This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 4998830 Pressure Sensing Tube is a critical component designed to monitor and regulate pressure within the systems of commercial trucks. Its role is significant in ensuring the efficient and safe operation of these vehicles. By providing accurate pressure readings, it helps maintain optimal performance and reliability in truck operations 1.

Basic Concepts of Pressure Sensing Tubes

A Pressure Sensing Tube is a device used to measure and transmit pressure data from one part of a system to another. It functions by connecting to a pressure source and transferring the pressure to a sensor or gauge, which then provides a reading. This component is integral to monitoring and regulating pressure, ensuring that systems operate within safe and efficient parameters 2.

Purpose of the 4998830 Pressure Sensing Tube

The 4998830 Pressure Sensing Tube plays a specific role in the operation of a truck by accurately measuring pressure in various systems. It is integrated with other components to ensure that pressure levels are maintained at optimal levels, contributing to the overall efficiency and safety of the vehicle. This tube works in conjunction with sensors and control units to provide real-time data, allowing for adjustments to be made as needed 3.

Key Features

The 4998830 Pressure Sensing Tube is characterized by several key features that enhance its performance. It is constructed from durable materials to withstand the harsh conditions of commercial truck environments. The design includes precise fittings and connections to ensure accurate pressure transmission. Additionally, it may feature unique elements such as reinforced sections or specialized coatings to improve durability and resistance to wear.

Benefits

The use of the 4998830 Pressure Sensing Tube offers several benefits. It contributes to improved system efficiency by ensuring that pressure levels are consistently monitored and maintained. This can lead to enhanced safety, as proper pressure management reduces the risk of system failures. Additionally, by maintaining optimal pressure levels, fleet operators may experience potential cost savings through reduced maintenance needs and improved fuel efficiency.

Installation Process

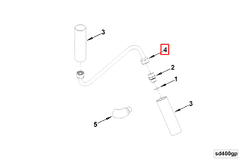

Installing the 4998830 Pressure Sensing Tube requires careful attention to detail. The process involves identifying the correct location for the tube within the truck’s system, ensuring all connections are secure, and verifying that the tube is properly aligned with other components. Tools such as wrenches and torque wrenches may be necessary, and precautions should be taken to avoid damage to the tube or surrounding parts.

Troubleshooting Common Issues

Common problems associated with the 4998830 Pressure Sensing Tube may include inaccurate readings, leaks, or connection issues. Troubleshooting steps can involve checking for proper alignment and secure connections, inspecting the tube for signs of wear or damage, and ensuring that the sensor or gauge is functioning correctly. Addressing these issues promptly can help maintain the tube’s performance and reliability.

Maintenance Tips

Regular maintenance practices are recommended to ensure the longevity and optimal performance of the 4998830 Pressure Sensing Tube. This includes periodic inspections for signs of wear, ensuring connections remain secure, and cleaning the tube as necessary to remove any debris or contaminants. Following manufacturer guidelines for maintenance can help prevent issues and extend the tube’s service life.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets. The company’s product range includes engines, powertrains, and related components, all designed to meet the demanding needs of various industries.

Pressure Sensing Tube (Part 4998830) in Cummins Engines

The Pressure Sensing Tube (Part 4998830) is a critical component in several Cummins engine models, ensuring accurate monitoring of pressure levels within the engine system. This part is integral to maintaining optimal engine performance and efficiency.

QSK19 and CM850 Engines

In the QSK19 and CM850 engines, the Pressure Sensing Tube is designed to provide precise readings of the pressure within the engine’s fuel system. This information is vital for the engine control unit (ECU) to adjust fuel delivery and ignition timing, ensuring the engine operates at peak efficiency. The tube’s placement and design allow it to withstand the high pressures and temperatures found in these industrial-grade engines.

MCRS Engines

For the MCRS engines, the Pressure Sensing Tube plays a similar role, but it is tailored to the specific needs of these engines. The MCRS engines are known for their robust construction and reliability, often used in heavy-duty applications. The Pressure Sensing Tube in these engines is engineered to provide accurate pressure data, which is crucial for maintaining the engine’s performance under demanding conditions.

Compatibility and Installation

The Pressure Sensing Tube (Part 4998830) is compatible with the QSK19, CM850, and MCRS engines, ensuring a seamless fit and function across these models. Installation of this part requires precision to ensure that it is correctly positioned to provide accurate pressure readings. Proper installation is essential to avoid any potential issues with engine performance or efficiency.

Importance of the Pressure Sensing Tube

The Pressure Sensing Tube is a key component in the engine’s diagnostic and control systems. It helps in detecting any anomalies in the pressure levels, which can be indicative of potential issues such as fuel system leaks, blockages, or other mechanical problems. By providing real-time data to the ECU, the tube ensures that the engine can make necessary adjustments to maintain optimal performance.

Role of Part 4998830 Pressure Sensing Tube in Engine Systems

In plumbing systems, the pressure sensing tube is employed to measure the pressure within the system. It is connected to various points in the plumbing network, allowing for the detection of pressure changes. This data is essential for maintaining optimal flow rates and ensuring that the system operates within safe pressure limits. The tube interfaces with pressure gauges or sensors, which convert the physical pressure into readable data. This information is then used to adjust the system as necessary, preventing issues such as leaks or bursts due to excessive pressure.

In engine monitoring systems, the 4998830 Pressure Sensing Tube plays a significant role in ensuring the engine operates efficiently and safely. It is typically connected to various engine components such as the fuel system, lubrication system, and exhaust. By measuring the pressure at these points, the tube provides vital data to the engine control unit (ECU). This data helps the ECU make real-time adjustments to fuel injection, ignition timing, and other parameters to optimize performance and reduce emissions. Additionally, the pressure sensing tube aids in detecting anomalies such as leaks or blockages, allowing for timely maintenance and preventing potential engine damage.

Conclusion

The Cummins 4998830 Pressure Sensing Tube is a vital component in the operation of commercial trucks and Cummins engines. Its role in monitoring and regulating pressure ensures the efficient and safe operation of these vehicles. By providing accurate pressure readings, it contributes to maintaining optimal performance and reliability. Regular maintenance and proper installation are essential to ensure the longevity and effectiveness of this part.

-

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩ -

Lakshminarayanan, P. A., & Nayak, N. S. (2011). Critical Component Wear in Heavy Duty Engines. John Wiley & Sons.

↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.