This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

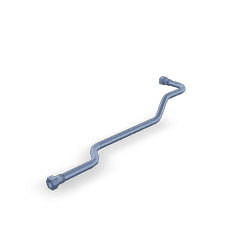

The Compressor Water Inlet Tube, identified by part number 5259187 and manufactured by Cummins, is a vital component in the operation of heavy-duty truck engines. This part is integral to the engine’s cooling and lubrication systems, contributing to its efficiency and reliability.

Basic Concepts and Functionality

The Compressor Water Inlet Tube operates on principles essential to the engine’s cooling and lubrication systems. It facilitates the introduction of water into the compressor, which is vital for maintaining optimal engine temperature and lubricating moving parts. The tube ensures a steady and regulated flow of water, contributing to the compressor’s efficient operation and longevity 1.

Purpose and Role in Truck Operation

In heavy-duty truck engines, the Compressor Water Inlet Tube plays a pivotal role. It aids in the cooling process by allowing water to enter the compressor, thereby helping to regulate the engine’s temperature. Additionally, it contributes to the lubrication system, ensuring that components within the compressor are adequately lubricated. This enhances the engine’s overall performance, efficiency, and durability 2.

Key Features

The 5259187 Compressor Water Inlet Tube is characterized by several key features that enhance its performance and durability. Its design ensures efficient water flow into the compressor. The materials used in its construction are selected for their ability to withstand the harsh conditions within a heavy-duty engine environment. Unique characteristics of this tube may include specific dimensions or coatings that further improve its functionality and resistance to wear 3.

Benefits

Utilizing the Compressor Water Inlet Tube offers several advantages. It contributes to improved engine cooling, which is vital for maintaining optimal engine performance and preventing overheating. Enhanced lubrication of compressor components leads to reduced friction and wear, extending the lifespan of these parts. The overall reliability of the engine is increased, which in turn contributes to the longevity and performance of the truck 4.

Installation and Compatibility

Proper installation of the Compressor Water Inlet Tube is crucial for its effective operation. Specific guidelines should be followed to ensure it is correctly positioned and secured within the engine system. Compatibility with various truck models and engine types is a consideration, ensuring that the tube fits and functions correctly within the intended application 5.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Inlet Tube is important for its continued optimal performance. This may include regular inspections for signs of wear or damage, and ensuring that the water flow is unobstructed. Troubleshooting common issues, such as leaks or reduced water flow, can often be addressed through simple adjustments or replacements, ensuring the tube continues to function effectively 6.

Cummins Overview

Cummins, the manufacturer of the Compressor Water Inlet Tube, has a long-standing reputation in the industry for quality and innovation. With a history of producing reliable diesel engines and components, Cummins is recognized for its commitment to excellence. Their role as a leading manufacturer in the industry underscores the quality and reliability of the 5259187 Compressor Water Inlet Tube 7.

Role of Part 5259187 Compressor Water Inlet Tube in Engine Systems

The 5259187 Compressor Water Inlet Tube is an essential component in the arrangement of engine systems, particularly in the management and regulation of the compressor coolant. This tube facilitates the precise delivery of water into the compressor, ensuring optimal cooling and performance of the compressor unit.

In the context of the compressor coolant system, the Compressor Water Inlet Tube works in conjunction with the coolant pump, thermostat, and various sensors to maintain the desired temperature within the compressor. It allows for the controlled flow of water, which absorbs heat from the compressor, thereby preventing overheating and ensuring efficient operation.

The integration of the Compressor Water Inlet Tube within the engine system also involves its connection to the water manifold and the radiator. This setup ensures a continuous circulation of coolant, which is vital for the sustained performance of the compressor under varying operational conditions.

Furthermore, the tube’s design and placement are engineered to minimize pressure loss and ensure uniform water distribution across the compressor. This is achieved through its strategic positioning within the engine’s coolant pathways, allowing for effective heat dissipation and maintaining the integrity of the compressor’s internal components.

Conclusion

In summary, the Compressor Water Inlet Tube plays a significant role in the effective functioning of the compressor coolant system, contributing to the overall reliability and performance of the engine. Its proper installation, maintenance, and integration within the engine system are crucial for optimal engine operation and longevity.

-

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Huzij, Robert; Spano, Angelo; Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504456, X12 CM2670 X121B engine.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504456, X12 CM2670 X121B engine.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504456, X12 CM2670 X121B engine.

↩ -

Cummins Inc. Fault Code Troubleshooting Manual. Bulletin Number 5504456, X12 CM2670 X121B engine.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.