5255737

Breather Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

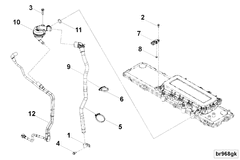

The Cummins 5255737 Breather Tube is a component designed for use in commercial trucks. Its purpose is to facilitate the release of pressure and contaminants from the engine crankcase. This part plays a role in maintaining the engine’s operational efficiency by ensuring that the crankcase does not become over-pressurized, which could lead to oil leaks and other mechanical issues 4.

Function and Operation

The breather tube operates by allowing air and contaminants to escape from the engine crankcase. As the engine runs, it produces blow-by gases that pass through the piston rings and enter the crankcase. The breather tube provides a pathway for these gases to exit, thus maintaining pressure equilibrium. It also allows for the release of moisture and other contaminants that could otherwise accumulate and degrade the quality of the engine oil 2.

Key Features

The Cummins 5255737 Breather Tube is constructed from durable materials to withstand the harsh conditions within a commercial truck engine. It features secure connection points for attachment to the crankcase and other components. The design includes elements that enhance its functionality, such as filters to trap larger particles before they exit the crankcase 3.

Benefits of Using a Breather Tube

A properly functioning breather tube contributes to improved engine performance by maintaining optimal crankcase pressure. It helps reduce wear on engine components by preventing the buildup of contaminants in the engine oil. Additionally, it enhances the longevity of the engine oil by allowing contaminants to be expelled, thus maintaining oil cleanliness and effectiveness 4.

Installation and Compatibility

When installing the Cummins 5255737 Breather Tube, it is important to follow the manufacturer’s guidelines to ensure proper fit and function. Compatibility with the truck’s engine model is crucial for the breather tube to perform as intended. It is recommended to consult the vehicle’s service manual or Cummins’ specifications to confirm compatibility and to understand any specific installation requirements 1.

Maintenance and Troubleshooting

Regular maintenance of the breather tube is important to ensure it continues to function correctly. This includes checking for blockages or damage that could impede its operation. Common issues with breather tubes may include clogging from debris or wear over time. Troubleshooting steps may involve cleaning or replacing the tube if necessary 2.

Safety Considerations

When working with the breather tube, it is important to observe safety practices. This includes ensuring the engine is cool before beginning any work and using the appropriate personal protective equipment. Care should be taken during installation and maintenance to avoid damage to the tube or surrounding components 3.

Environmental Impact

The proper function of the breather tube contributes to reducing emissions by ensuring the engine operates efficiently. By maintaining clean engine oil and preventing the release of contaminants into the environment, it plays a role in the overall environmental footprint of the truck 4.

Compatibility with Cummins Engines

The Breather Tube part 5255737, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is crucial for maintaining the engine’s health by allowing the release of gases and preventing the build-up of pressure within the engine’s crankcase. Here is how this part fits with various Cummins engines:

-

ISC CM2150, ISL CM2150, ISC8.3 CM2250, ISL9 CM2250: These engines, which include both the ISC and ISL series, are compatible with the Breather Tube part 5255737. This part ensures that the crankcase ventilation system operates efficiently, reducing the risk of oil contamination and pressure build-up.

-

QSC9 CM2250/QSL9 CM2250: The Breather Tube part 5255737 is also suitable for these models. These engines, part of the QSC and QSL series, benefit from the breather tube’s ability to manage crankcase gases effectively.

-

QSL9 CM2250, QSL9 CM2350 L102: These engines, which include the QSL9 CM2250 and the QSL9 CM2350 L102, are also compatible with the Breather Tube part 5255737. This part ensures that the crankcase ventilation system remains efficient, contributing to the overall performance and longevity of the engine.

By ensuring that the Breather Tube part 5255737 is correctly installed, engine operators can maintain the integrity of the crankcase ventilation system, leading to improved engine performance and reduced maintenance needs 1.

Role of Part 5255737 Breather Tube in Engine Systems

The Part 5255737 Breather Tube is a component in maintaining the health and efficiency of engine systems by facilitating the proper ventilation of the crankcase. This breather tube allows for the release of pressure and the expulsion of contaminants that accumulate within the crankcase during engine operation.

Interaction with the Crankcase

The breather tube is directly connected to the crankcase, which houses the crankshaft and connecting rods. As the engine runs, it generates heat and pressure within the crankcase. The breather tube provides a pathway for these byproducts to escape, preventing a buildup that could lead to increased wear on engine components and reduced performance 2.

Pressure Regulation

By allowing the escape of gases and vapors, the breather tube helps regulate the internal pressure of the crankcase. This regulation is vital for the proper functioning of the piston rings and cylinder walls, as excessive pressure can lead to oil leaks and compromised sealing 4.

Contaminant Removal

In addition to pressure relief, the breather tube plays a significant role in removing contaminants such as moisture and sludge that form within the crankcase. These contaminants, if left unchecked, can mix with the engine oil, leading to decreased lubrication efficiency and potential engine damage 3.

Integration with Other Systems

The breather tube often connects to other engine systems, such as the Positive Crankcase Ventilation (PCV) system. In this setup, the breather tube directs the expelled gases into the intake manifold, where they are re-burned in the combustion process. This not only helps in reducing emissions but also ensures that the engine operates with optimal efficiency 4.

Conclusion

In summary, the Part 5255737 Breather Tube is a key component in the ventilation and maintenance of the crankcase, contributing to the overall performance and longevity of the engine system. Proper installation, maintenance, and understanding of its role in engine systems are essential for ensuring the efficient operation of commercial truck engines.

-

Cummins Inc. (n.d.). Operation and Maintenance Manual for B4.5 CM2350 B129B. Bulletin Number 5411248.

↩ ↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩ ↩ ↩ -

Arora, S., Abkenar, A. T., & Jayasi, S. G. (2021). Heavyduty Electric Vehicles: From Concept to Reality. Elsevier.

↩ ↩ ↩ -

Kasab, J., & Strzelec, A. (2020). Automotive Emissions Regulations and Exhaust Aftertreatment Systems. SAE International.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.