cummins 4970108 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the engine management system, contributing to the overall performance and efficiency of the vehicle. Understanding its purpose and significance is key to maintaining and optimizing truck operations.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used in automotive systems to monitor and transmit pressure data from various parts of the engine to the management system. These tubes facilitate the accurate measurement of pressure, which is crucial for the proper functioning of the engine. They are typically made from durable materials to withstand the harsh conditions within an engine environment 1.

Purpose of the 4970108 Pressure Sensing Tube

The Cummins 4970108 Pressure Sensing Tube plays a role in the engine management system by providing precise pressure readings. This data is used by the engine control unit (ECU) to make adjustments to fuel injection, timing, and other parameters, ensuring optimal engine performance. Its integration within the system allows for real-time monitoring and adjustment, contributing to efficient operation 2.

Key Features

The 4970108 Pressure Sensing Tube is characterized by its robust design and the quality materials used in its construction. These features enhance its performance and durability, allowing it to operate effectively under various conditions. The tube’s design ensures accurate pressure readings, which are vital for the engine management system’s functionality.

Benefits

The use of the 4970108 Pressure Sensing Tube offers several advantages. It contributes to improved engine performance by enabling the ECU to make precise adjustments based on accurate pressure data. This can lead to enhanced fuel efficiency and reliable operation, even under demanding conditions. The tube’s durability ensures long-term performance, reducing the need for frequent replacements.

Installation and Integration

Installing the 4970108 Pressure Sensing Tube requires careful attention to ensure proper integration within the engine management system. The process involves connecting the tube to the appropriate sensors and ensuring it is securely fitted. Tools and precautions specific to the installation should be observed to avoid damage to the component or the system.

Troubleshooting and Maintenance

Common issues with the 4970108 Pressure Sensing Tube may include inaccurate readings or physical damage. Diagnostic procedures should be followed to identify the problem, which may involve checking connections, inspecting the tube for damage, or calibrating the sensor. Regular maintenance, such as cleaning and inspecting the tube, can help prevent issues and ensure optimal performance.

Safety Considerations

When working with the 4970108 Pressure Sensing Tube, it is important to observe safety practices. This includes ensuring the engine is off and cool before beginning any work, using appropriate tools and equipment, and following manufacturer guidelines for installation and maintenance. These precautions help protect both the technician and the vehicle.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history of innovation and commitment to quality, Cummins serves various industries, including commercial trucking. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding requirements of modern transportation.

Role of Part 4970108 Pressure Sensing Tube in Engine Systems

The 4970108 Pressure Sensing Tube is integral to the efficient operation of various engine systems, particularly in the context of plumbing and the Oil Replenishing System (ORS).

In the plumbing system of an engine, the Pressure Sensing Tube is employed to monitor and regulate the pressure within the fluid lines. This ensures that the fluid dynamics are maintained within optimal parameters, preventing issues such as leaks or component failure due to excessive pressure. The tube interfaces with pressure sensors, which relay data to the engine control unit (ECU), allowing for real-time adjustments and ensuring the system operates smoothly.

Within the Oil Replenishing System (ORS), the Pressure Sensing Tube plays a significant role in maintaining the correct oil pressure. The ORS is designed to automatically replenish oil levels within the engine, ensuring lubrication is consistent and adequate. The Pressure Sensing Tube provides feedback on the oil pressure, allowing the system to adjust the flow rate of oil being replenished. This helps in maintaining the engine’s performance and longevity by ensuring that all moving parts are properly lubricated under varying operational conditions.

Conclusion

Overall, the 4970108 Pressure Sensing Tube is a key component in these systems, facilitating precise pressure monitoring and control, which is essential for the reliable and efficient operation of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.