This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

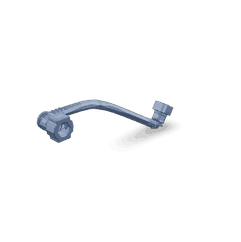

The Compressor Water Outlet Tube, identified by Part #5303329, is a component manufactured by Cummins, a leader in diesel engines and related technologies. This tube is integral to the cooling systems of heavy-duty truck engines, facilitating efficient management of engine temperatures through the regulation of coolant flow 1.

Function and Operation

The Compressor Water Outlet Tube operates within the engine’s cooling system by directing the flow of coolant from the compressor. It ensures that the coolant, after absorbing heat from the compressor, is efficiently routed to other parts of the engine cooling system where it can dissipate this heat, thus maintaining a stable operating temperature for the engine 2.

Purpose and Role in Truck Operation

In the context of heavy-duty truck engines, the Compressor Water Outlet Tube serves a specific purpose by contributing to the maintenance of optimal engine temperature. This is achieved through its role in the coolant circulation process, which is vital for preventing engine overheating and ensuring consistent performance under various operating conditions 3.

Key Features

The Compressor Water Outlet Tube is characterized by several key features that enhance its functionality and reliability. These include a durable construction designed to withstand the rigors of heavy-duty use, precise engineering that ensures a perfect fit and efficient operation within Cummins engines, and a design that promotes compatibility with a wide range of engine configurations.

Benefits

Utilizing the Compressor Water Outlet Tube offers several benefits. These include improved engine efficiency due to effective heat management, enhanced durability that contributes to the longevity of the engine cooling system, and reliable performance even under demanding conditions. These attributes make it a valuable component for maintaining the overall health and performance of heavy-duty truck engines.

Installation and Compatibility

Proper installation of the Compressor Water Outlet Tube is crucial for ensuring its effective operation within Cummins engines. Installation procedures should follow manufacturer guidelines to ensure compatibility and optimal performance. Specific requirements may include precise alignment and secure fastening to prevent leaks and ensure efficient coolant flow.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Outlet Tube involves regular inspections for signs of wear, corrosion, or damage. Troubleshooting common issues such as leaks or blockages may require cleaning or replacing the tube, depending on the severity of the problem. Adhering to maintenance schedules and addressing issues promptly can help maintain the efficiency and reliability of the engine cooling system.

Cummins Overview

Cummins, the manufacturer of the Compressor Water Outlet Tube, has a long-standing reputation in the automotive and heavy-duty truck industries. With a history of innovation and commitment to quality, Cummins is recognized for producing high-quality components that enhance the performance and reliability of engines. Their dedication to excellence is reflected in the design and manufacturing of their automotive components, including the Compressor Water Outlet Tube.

Compatibility with Cummins Engines

The Compressor Water Outlet Tube, identified by part number 5303329 and manufactured by Cummins, is a critical component in the cooling system of certain Cummins engines. This part is designed to efficiently manage the flow of coolant from the compressor to the radiator, ensuring optimal engine temperature regulation.

F3.8 Engine

In the F3.8 engine, the Compressor Water Outlet Tube plays a pivotal role in maintaining the integrity of the cooling system. It connects the compressor to the radiator, facilitating the transfer of coolant and preventing overheating. This part is engineered to withstand the high pressures and temperatures typical of the F3.8 engine, ensuring durability and reliability.

F102 Engine

Similarly, in the F102 engine, the Compressor Water Outlet Tube is integral to the cooling process. It ensures that the coolant flows smoothly from the compressor to the radiator, helping to maintain the engine’s operating temperature within safe limits. The design of this part for the F102 engine reflects Cummins’ commitment to quality and performance, providing a seamless fit and function within the engine’s cooling system.

Grouping of Engines

The Compressor Water Outlet Tube (5303329) is compatible with both the F3.8 and F102 engines, highlighting its versatility and importance in Cummins’ engine lineup. This part’s design and engineering are tailored to meet the specific needs of these engines, ensuring efficient coolant flow and reliable performance.

Role of 5303329 Compressor Water Outlet Tube in Engine Systems

The 5303329 Compressor Water Outlet Tube is an integral component in the arrangement of engine systems, particularly in the management and regulation of the compressor coolant. This tube facilitates the efficient transfer of coolant from the compressor to other parts of the engine system, ensuring that the compressor operates within optimal temperature ranges.

In the context of the compressor coolant system, the Compressor Water Outlet Tube works in conjunction with the compressor, coolant passages, and the engine’s cooling system. It allows for the precise distribution of coolant, which is essential for maintaining the compressor’s performance and longevity. The tube’s design ensures that coolant is delivered consistently, preventing overheating and potential damage to the compressor.

Additionally, the Compressor Water Outlet Tube interacts with the engine’s thermostat and cooling fan, contributing to the overall thermal management of the engine. By ensuring that the compressor remains at an appropriate temperature, the tube helps in maintaining the efficiency and reliability of the engine system.

This component is also involved in the regulation of pressure within the coolant system. It helps in balancing the pressure across different parts of the engine, which is vital for the smooth operation of the compressor and other interconnected systems. The tube’s role in pressure management is particularly important during high-load operations, where the compressor’s demand for coolant increases.

Overall, the Compressor Water Outlet Tube is a key element in the intricate network of components that make up the engine’s cooling and thermal management systems. Its function is to ensure that the compressor receives the right amount of coolant at the right temperature and pressure, contributing to the engine’s overall performance and durability.

Conclusion

The Compressor Water Outlet Tube (5303329) is a vital component in the cooling systems of Cummins engines, ensuring efficient management of engine temperatures and contributing to the overall performance and reliability of heavy-duty truck engines. Its durable construction, precise engineering, and compatibility with various engine configurations make it an essential part of the engine’s cooling and thermal management systems.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Department of Energy. Department of Energy Fundamentals Handbook. Department of Energy, 2015.

↩ -

Garrett, TK, Newton, K, Steeds, W. The Motor Vehicle. Reed Educational and Professional Publishing Ltd, 2001.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.