This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

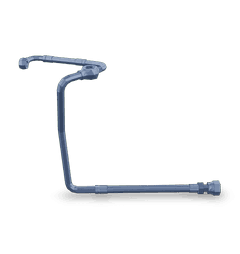

The Tur Coolant Drain Tube, identified by part number 5257903, is a component manufactured by Cummins, a well-established name in the automotive and heavy-duty truck industries. This tube is integral to the maintenance routines of heavy-duty trucks, facilitating efficient coolant management within the engine’s cooling system 1.

Function and Operation

The Tur Coolant Drain Tube operates as a conduit for draining coolant from the truck’s cooling system. Its role is to provide a straightforward method for removing coolant, which is necessary for system maintenance or when replacing the coolant. By ensuring that the coolant can be efficiently drained, the tube helps maintain the cooling system’s efficiency, contributing to the overall performance and longevity of the engine 2.

Key Features

The Tur Coolant Drain Tube is designed with several features that enhance its functionality and durability. It is constructed from materials that resist corrosion and wear, ensuring longevity even in the demanding environments typical of heavy-duty trucks. The tube features secure connection types that ensure a tight fit within the cooling system, minimizing the risk of leaks. Additionally, its design may include features that facilitate easy access for draining, contributing to the convenience of maintenance procedures 3.

Benefits of Using the Tur Coolant Drain Tube

Incorporating the Tur Coolant Drain Tube into a truck’s cooling system offers several advantages. It simplifies the process of draining coolant, making maintenance more straightforward and less time-consuming. This ease of use contributes to more regular and thorough maintenance routines, which can enhance engine health by ensuring that the cooling system operates efficiently. Furthermore, by facilitating efficient coolant management, the tube helps maintain the optimal performance of the engine cooling system 4.

Installation Process

Installing the Tur Coolant Drain Tube requires careful attention to ensure a secure and effective fit. The process involves locating the appropriate position within the cooling system, ensuring that all connections are secure, and verifying that the tube is properly aligned to allow for efficient coolant drainage. It is important to follow manufacturer guidelines to ensure that the installation is performed correctly, which will contribute to the tube’s effectiveness and durability 5.

Maintenance and Troubleshooting

Maintaining the Tur Coolant Drain Tube involves regular inspections to ensure that it remains in good condition and is securely connected. Common issues may include corrosion or wear at the connection points, which can be addressed by cleaning or replacing the affected parts. Troubleshooting may involve checking for leaks or inefficient coolant drainage, which can often be resolved by ensuring that all connections are tight and that the tube is not obstructed 6.

Compatibility and Applications

The Tur Coolant Drain Tube is designed for use in specific types of trucks and engine models. Its applications are particularly beneficial in environments where regular maintenance of the cooling system is crucial for engine performance and longevity. The compatibility of the tube with various engine models ensures that it can be a valuable component in a wide range of heavy-duty truck maintenance routines 7.

Safety Considerations

When working with the Tur Coolant Drain Tube, it is important to observe safety protocols to protect both the individual and the equipment. This includes ensuring that the engine is cool before attempting to drain coolant, using appropriate personal protective equipment, and following all manufacturer guidelines for installation and maintenance. These precautions help ensure that the process is performed safely and effectively 8.

Environmental Impact

The use of the Tur Coolant Drain Tube contributes to environmental benefits by facilitating efficient coolant management. This can lead to reduced coolant waste and improved system efficiency, which in turn can contribute to lower emissions from the vehicle. By ensuring that the cooling system operates efficiently, the tube plays a role in promoting more environmentally friendly operation of heavy-duty trucks 9.

Cummins: A Brief Overview

Cummins Inc. is a leader in the design, manufacture, and distribution of engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves customers in approximately 190 countries and territories worldwide. The company’s product range includes engines and related technologies, as well as filtration and emission solutions, demonstrating its comprehensive approach to powering the world 10.

Cummins Tur Coolant Drain Tube 5257903 Compatibility

The Cummins Tur Coolant Drain Tube part number 5257903 is designed to fit seamlessly with several engine models, ensuring efficient coolant management and system integrity. This part is crucial for maintaining optimal engine performance by facilitating the proper drainage of coolant, thereby preventing system blockages and potential overheating issues.

