This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

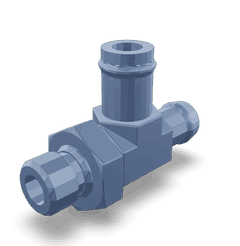

The 5332120 Tube Connector, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the industry, produces a range of parts that contribute to the efficiency and reliability of commercial vehicles. Tube connectors, in general, play a significant role in fluid systems by facilitating the transfer of liquids or gases. This Cummins part is specifically engineered to integrate into various fluid systems within commercial trucks, ensuring seamless operation and performance.

Basic Concepts of Tube Connectors

Tube connectors are devices used to join tubes or pipes in fluid systems, allowing for the transfer of liquids or gases between different components. They are crucial in maintaining the integrity of the system by providing secure and leak-proof connections. In various applications, tube connectors ensure that the flow of fluids is uninterrupted and that the system operates efficiently. They come in different designs and materials to suit the specific requirements of the application they are intended for 1.

Purpose of the 5332120 Tube Connector

The 5332120 Tube Connector is designed to play a specific role in the operation of commercial trucks. It integrates into the truck’s fluid systems, which may include fuel, hydraulic, or coolant systems. By providing a secure connection between tubes, it ensures that the transfer of fluids is efficient and reliable. This connector is part of the system that maintains the truck’s performance by ensuring that all fluid systems operate as intended.

Key Features

The 5332120 Tube Connector boasts several primary features that enhance its performance and durability. It is composed of materials that are resistant to corrosion and wear, ensuring longevity in demanding environments. The design attributes of this connector include precision engineering to ensure a tight seal, reducing the risk of leaks. Additionally, it may feature unique characteristics such as easy installation mechanisms or compatibility with a wide range of tube sizes and types.

Benefits

Using the 5332120 Tube Connector offers several advantages. It contributes to improved system efficiency by ensuring a secure and leak-proof connection. The reliability of this connector reduces the likelihood of system failures, which can be critical in commercial truck operations. Ease of installation is another benefit, allowing for quick replacement or integration into existing systems. These advantages contribute to overall truck performance and can simplify maintenance routines 2.

Installation and Compatibility

Proper installation of the 5332120 Tube Connector involves following specific procedures to ensure a secure and efficient connection. This may include the use of certain tools or additional components to facilitate the process. Compatibility with various truck models and systems is an important consideration, ensuring that the connector can be used across different applications without issues.

Troubleshooting and Maintenance

Common issues that may arise with tube connectors include leaks or loose connections. Troubleshooting steps may involve checking for proper installation, ensuring that all components are secure, and inspecting for signs of wear or damage. Maintenance tips to ensure the longevity and optimal performance of the 5332120 Tube Connector include regular inspections for signs of corrosion or wear, and replacing the connector if any issues are detected.

Safety Considerations

When working with tube connectors, it is important to observe certain safety practices. This includes proper handling during installation and maintenance to avoid injuries or damage to the component. Improper installation or maintenance can lead to system failures, which may have safety implications for the operation of the truck. Therefore, adhering to recommended practices is vital 3.

Cummins Overview

Cummins Inc. is a company with a rich history in the commercial truck industry, known for its wide range of products that contribute to the efficiency and reliability of commercial vehicles. The reputation of Cummins components, like the 5332120 Tube Connector, is built on a foundation of quality and performance. Professionals in the industry trust Cummins for its commitment to producing parts that meet the demanding requirements of commercial truck operations.

Role of Part 5332120 Tube Connector in Engine Systems

The 5332120 Tube Connector is an essential component that facilitates the secure and efficient connection of various engine system components. In the context of plumbing within engine systems, this tube connector ensures a leak-free and robust linkage between different fluid pathways, enhancing the overall reliability of the system.

When integrated with the cabin heater, the tube connector plays a significant role in maintaining the proper flow of coolant. This ensures that the heater core receives an adequate supply of heated fluid, which is vital for providing consistent and effective cabin heating. The secure connection provided by the tube connector prevents any coolant loss, thereby maintaining the efficiency of the heating system.

In the thermostat housing assembly, the tube connector is responsible for connecting the thermostat housing to the engine’s cooling system. This connection is important for regulating the flow of coolant based on the engine’s temperature. The tube connector ensures that the coolant circulates efficiently through the engine, contributing to optimal thermal management and preventing overheating.

Overall, the 5332120 Tube Connector is integral to the functioning of these engine components, ensuring secure, leak-free connections that are essential for the efficient operation of the engine’s cooling and heating systems.

Conclusion

The 5332120 Tube Connector by Cummins is a vital component in the fluid systems of commercial trucks, ensuring efficient and reliable operation. Its design and features contribute to the overall performance and maintenance ease of the vehicles it serves. Proper installation, regular maintenance, and adherence to safety practices are crucial for maximizing the benefits of this part.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.