This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

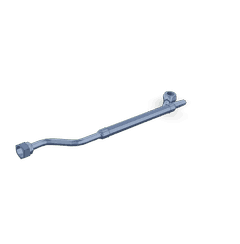

The Tur Coolant Drain Tube (part number 5293503) is a component manufactured by Cummins, designed for use in the cooling systems of heavy-duty trucks. This part facilitates the drainage of coolant from the system, ensuring that the cooling process remains efficient and effective. By allowing for the periodic removal of coolant, it helps maintain the integrity and performance of the engine cooling system.

Function and Operation

The Tur Coolant Drain Tube operates by providing a pathway for coolant to exit the system during maintenance procedures. When the drain valve is opened, coolant flows through the tube and out of the system, allowing for the replacement of old coolant with fresh coolant. This process is vital for removing contaminants and ensuring that the coolant mixture remains optimal for engine cooling 1. The tube’s design ensures a smooth and controlled flow of coolant, minimizing the risk of spills and ensuring that the drainage process is both efficient and safe.

Key Features

The Tur Coolant Drain Tube is constructed from durable materials that resist corrosion and wear, ensuring longevity and reliability 2. Its design includes a secure fitting mechanism that prevents leaks and ensures a tight seal within the cooling system. Additionally, the tube is engineered to withstand high temperatures and pressures, making it suitable for the demanding conditions found in heavy-duty truck engines. Unique attributes such as its easy-to-use drain valve and robust construction enhance its performance and usability.

Benefits

The use of the Tur Coolant Drain Tube offers several advantages. It improves coolant flow by ensuring that the system is free from contaminants, which can otherwise impede the cooling process. Reduced maintenance requirements are another benefit, as the efficient drainage process simplifies coolant changes and system flushes. Enhanced engine protection is also provided, as clean coolant is crucial for maintaining optimal engine temperature and preventing overheating 3.

Installation Process

Installing the Tur Coolant Drain Tube involves several steps to ensure proper integration into the truck’s cooling system. First, the system should be cooled down to prevent burns from hot coolant. Next, locate the drain point within the cooling system and connect the tube using the provided fittings. Ensure that all connections are secure to prevent leaks. Finally, test the system by briefly opening the drain valve to confirm that coolant flows smoothly through the tube. Tools required may include wrenches for securing fittings and a container for collecting drained coolant.

Maintenance and Troubleshooting

Regular maintenance of the Tur Coolant Drain Tube involves checking for signs of wear or corrosion and ensuring that all connections remain secure. It is important to perform coolant changes according to the manufacturer’s recommendations to prevent buildup of contaminants within the system. Common issues may include leaks at connection points or a blocked drain tube. Troubleshooting steps include inspecting connections for tightness, cleaning or replacing the tube if necessary, and ensuring that the drain valve operates smoothly.

Compatibility and Applications

The Tur Coolant Drain Tube is designed for use in a variety of heavy-duty truck models and engines. It is commonly applied in systems where efficient coolant drainage is required to maintain engine performance and longevity. Specific compatibility details, including model and series information, should be consulted to ensure the part is suitable for the intended application.

Safety Considerations

When working with the Tur Coolant Drain Tube, it is important to observe several safety precautions. Always allow the engine to cool before attempting any maintenance to avoid burns from hot coolant. Wear personal protective equipment, including gloves and safety glasses, to protect against spills and debris. Handle the tube and fittings carefully to avoid damage, and follow all manufacturer guidelines for installation and maintenance.

Environmental Impact

The use and disposal of the Tur Coolant Drain Tube should be considered in terms of environmental impact. Proper disposal of used coolant is crucial to prevent environmental contamination. Many coolants are recyclable, and facilities for recycling should be utilized whenever possible. The tube itself, made from durable materials, is designed for long-term use, reducing the need for frequent replacements and minimizing waste.

Conclusion

The Tur Coolant Drain Tube (part number 5293503) is a vital component in the maintenance and efficiency of heavy-duty truck cooling systems. Its role in facilitating the drainage of coolant ensures that the cooling process remains effective, contaminants are removed, and engine performance is maintained. Proper installation, regular maintenance, and adherence to safety guidelines are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.