5291906

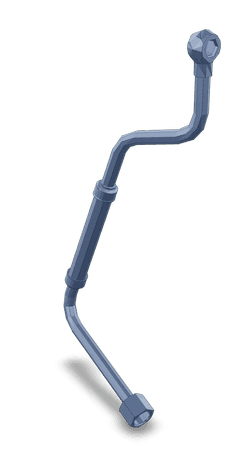

Tur Coolant Supply Tube

Cummins®

IN STOCK

2 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Tur Coolant Supply Tube, identified by part number 5291906, is a component manufactured by Cummins, a well-established name in the automotive industry, particularly known for its diesel engines and related components. This tube plays a role in the cooling system of heavy-duty trucks, ensuring the efficient operation of the turbocharger by managing coolant flow 1.

Purpose and Function

The Tur Coolant Supply Tube is designed to facilitate the flow of coolant to the turbocharger. By maintaining optimal operating temperatures, it helps in the efficient functioning of the turbocharger. This is achieved through a controlled supply of coolant, which absorbs excess heat generated during engine operation, thereby stabilizing the turbocharger’s temperature and enhancing its performance 2.

Key Features

The design and construction of the Tur Coolant Supply Tube are tailored for durability and efficiency. It is made from high-quality materials that are resistant to corrosion and high temperatures, ensuring longevity and reliable performance. The tube features secure connection types that prevent leaks and maintain a consistent coolant flow. Additionally, its design includes features that enhance its resilience under varying operating conditions 3.

Benefits

The Tur Coolant Supply Tube offers several advantages. It contributes to improved turbocharger efficiency by ensuring that the turbocharger operates within optimal temperature ranges. This, in turn, enhances engine longevity by reducing the stress on engine components. The tube also ensures reliable coolant flow under a variety of operating conditions, which is crucial for maintaining engine performance and efficiency.

Installation and Compatibility

Proper installation of the Tur Coolant Supply Tube is vital for its effective operation. It is designed to be compatible with specific truck models and engine types, ensuring a precise fit and function. Following the manufacturer’s guidelines for installation is recommended to ensure correct application and to avoid potential issues.

Maintenance and Troubleshooting

Regular maintenance of the Tur Coolant Supply Tube is important for its longevity and efficiency. This includes checking for leaks, ensuring secure connections, and inspecting the tube for signs of wear or damage. Common issues may include leaks or blockages, which can be diagnosed through visual inspection and pressure testing. Addressing these issues promptly can prevent more significant problems and ensure the continued efficient operation of the cooling system.

Performance Under Various Conditions

The Tur Coolant Supply Tube is designed to perform effectively under a range of driving conditions. Whether operating under heavy load, at high altitudes, or in extreme temperatures, the tube is engineered to maintain reliable coolant flow and temperature regulation. Its resilience and effectiveness under these conditions contribute to the overall performance and durability of the engine.

Cummins: A Brief Overview

Cummins Inc. is a leader in the automotive industry, with a rich history of innovation and quality in the production of diesel engines and related components. The company’s product range includes a variety of engines and parts designed for heavy-duty applications, reflecting its commitment to excellence and reliability in the automotive sector.

Compatibility with Cummins Engines

The Tur Coolant Supply Tube, identified by part number 5291906, is designed to ensure efficient coolant flow within the engine system. This part is integral to maintaining optimal engine temperature and performance. Below is a detailed description of its compatibility with specific Cummins engine models.

QSL9 Engine Series

The QSL9 engine series, known for its robust design and reliability, incorporates the Tur Coolant Supply Tube as a vital part of its cooling system. This tube facilitates the transfer of coolant from the supply source to the turbocharger, ensuring that the turbocharger operates within the desired temperature range. This is crucial for maintaining efficiency and longevity of the turbocharger, especially under high-load conditions.

CM2350 Engine

The CM2350 engine benefits significantly from the Tur Coolant Supply Tube, as it is designed to handle high-performance demands. This engine model is often used in heavy-duty applications where consistent and reliable cooling is paramount. The Tur Coolant Supply Tube ensures that the coolant reaches the turbocharger swiftly, preventing overheating and enhancing overall engine performance.

L102 Engine

The L102 engine, another high-performance model in the Cummins lineup, also integrates the Tur Coolant Supply Tube into its cooling system. This engine is typically used in applications requiring substantial power and durability. The Tur Coolant Supply Tube plays a role in maintaining the turbocharger’s temperature, which is essential for sustaining the engine’s high output levels.

Grouping of Engines

When considering the compatibility of the Tur Coolant Supply Tube across these engines, it is evident that this part is designed to fit seamlessly into the cooling systems of the QSL9, CM2350, and L102 engines. These engines, while differing in specific applications and performance metrics, share a common requirement for efficient coolant management. The Tur Coolant Supply Tube addresses this need by providing a reliable pathway for coolant flow, ensuring that the turbochargers and other critical components operate within their optimal temperature ranges.

Role of Part 5291906 Tur Coolant Supply Tube in Engine Systems

The 5291906 Tur Coolant Supply Tube is a component in the efficient operation of engine systems, particularly in relation to the turbocharger and overall plumbing setup.

Integration with Turbocharger

In turbocharged engine systems, the turbocharger operates under extreme conditions, generating significant heat. The 5291906 Tur Coolant Supply Tube plays a role in managing this heat by supplying coolant to the turbocharger. This ensures that the turbocharger maintains optimal operating temperatures, enhancing its efficiency and longevity. The tube is designed to withstand high pressures and temperatures, making it suitable for this demanding application.

Contribution to Plumbing System

The Tur Coolant Supply Tube is a vital part of the engine’s plumbing system. It facilitates the circulation of coolant throughout the engine, particularly to and from the turbocharger. This component ensures that coolant is delivered efficiently, reducing the risk of overheating and potential engine damage. The tube’s precise fit and robust construction are essential for maintaining the integrity of the coolant system, preventing leaks and ensuring consistent coolant flow.

Enhanced Engine Performance

By effectively managing the temperature of the turbocharger, the 5291906 Tur Coolant Supply Tube contributes to enhanced engine performance. It allows the turbocharger to operate at peak efficiency, which in turn improves overall engine power and responsiveness. The reliable delivery of coolant helps in maintaining the turbocharger’s performance under various driving conditions, from idle to high-speed operation.

Maintenance and Reliability

The inclusion of the 5291906 Tur Coolant Supply Tube in the engine system also simplifies maintenance procedures. Its design allows for easy installation and replacement, reducing downtime during servicing. The tube’s durability ensures that it can withstand the rigors of engine operation, providing long-term reliability and performance. Regular inspection and maintenance of this component are recommended to ensure the continued efficient operation of the turbocharger and the engine as a whole.

Conclusion

The Tur Coolant Supply Tube (Part #5291906) by Cummins is a critical component in the cooling systems of heavy-duty engines, ensuring efficient operation of the turbocharger and overall engine performance. Its design, compatibility with specific Cummins engines, and role in maintaining optimal coolant flow make it an essential part for those seeking reliability and efficiency in their engine systems.

-

Lakshminarayanan, P. A., & Kumar, A. (2020). Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer Nature.

↩ -

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩ -

Cummins Inc. (n.d.). Owners Manual for F3.8 F102, Bulletin Number 4325986.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.