This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

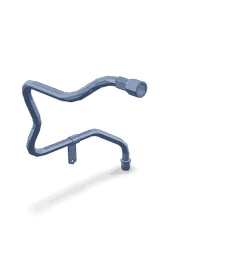

The Cummins 5297926 Breather Tube is a component designed for use in heavy-duty truck engines. Its purpose is to facilitate the release of pressure and contaminants from the engine’s crankcase. This part contributes to the overall efficiency and reliability of the engine by ensuring that the crankcase remains at an optimal pressure and free from harmful contaminants 2.

Basic Concepts of Breather Tubes

A breather tube is a component found in engine systems that allows for the release of pressure and the expulsion of contaminants from the crankcase. It operates on the principle of maintaining a balanced pressure within the crankcase, which is crucial for the proper functioning of the engine. As the engine operates, it generates pressure and contaminants within the crankcase. The breather tube provides a pathway for these elements to escape, thus preventing buildup that could lead to engine damage 3.

Purpose of the Cummins 5297926 Breather Tube

The Cummins 5297926 Breather Tube plays a role in the operation of a truck by allowing for the controlled release of pressure and contaminants from the engine’s crankcase. This function is vital for maintaining engine health and performance. By ensuring that the crankcase does not become over-pressurized or contaminated, the breather tube helps to protect the engine’s internal components and contributes to its longevity and efficiency 1.

Key Features

The Cummins 5297926 Breather Tube is constructed from durable materials that are resistant to the high temperatures and pressures found within an engine environment. Its design includes features that enhance its performance, such as a filtration system that captures contaminants before they can escape into the atmosphere. Additionally, the tube is engineered to fit securely within the engine system, ensuring a reliable seal and efficient operation 4.

Benefits

The use of the Cummins 5297926 Breather Tube offers several benefits. It contributes to improved engine longevity by maintaining optimal crankcase pressure and cleanliness. Enhanced engine performance is also a result of the breather tube’s function, as it helps to ensure that the engine operates under the best possible conditions. Furthermore, the breather tube’s reliable operation under various conditions adds to the overall dependability of the engine system 2.

Installation Process

Installing the Cummins 5297926 Breather Tube requires careful attention to ensure a proper fit and function. The process involves locating the correct position within the engine system, securing the tube in place, and verifying that all connections are tight and secure. Tools and equipment necessary for installation may include wrenches and sealants, depending on the specific requirements of the engine system 3.

Maintenance Tips

Regular maintenance of the Cummins 5297926 Breather Tube is important for ensuring its optimal performance. This includes periodic inspections to check for signs of wear or damage, as well as cleaning the filtration system to remove any accumulated contaminants. Following the manufacturer’s recommended maintenance schedule will help to ensure the breather tube continues to operate efficiently 1.

Troubleshooting Common Issues

Common issues associated with breather tubes include leaks or blockages. These problems can often be identified through visual inspection or by monitoring the engine’s performance. Troubleshooting steps may involve checking connections for tightness, cleaning or replacing the filtration system, or inspecting the tube for signs of damage. Addressing these issues promptly can help to prevent more serious engine problems 4.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the automotive industry, particularly in the heavy-duty truck sector. The company’s product range includes a variety of components and systems designed to enhance the performance and reliability of engines 2.

Breather Tube Part 5297926 in Cummins Engines

The Breather Tube part 5297926 is a critical component in the Cummins QSB6.7 CM2250 and QSB6.7 CM2350 B105 engines. This part is integral to the engine’s ventilation system, ensuring that the crankcase is properly ventilated to prevent the buildup of harmful gases and maintain optimal engine performance.

In the QSB6.7 CM2250 engine, the Breather Tube part 5297926 connects the crankcase ventilation system to the intake manifold. This connection allows for the expulsion of gases that are produced during the combustion process, which helps to maintain the air-fuel mixture and prevent pressure buildup within the crankcase.

Similarly, in the QSB6.7 CM2350 B105 engine, the Breather Tube part 5297926 serves the same purpose. It ensures that the crankcase is ventilated effectively, which is crucial for the longevity and efficiency of the engine. The design and placement of this part are engineered to work seamlessly with the specific architecture of the QSB6.7 CM2350 B105 engine, ensuring that it meets the stringent performance standards set by Cummins.

Both engines rely on the Breather Tube part 5297926 to maintain a healthy balance of gases within the crankcase, which is essential for preventing engine damage and ensuring smooth operation. This part is a testament to Cummins’ commitment to quality and reliability, providing a critical function in the overall engine design 3.

Role of Part 5297926 Breather Tube in Engine Systems

The part 5297926 Breather Tube is an essential component in the efficient operation of engine systems, particularly in relation to the crankcase breather and plumbing systems.

In the context of the crankcase breather system, the breather tube facilitates the release of pressure that builds up within the crankcase. This pressure is a byproduct of the combustion process, where gases and vapors are produced. The breather tube allows these gases to escape, preventing a buildup that could lead to leaks or damage to seals and gaskets. It ensures that the crankcase maintains a stable pressure, which is important for the proper functioning of the engine’s moving parts.

Regarding the plumbing system, the breather tube is integrated into the network of hoses and pipes that manage fluid and gas flow within the engine. It connects to various components, allowing for the controlled venting of gases. This integration is vital for maintaining the overall balance of pressures within the engine, contributing to its longevity and performance.

The breather tube also plays a role in environmental considerations by directing the released gases to a location where they can be safely dispersed or recirculated back into the intake system. This reduces the emission of harmful gases into the atmosphere, aligning with environmental regulations and standards.

In summary, the part 5297926 Breather Tube is a key element in the engine’s breather system, working in conjunction with the crankcase breather and the engine’s plumbing to ensure efficient pressure management, component protection, and environmental compliance 4.

Conclusion

The Cummins 5297926 Breather Tube is a vital component in heavy-duty truck engines, ensuring the efficient release of pressure and contaminants from the crankcase. Its durable construction, integrated filtration system, and secure fit within the engine system contribute to enhanced engine performance, longevity, and environmental compliance. Regular maintenance and prompt troubleshooting of common issues are essential for the optimal operation of this part, reflecting Cummins’ commitment to quality and reliability in engine design.

-

Livesey, A. (2000). The Repair of Vehicle Bodies. Elevier.

↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ -

Norman, A. (2016). Diesel Technology Fundamentals Service Repair Eighth Edition. The Goodheart-Willcox Company Inc.

↩ ↩ ↩ -

Atkins, R. D. (2009). An Introduction to Engine Testing and Development. SAE International.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.