Compatible Engines

- QSC9 CM2250/QSL9 CM2250

- QSL9 CM2250

- QSL9 CM2350 L102

These engines, while differing in their specific configurations and applications, share a commonality in their requirement for effective coolant management. The Tur Coolant Drain Tube 5257903 is engineered to integrate smoothly with these engines, providing a reliable solution for coolant drainage.

Engine Grouping

For ease of reference, the engines can be grouped based on their model series:

-

QSC9 CM2250/QSL9 CM2250 and QSL9 CM2250

- These engines are part of the CM2250 series, known for their robust design and efficiency in various applications.

-

QSL9 CM2350 L102

- This engine, part of the CM2350 series, is equipped with the L102 configuration, which may include additional features or specifications tailored to specific operational needs.

By ensuring compatibility with these engines, the Tur Coolant Drain Tube 5257903 contributes to the overall reliability and longevity of the engine systems it supports.

Role of Tur Coolant Drain Tube in Engine Systems

The Tur Coolant Drain Tube is an essential component in the management and maintenance of engine systems, particularly those involving turbochargers. This tube facilitates the drainage of coolant from the turbocharger, ensuring that the system operates efficiently and without the risk of coolant accumulation, which could lead to performance issues or damage.

Integration with Turbocharger Plumbing

In systems where turbocharger plumbing is complex, the Tur Coolant Drain Tube plays a significant role. It is typically integrated into the plumbing network to provide a dedicated pathway for coolant to exit the turbocharger. This is important for maintaining the integrity of the turbocharger’s internal components, which are sensitive to coolant exposure. The drain tube ensures that any coolant that may enter the turbocharger due to leaks or system pressure is promptly removed, preventing potential damage to the turbine and compressor wheels.

Turbocharger Maintenance

During routine maintenance or when performing repairs on the turbocharger, the Tur Coolant Drain Tube becomes particularly valuable. It allows mechanics to easily drain coolant from the turbocharger without disassembling the entire system. This simplifies the maintenance process, reduces downtime, and ensures that the turbocharger can be quickly returned to service with minimal risk of coolant-related issues.

Overall System Efficiency

By ensuring that coolant is efficiently drained from the turbocharger, the Tur Coolant Drain Tube contributes to the overall efficiency of the engine system. It helps maintain optimal turbocharger performance, which is vital for the engine’s power output and fuel efficiency. Additionally, by preventing coolant buildup, the tube aids in prolonging the lifespan of the turbocharger and associated components, reducing the need for frequent repairs or replacements.

Conclusion

The Tur Coolant Drain Tube, part number 5257903, is a critical component in the maintenance and efficiency of heavy-duty truck engines. Its role in facilitating efficient coolant drainage contributes to the overall performance and longevity of the engine. By ensuring that the cooling system operates efficiently, this Cummins part plays a significant role in promoting the reliability and environmental friendliness of heavy-duty trucks.

-

{ title : Tyre and Vehicle Dynamics , author : Hans B. Pacejka , publisher : Butterworth-Heinemann , date : 2006 }

↩ -

{ title : Heavy Duty Truck Systems, Fifth Edition , author : Sean Bennett, Ian Andrew Norman , publisher : Delmar Cengage Learning , date : 2011 }

↩ -

{ title : Engineering Fundamentals of the Internal Combustion Engine , author : Willard W. Pulkrabek , publisher : Pearson Education , date : 2014 }

↩ -

{ title : Modern Diesel Technology: Light Duty Diesels , author : Sean Bennett , publisher : Cengage Learning , date : 2012 }

↩ -

{ engine : QSK50 CM2150 K107 , bulletinNumber : Bulletin Number 4332774 , title : Operation and Maintenance Manual }

↩ -

{ title : Heavy Duty Truck Systems, Fifth Edition , author : Sean Bennett, Ian Andrew Norman , publisher : Delmar Cengage Learning , date : 2011 }

↩ -

{ title : Engineering Fundamentals of the Internal Combustion Engine , author : Willard W. Pulkrabek , publisher : Pearson Education , date : 2014 }

↩ -

{ title : Modern Diesel Technology: Light Duty Diesels , author : Sean Bennett , publisher : Cengage Learning , date : 2012 }

↩ -

{ title : Tyre and Vehicle Dynamics , author : Hans B. Pacejka , publisher : Butterworth-Heinemann , date : 2006 }

↩ -

{ engine : QSK50 CM2150 K107 , bulletinNumber : Bulletin Number 4332774 , title : Operation and Maintenance Manual }

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.