This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

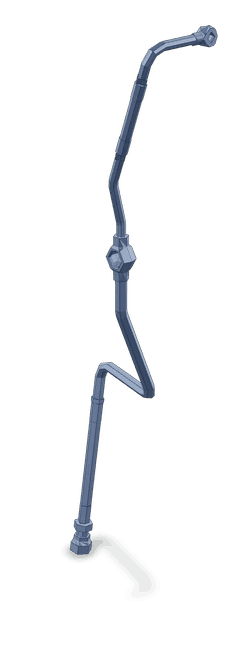

Introduction to the Cummins Tur Coolant Supply Tube

The Cummins Tur Coolant Supply Tube, part number 5255069, is a critical component in the cooling system of commercial trucks and heavy-duty vehicles. This article provides an in-depth understanding of the Tur Coolant Supply Tube, its functionality, and its importance in maintaining engine performance.

Basic Concepts Related to the Tur Coolant Supply Tube

The Tur Coolant Supply Tube is designed to transport coolant from the radiator to the engine block, ensuring that the engine maintains an optimal operating temperature. This tube is typically made from high-quality materials that can withstand the extreme conditions within the engine compartment, including high temperatures and pressures 1.

How the Tur Coolant Supply Tube Works

The Tur Coolant Supply Tube functions by channeling coolant through a series of passages within the engine block. The coolant absorbs heat from the engine and then flows back to the radiator, where it is cooled before being recirculated. This continuous cycle is crucial for preventing engine overheating and maintaining efficient performance 2.

Purpose of the Tur Coolant Supply Tube in Truck Engines

The primary role of the Tur Coolant Supply Tube is to ensure that the engine receives a consistent supply of coolant. This is vital for several reasons:

- Temperature Regulation: By maintaining the engine at an optimal temperature, the Tur Coolant Supply Tube helps to prevent overheating, which can lead to engine damage 3.

- Lubrication: The coolant also helps to lubricate certain parts of the engine, reducing wear and tear.

- Protection Against Corrosion: The coolant contains additives that protect the engine from corrosion and rust.

Troubleshooting and Maintenance

Proper maintenance of the Tur Coolant Supply Tube is essential for the longevity and efficiency of the cooling system. Here are some tips for troubleshooting and maintenance:

- Regular Inspections: Regularly inspect the Tur Coolant Supply Tube for signs of wear, leaks, or blockages. Any damage can compromise the cooling system’s effectiveness.

- Leak Detection: If coolant leaks are detected, it is crucial to address them promptly. Leaks can lead to coolant loss and engine overheating.

- Cleaning: Ensure that the Tur Coolant Supply Tube and its connections are free from debris and buildup. This can be achieved through regular cleaning and maintenance.

- Replacement: If the Tur Coolant Supply Tube is damaged or shows signs of wear, it should be replaced immediately. Using high-quality replacement parts, such as those from Cummins, ensures optimal performance and reliability.

Cummins: A Leader in Engine Technology

Cummins is a renowned manufacturer of diesel engines and related components, known for its commitment to quality and innovation. The Cummins Tur Coolant Supply Tube is engineered to meet the rigorous demands of commercial truck and heavy-duty vehicle applications. Cummins’ focus on research and development ensures that their parts are designed to provide reliable performance and durability.

Importance of the Tur Coolant Supply Tube in Fleet Operations

For fleet operators, the reliability of the Tur Coolant Supply Tube is paramount. Downtime due to engine overheating can result in significant financial losses and operational disruptions. By ensuring that the Tur Coolant Supply Tube is in good condition, fleet operators can maintain the efficiency and reliability of their vehicles, leading to cost savings and improved performance.

Role of Part 5255069 Tur Coolant Supply Tube in Engine Systems

The Part 5255069 Tur Coolant Supply Tube is an essential component in the efficient operation of various engine systems, particularly those involving the turbocharger and its associated plumbing.

Integration with Clocked Plumbing

In clocked plumbing systems, the Tur Coolant Supply Tube ensures a consistent and regulated flow of coolant. This is vital for maintaining the integrity and performance of the plumbing, which is often subjected to high pressures and temperatures. The tube’s precise fit and design help in minimizing leaks and ensuring that coolant reaches all necessary points within the system.

Function in Turbocharger Systems

When integrated with a turbocharger, the Tur Coolant Supply Tube plays a significant role in managing the thermal loads experienced by the turbocharger. By supplying coolant to the turbocharger, it helps in dissipating heat, thereby preventing overheating and potential damage to the turbocharger components. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions.

Coordination with Turbocharger Coolant Drain Tube

The Tur Coolant Supply Tube works in conjunction with the Turbocharger Coolant Drain Tube to create a closed-loop coolant system. The supply tube delivers coolant to the turbocharger, while the drain tube returns the used coolant back to the engine’s cooling system. This continuous circulation ensures that the turbocharger remains within optimal operating temperatures, enhancing its longevity and efficiency.

Role in Engine Kits

In comprehensive engine kits, the Tur Coolant Supply Tube is often included to ensure that all components receive the necessary coolant flow. This is especially important in aftermarket or high-performance engine kits where additional cooling may be required to handle increased power outputs and thermal loads. The tube’s role in these kits is to provide a reliable and efficient coolant pathway, supporting the overall performance and durability of the engine system.

Conclusion

This comprehensive guide provides a detailed understanding of the Cummins Tur Coolant Supply Tube, its functionality, and the importance of proper maintenance. By following these guidelines, engineers, mechanics, truck drivers, and fleet operators can ensure that their cooling systems operate efficiently, contributing to the overall performance and longevity of their vehicles.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.