This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

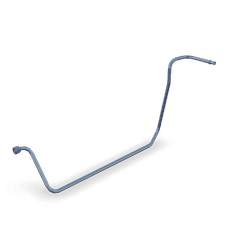

The Compressor Water Outlet Tube, identified by part number 4981016, is a component manufactured by Cummins, a well-established name in the automotive industry. This tube is integral to the cooling systems of heavy-duty truck engines, ensuring efficient operation and longevity of the engine.

Basic Concepts and Functionality

The Compressor Water Outlet Tube operates on fundamental principles of fluid dynamics within the engine’s cooling system. Its primary role is to facilitate the movement of coolant from the compressor to other parts of the engine, ensuring that heat is effectively managed. By directing the flow of coolant, it helps maintain optimal engine temperature, which is vital for the engine’s performance and durability 1.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the 4981016 Compressor Water Outlet Tube serves a specific purpose. It is designed to enhance the efficiency of the cooling system by ensuring a consistent and reliable flow of coolant. This contributes to the overall performance and efficiency of the engine, allowing it to operate under demanding conditions without overheating 2.

Key Features

The 4981016 Compressor Water Outlet Tube is characterized by several key features that enhance its functionality. These include a robust material composition that ensures durability, a design tailored to fit seamlessly within the engine’s cooling system, and unique characteristics that improve coolant flow and efficiency. These features collectively contribute to the tube’s reliability and effectiveness in heavy-duty applications 3.

Benefits

The advantages of the 4981016 Compressor Water Outlet Tube are manifold. It offers improved engine cooling efficiency, which is crucial for maintaining engine performance under various operating conditions. Its durable construction ensures reliability, even in the face of demanding environments. Furthermore, its design contributes to the overall efficiency and reliability of the engine cooling system 4.

Installation and Integration

Proper installation and integration of the Compressor Water Outlet Tube within the engine cooling system are paramount. Best practices include ensuring a secure fit, verifying the integrity of connections, and following manufacturer guidelines to avoid potential challenges. Careful attention to these details during installation can prevent issues and ensure optimal performance.

Troubleshooting and Maintenance

Identifying common issues related to the Compressor Water Outlet Tube involves monitoring for signs of leaks, blockages, or inefficient coolant flow. Diagnostic procedures may include visual inspections and pressure tests. Regular maintenance practices, such as cleaning and inspecting the tube for wear, can help ensure its optimal performance and longevity.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a rich history and a diverse product portfolio, Cummins is renowned for its quality and innovation in the automotive industry, particularly in the realm of heavy-duty truck components. The company’s commitment to excellence and customer satisfaction has established it as a trusted name in the industry.

Role of Part 4981016 Compressor Water Outlet Tube in Engine Systems

The 4981016 Compressor Water Outlet Tube is a critical component in the arrangement of engine systems, specifically within the compressor coolant circuit. This tube facilitates the efficient transfer of coolant from the compressor to other parts of the engine system, ensuring optimal thermal management.

In the compressor coolant arrangement, the 4981016 tube connects the outlet of the compressor to the inlet of the coolant system. This connection allows for the circulation of coolant, which absorbs heat generated by the compressor during operation. The coolant then carries this heat away, preventing overheating and maintaining the compressor’s efficiency and longevity.

The tube’s design ensures a secure and leak-free connection, which is vital for maintaining the integrity of the coolant system. It works in conjunction with other components such as the coolant pump, heat exchanger, and various hoses and fittings to create a cohesive coolant circulation system.

Effective thermal management is achieved as the coolant, after absorbing heat from the compressor, is typically routed to a heat exchanger where it releases the heat to the surrounding environment before returning to the compressor. This continuous cycle helps in stabilizing the operating temperature of the compressor, enhancing its performance and reliability.

Conclusion

In summary, the 4981016 Compressor Water Outlet Tube plays a significant role in the compressor coolant arrangement by ensuring efficient heat transfer and maintaining the overall thermal balance of the engine system. Its robust design, coupled with the manufacturer’s reputation for quality and innovation, makes it a reliable component for heavy-duty truck engines.

-

Shashank Arora, Alireza Tashakori Abkenar, and Shantha Gamini Jayasi, Heavyduty Electric Vehicles: From Concept to Reality, Elsevier, 2021.

↩ -

Michael Hilgers, The Drivers Cab, Springer Vieweg, 2022.

↩ -

R Mananathan, Automobile Wheel Alignment and Wheel Balancing, SAE International, 2022.

↩ -

Rajesh Rajamani, Vehicle Dynamics and Control, Springer, 2005.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.