This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

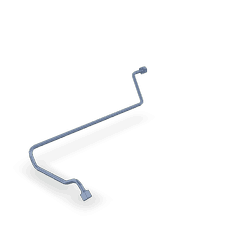

The Cummins 4978325 Pressure Sensing Tube is a component designed to monitor and regulate pressure within the engine management system of commercial trucks. Its role is significant in ensuring the efficient and reliable operation of these vehicles.

Basic Concepts of Pressure Sensing Tubes

A pressure sensing tube is a component used to measure and convey pressure data from one part of a system to another. It functions by transmitting pressure changes to a sensor or gauge, which then provides feedback to the system’s control unit. This feedback loop allows for the monitoring and regulation of pressure, ensuring that the system operates within specified parameters 1.

Purpose of the Cummins 4978325 Pressure Sensing Tube

The Cummins 4978325 Pressure Sensing Tube plays a specific role in the operation of commercial trucks by providing accurate pressure readings to the engine management system. This allows for precise control of various engine functions, contributing to overall performance and efficiency.

Key Features

The Cummins 4978325 Pressure Sensing Tube is characterized by its robust design and the use of high-quality materials. These features ensure durability and reliable performance under the demanding conditions typical of commercial truck operations. The tube’s design also includes features that enhance its accuracy and responsiveness to pressure changes.

Benefits

Using the Cummins 4978325 Pressure Sensing Tube can lead to improved engine performance, enhanced fuel efficiency, and increased reliability. These benefits are achieved through the precise monitoring and regulation of engine pressure, which allows for optimal engine operation 2.

Installation and Integration

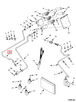

Proper installation and integration of the Cummins 4978325 Pressure Sensing Tube within a commercial truck’s engine system are crucial for its effective operation. This process involves following manufacturer guidelines to ensure the tube is correctly positioned and connected, allowing for accurate pressure readings and system feedback.

Troubleshooting and Maintenance

Common issues related to the Cummins 4978325 Pressure Sensing Tube can often be addressed through regular maintenance practices. These include checking for leaks, ensuring connections are secure, and verifying the tube’s alignment within the system. Regular inspections can help identify potential problems before they lead to more significant issues.

Safety Considerations

When working with the Cummins 4978325 Pressure Sensing Tube, it is important to follow proper handling procedures and take precautions to prevent accidents or injuries. This includes wearing appropriate personal protective equipment and ensuring the engine is off and cool before beginning any work.

Environmental Impact

The production, use, and disposal of the Cummins 4978325 Pressure Sensing Tube have environmental implications. Efforts to minimize its ecological footprint include using recyclable materials in its construction and ensuring that disposal methods are environmentally friendly.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a commitment to innovation and sustainability, Cummins serves commercial truck markets with a wide range of products designed to enhance performance, efficiency, and reliability.

Pressure Sensing Tube 4978325 in Cummins Engines

The Pressure Sensing Tube 4978325 is a critical component in several Cummins engine models, ensuring accurate pressure readings for optimal engine performance. This part is integral to the engine’s operation, providing essential data for the engine control unit (ECU) to manage various functions.

QSK60 and CM850 Engines

In the QSK60 and CM850 engines, the Pressure Sensing Tube 4978325 is designed to monitor the pressure within the engine’s fuel system. This data is vital for maintaining the correct fuel injection timing and pressure, which directly impacts engine efficiency and power output. The tube’s placement and design ensure it can withstand the high pressures and temperatures typical of these heavy-duty engines.

MCRS Engines

The MCRS engines also utilize the Pressure Sensing Tube 4978325, integrating it into their sophisticated fuel management systems. This part plays a crucial role in the MCRS engines’ ability to deliver consistent performance across various operating conditions. The tube’s precision in measuring pressure helps maintain the delicate balance required for efficient fuel combustion, contributing to the engine’s overall reliability and durability.

Grouping of Engines

The Pressure Sensing Tube 4978325 is a shared component across the QSK60, CM850, and MCRS engines, highlighting its importance in Cummins’ engine lineup. This commonality underscores the engineering consistency and quality that Cummins maintains across its engine models, ensuring that each part performs reliably and effectively within its designated engine.

Role of Part 4978325 Pressure Sensing Tube in Engine Systems

The Part 4978325 Pressure Sensing Tube is integral to the operation of both the system and engine monitoring components. In the system, this tube facilitates the accurate measurement of pressure variations, which is essential for maintaining optimal performance and efficiency. It connects to various sensors within the system, allowing for real-time data collection on pressure changes. This data is then used to make necessary adjustments to the system’s operation, ensuring that it functions within the desired parameters.

In the context of engine monitoring, the Pressure Sensing Tube plays a significant role in providing precise pressure readings from different parts of the engine. These readings are vital for monitoring the health and performance of the engine. The tube is typically connected to pressure sensors located in critical areas such as the intake manifold, fuel system, and exhaust. By delivering consistent and accurate pressure data, it enables the engine monitoring system to detect anomalies, prevent potential failures, and ensure that the engine operates efficiently.

The integration of the Pressure Sensing Tube with these components underscores its importance in both maintaining system integrity and enhancing engine performance through meticulous monitoring and data-driven adjustments.

Conclusion

The Cummins 4978325 Pressure Sensing Tube is a vital component in the engine management systems of commercial trucks, ensuring accurate pressure readings and contributing to the overall performance and efficiency of the engine. Its robust design, high-quality materials, and precise functionality make it an essential part of Cummins’ engine lineup, particularly in the QSK60, CM850, and MCRS engines. Proper installation, regular maintenance, and adherence to safety protocols are crucial for maximizing the benefits of this part, while environmental considerations highlight the importance of sustainable practices in its production and disposal.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.