This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbo Coolant Drain Tube (5291403) is a component manufactured by Cummins, a prominent name in the automotive industry, particularly known for its heavy-duty truck engines. This tube is integral to the engine’s cooling system, ensuring efficient operation and longevity of the turbocharger.

Function and Operation

This Cummins part operates within the engine cooling system by facilitating the drainage of coolant from the turbocharger. This process is vital for maintaining optimal engine temperature and preventing overheating, which can lead to engine damage. The tube allows coolant to exit the turbocharger housing, ensuring that the cooling system functions correctly and that the turbocharger remains within safe operating temperatures.

Key Features

The Turbo Coolant Drain Tube is designed with specific features to enhance its functionality and durability. It is constructed from high-quality materials that resist corrosion and withstand high temperatures, ensuring long-term reliability. The tube includes secure connection types that prevent leaks and ensure a tight fit within the engine’s cooling system. Unique design elements may include reinforced sections to handle pressure fluctuations and a smooth interior to facilitate efficient coolant flow.

Benefits

This part offers several advantages. It contributes to improved engine performance by ensuring the turbocharger operates within optimal temperature ranges. Enhanced cooling efficiency is achieved through the effective drainage of coolant, which helps maintain consistent engine temperatures. Additionally, the tube reduces the risk of coolant contamination within the turbocharger, which can lead to inefficiencies and potential damage.

Installation and Compatibility

Proper installation of the Turbo Coolant Drain Tube is crucial for its effective operation. Guidelines for installation include ensuring that all connections are secure and that the tube is correctly positioned within the engine’s cooling system. It is important to verify compatibility with the truck’s engine and cooling system to ensure seamless integration and optimal performance.

Maintenance and Troubleshooting

Routine maintenance of the Turbo Coolant Drain Tube involves regular inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections can prevent buildup that may impede coolant flow. Common issues may include leaks or blockages, which can be addressed by tightening connections or clearing obstructions. Regular maintenance helps ensure the tube continues to function effectively.

Safety Considerations

When working with the Turbo Coolant Drain Tube, it is important to observe safety precautions. This includes allowing the engine to cool before performing maintenance to avoid burns from hot components. Ensuring that the cooling system is properly pressurized before restarting the engine is also critical to prevent coolant leaks and system failures.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovation, quality, and reliability in the automotive industry. The company offers a wide range of products, including engines for heavy-duty trucks, which are known for their performance and durability 1.

Compatibility with Cummins Engines

The Turbo Coolant Drain Tube, identified by part number 5291403 and manufactured by Cummins, is a critical component in the cooling system of certain Cummins engines. This part is designed to facilitate the drainage of coolant from the turbocharger, ensuring efficient operation and longevity of the engine.

QSB6.7 CM2250

The QSB6.7 CM2250 engine is one of the models that benefit from the Turbo Coolant Drain Tube. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The Turbo Coolant Drain Tube in this engine ensures that any excess coolant is effectively removed from the turbocharger, preventing potential damage due to coolant accumulation.

Group Compatibility

The Turbo Coolant Drain Tube is compatible with a range of Cummins engines, particularly those that utilize turbochargers. This part is engineered to fit seamlessly into the cooling system architecture of these engines, providing a reliable method for coolant drainage. Its design ensures that it can effectively manage the flow of coolant, thereby maintaining optimal engine performance and preventing overheating issues.

Role in Engine Systems

The Turbo Coolant Drain Tube (5291403) is an essential component in the efficient operation of turbocharged engine systems. It is specifically designed to manage the coolant flow within the turbocharger, ensuring optimal performance and longevity of the engine.

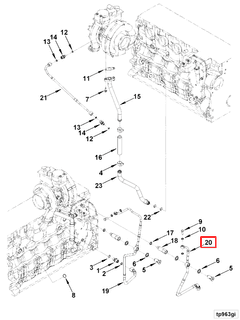

Integration with Plumbing Systems

In the context of engine plumbing, the Turbo Coolant Drain Tube plays a significant role in maintaining the integrity of the coolant system. It is connected to the turbocharger’s coolant passages, allowing for the effective drainage of coolant. This prevents the buildup of coolant within the turbocharger, which could lead to inefficiencies or damage. The tube is typically linked to the main coolant return line, ensuring that drained coolant is efficiently circulated back into the engine’s cooling system. This integration helps maintain consistent coolant levels and temperature, contributing to the overall stability of the engine’s operating conditions 2.

Function within the Turbocharger

Within the turbocharger, the Turbo Coolant Drain Tube is responsible for managing the coolant that is used to regulate the temperature of the turbocharger’s components. Turbochargers operate under extreme conditions, with high temperatures that can adversely affect their performance and lifespan. The coolant drain tube ensures that any excess coolant is properly drained away, preventing coolant contamination and maintaining the turbocharger’s efficiency. This is particularly important in high-performance engines where turbochargers are subjected to prolonged periods of operation under load.

Overall System Benefits

The effective drainage provided by the Turbo Coolant Drain Tube contributes to the turbocharger’s ability to maintain optimal boost pressure and efficiency. By ensuring that the turbocharger remains cool, the drain tube indirectly supports the engine’s power output and fuel efficiency. Additionally, it helps in reducing the risk of turbocharger failure due to overheating, thereby enhancing the reliability of the engine system as a whole.

Conclusion

In summary, the Turbo Coolant Drain Tube (5291403) is a vital component that works in conjunction with the engine’s plumbing and turbocharger to ensure efficient coolant management, thereby supporting the engine’s performance and durability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.