4975874

Pressure Sensing Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 4975874 Pressure Sensing Tube is a component designed to monitor and relay pressure data within the systems of commercial trucks. Its purpose is to ensure that the truck’s engine and other critical systems operate within optimal pressure parameters. This part contributes to the overall efficiency and reliability of the vehicle by providing accurate pressure readings that help in the management and control of various engine functions 1.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used in automotive systems to measure and transmit pressure data from one point to another. These tubes are integral to the feedback mechanisms that allow for the precise control of engine and system operations. They function by connecting to pressure sensors or gauges, which then convert the physical pressure into an electrical signal that can be interpreted by the vehicle’s electronic control unit (ECU). This data is crucial for maintaining system integrity and performance 2.

Purpose and Role in Truck Operation

The Cummins 4975874 Pressure Sensing Tube plays a specific role in the operation of a truck by facilitating the accurate measurement of pressure within the engine’s systems. It is integrated with the truck’s electronic control systems, allowing for real-time monitoring and adjustment of engine parameters based on the pressure data it provides. This integration ensures that the engine operates efficiently and within safe limits, contributing to the overall performance and longevity of the truck 3.

Key Features

The Cummins 4975874 Pressure Sensing Tube is characterized by several key features that enhance its performance. It is constructed from durable materials that can withstand the high pressures and temperatures found within a truck’s engine compartment. The design of the tube includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature unique characteristics such as reinforced sections or specialized coatings to improve its durability and resistance to wear 4.

Benefits

The Cummins 4975874 Pressure Sensing Tube offers several benefits that contribute to the efficiency and reliability of a truck’s engine system. By providing accurate pressure readings, it allows for better control and management of engine functions, leading to improved performance and fuel efficiency. The tube’s durable construction and precise design also contribute to its reliability, reducing the likelihood of failures or leaks that could compromise engine operation 5.

Installation and Integration

Proper installation and integration of the Cummins 4975874 Pressure Sensing Tube are crucial for ensuring its effective operation within a truck’s system. Installation guidelines typically include verifying that all connections are secure and leak-free, and that the tube is correctly positioned within the engine compartment. It is also important to ensure that the tube is compatible with the truck’s existing systems and that all electronic connections are properly made to allow for accurate data transmission to the ECU 6.

Troubleshooting and Maintenance

To maintain the Cummins 4975874 Pressure Sensing Tube’s performance, regular maintenance and troubleshooting are recommended. Common issues may include leaks at connection points or blockages within the tube, which can affect the accuracy of pressure readings. Maintenance tips include periodic inspection of the tube and connections for signs of wear or damage, and ensuring that all fittings remain tight and secure. Following best practices for maintenance can help ensure the longevity and optimal performance of the pressure sensing tube 7.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company offers a wide range of products designed to meet the demanding requirements of commercial vehicles, including engines, powertrain components, and aftermarket parts. Cummins’ commitment to excellence and customer satisfaction has made it a trusted name in the industry 8.

Pressure Sensing Tube 4975874 in Cummins Engines

The Pressure Sensing Tube 4975874, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s operation, ensuring accurate pressure readings that are essential for maintaining optimal performance and efficiency.

ISM CM876 Engines

In the ISM CM876 engines, the Pressure Sensing Tube 4975874 plays a pivotal role in the engine’s fuel injection system. It is designed to measure the pressure within the fuel system, providing vital data to the engine control unit (ECU). This information is crucial for the ECU to adjust fuel delivery, ensuring the engine operates within its designed parameters 9.

QSM11 CM876 Engines

Similarly, in the QSM11 CM876 engines, the Pressure Sensing Tube 4975874 is used to monitor fuel system pressure. The accuracy of the pressure readings is essential for the engine’s performance, particularly in maintaining the correct air-fuel ratio. This ensures that the engine runs efficiently and reduces emissions 10.

Common Application

Both the ISM CM876 and QSM11 CM876 engines utilize the Pressure Sensing Tube 4975874 in their fuel systems. The commonality in their application underscores the importance of this component in ensuring the engines’ reliability and performance. The tube’s design and placement are critical to capturing accurate pressure readings, which are then used by the engine’s control systems to make necessary adjustments 11.

Installation and Maintenance

Proper installation of the Pressure Sensing Tube 4975874 is crucial to ensure it functions correctly. Regular maintenance checks should be performed to verify that the tube is free from obstructions and is securely connected. Any damage or wear to the tube can lead to inaccurate pressure readings, potentially causing engine performance issues 12.

Compatibility

The Pressure Sensing Tube 4975874 is specifically designed to fit the ISM CM876 and QSM11 CM876 engines. It is essential to use the correct part number when sourcing replacements to ensure compatibility and maintain the engine’s performance standards 13.

Role of Part 4975874 Pressure Sensing Tube in Engine Systems

The Part 4975874 Pressure Sensing Tube is integral to the efficient operation of several engine systems, particularly in the context of recirculation and exhaust management.

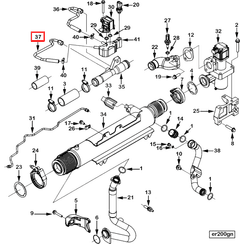

Integration with Exhaust Systems

In exhaust systems, the Pressure Sensing Tube is employed to monitor the backpressure within the exhaust manifold. This data is vital for the Engine Control Unit (ECU) to adjust fuel delivery and ignition timing, ensuring optimal performance and emissions control. The tube is typically connected to a pressure sensor, which relays real-time data to the ECU. This allows for dynamic adjustments that enhance engine efficiency and reduce harmful emissions 14.

Function in Recirculation Systems

For recirculation systems, such as Exhaust Gas Recirculation (EGR), the Pressure Sensing Tube plays a significant role in maintaining the correct flow of exhaust gases back into the intake manifold. By measuring the pressure differential, the tube helps the ECU determine the appropriate amount of recirculated exhaust gas. This not only improves fuel economy but also reduces nitrogen oxides (NOx) emissions, contributing to a cleaner combustion process 15.

Synergy with Other Components

The Pressure Sensing Tube works in concert with various other components to ensure seamless engine operation. For instance, it interfaces with the EGR valve, turbocharger (if present), and the intake manifold. The data collected by the tube aids in the precise control of these components, leading to enhanced engine performance and durability 16.

Conclusion

In summary, the Part 4975874 Pressure Sensing Tube is a key element in modern engine management systems, providing essential data that enables the ECU to make informed decisions regarding fuel delivery, ignition timing, and recirculation rates. Its role in ensuring the efficient and reliable operation of commercial truck engines cannot be overstated.

-

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4310737, ISX15 CM2250 SN.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Company Overview. Available at: Cummins Official Website.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4310737, ISX15 CM2250 SN.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 4310737, ISX15 CM2250 SN.

↩ -

Hilgers, Michael. The Diesel Engine Second Edition. Springer Nature, 2023.

↩ -

Klyde, Michael, and Kirk VanGelder. Advanced Automotive Electricity and Electronics. Jones Bartlett Learning, 2010.

↩ -

Calder, Nigel. Diesel Engine Care and Repair. The McGraw-Hill Companies, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.