This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

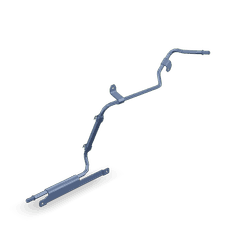

The Compressor Water Outlet Tube (5334700) by Cummins is a critical component designed for use in heavy-duty trucks. It plays a significant role within the engine’s cooling system, contributing to the overall efficiency and performance of the vehicle. This part is essential for maintaining the engine’s operational temperature, ensuring smooth and efficient operation under various conditions 1.

Basic Concepts

Understanding the fundamental principles behind the operation of the Compressor Water Outlet Tube is key to appreciating its role within the engine cooling system. This tube facilitates the flow of coolant from the compressor to other parts of the engine, helping to regulate temperature. It interacts with other components such as the radiator, thermostat, and water pump, working in concert to maintain an optimal engine temperature 2.

Purpose and Function

The Compressor Water Outlet Tube aids in the distribution of coolant, ensuring that the engine maintains an optimal operating temperature. This is vital for efficiency and longevity. By efficiently routing coolant, the tube helps prevent overheating, which can lead to engine damage, and ensures that the engine operates within its designed parameters 3.

Key Features

This Cummins part is characterized by its robust design and the materials used in its construction. It is engineered to withstand the high pressures and temperatures associated with heavy-duty truck engines. Its design includes features that enhance its performance and durability, such as precise manufacturing tolerances and corrosion-resistant materials.

Benefits

The advantages provided by the Compressor Water Outlet Tube include improved engine performance and enhanced durability. By ensuring efficient coolant flow, it contributes to maintaining optimal engine temperature, which can lead to better fuel efficiency and reduced wear on engine components. Additionally, its durable construction can result in potential cost savings through reduced maintenance and replacement needs.

Installation and Integration

Proper installation of the Compressor Water Outlet Tube within the truck’s engine system is crucial for its effective operation. This process involves ensuring that all connections are secure and that the tube is correctly positioned within the engine’s cooling system. It may require specific tools and knowledge of the engine’s layout to ensure successful integration.

Maintenance and Care

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the Compressor Water Outlet Tube. This includes regular inspections for signs of wear or damage, and cleaning procedures to remove any buildup that could impede coolant flow. Adhering to manufacturer-recommended inspection intervals can help identify issues before they lead to more significant problems.

Troubleshooting Common Issues

Frequent problems associated with the Compressor Water Outlet Tube can include leaks, blockages, or damage from corrosion. Diagnostic steps to address these issues may involve inspecting the tube for physical damage, checking for proper coolant flow, and ensuring that all connections are secure. Potential solutions can range from cleaning and repairing minor damage to replacing the tube if it is severely compromised.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation within the automotive and heavy-duty truck industries. Its product range includes a variety of components and systems designed to enhance the performance, efficiency, and reliability of vehicles and equipment.

Role of Part 5334700 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube (5334700) is integral to the efficient operation of engine systems, particularly in the context of compressor coolant management. This component facilitates the controlled exit of water from the compressor, ensuring that the coolant is effectively circulated and managed within the system.

In the arrangement of engine components, the Compressor Water Outlet Tube works in conjunction with the compressor coolant system. Its primary function is to direct the flow of water away from the compressor, which is essential for maintaining optimal operating temperatures and preventing overheating.

The tube is strategically positioned to connect to the compressor coolant passages, allowing for a seamless transition of water from the compressor to the rest of the cooling system. This ensures that the coolant is efficiently distributed, enhancing the overall performance and reliability of the engine.

By integrating the Compressor Water Outlet Tube into the engine’s coolant system, engineers and mechanics can ensure that the compressor operates within safe temperature ranges, thereby prolonging the lifespan of the component and improving the engine’s efficiency. The tube’s role in managing the flow of coolant is fundamental to the stable and effective operation of the engine system.

Conclusion

The Compressor Water Outlet Tube (5334700) by Cummins is a vital component in the cooling systems of heavy-duty trucks, ensuring efficient thermal management and engine performance. Its robust design, durable construction, and precise engineering contribute to the overall reliability and efficiency of the engine. Proper installation, maintenance, and timely troubleshooting are essential for maximizing the benefits of this part, ensuring the longevity and optimal operation of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.