This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

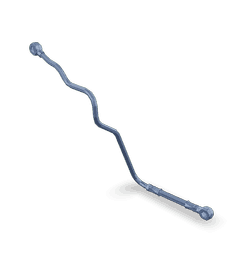

The Tur Coolant Drain Tube, identified by part number 5340837, is a component manufactured by Cummins, a well-established name in the diesel engine industry. This part is integral to the maintenance of heavy-duty trucks, specifically within the cooling systems of turbocharged engines. The Tur Coolant Drain Tube is designed to facilitate the efficient drainage of coolant from the turbocharger, playing a role in maintaining optimal engine temperature and ensuring the longevity of the engine 1.

Basic Concepts of Tur Coolant Drain Tubes

Coolant drain tubes in turbocharged engines serve a fundamental purpose: they help manage the heat generated by the turbocharger. Turbochargers compress air entering the engine, which increases the air’s temperature. To prevent overheating, coolant systems are employed to absorb and dissipate this heat. The coolant drain tube allows for the removal of coolant that has absorbed heat, thus maintaining a stable engine temperature 2.

Purpose and Function of the Tur Coolant Drain Tube

The Tur Coolant Drain Tube enables the drainage of coolant from the turbocharger. This process is vital for efficient heat management. By allowing coolant to be drained and replaced, the tube helps ensure that the coolant remains at an effective temperature for heat absorption. This continuous cycle is fundamental to preventing engine overheating and maintaining engine efficiency 3.

Key Features of the Cummins Tur Coolant Drain Tube (Part #5340837)

The Cummins Tur Coolant Drain Tube is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and high temperatures, ensuring longevity in demanding environments. The design of the tube includes precise fittings and connections that ensure a secure and leak-free installation. Additionally, the tube may feature unique attributes such as reinforced sections to withstand pressure fluctuations within the cooling system.

Benefits of Using the Cummins Tur Coolant Drain Tube

Utilizing the Cummins Tur Coolant Drain Tube offers several advantages. It contributes to improved engine longevity by ensuring efficient heat management, which reduces the risk of overheating-related damage. The tube also enhances cooling efficiency, leading to more stable engine temperatures under varying operating conditions. Furthermore, by maintaining optimal coolant flow, the tube helps reduce the likelihood of coolant-related issues, such as leaks or blockages, which can lead to engine damage.

Installation and Compatibility

Proper installation of the Tur Coolant Drain Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure compatibility with the engine’s cooling system. Specific requirements for integration may vary depending on the engine model, so it is important to consult the installation instructions provided by Cummins for detailed guidance.

Troubleshooting Common Issues

Common issues associated with Tur Coolant Drain Tubes include leaks, blockages, or malfunctions due to wear and tear. Troubleshooting these problems involves inspecting the tube for signs of damage, ensuring connections are secure, and checking for any obstructions within the coolant system. Regular maintenance and timely replacement of worn components can help prevent these issues.

Maintenance and Care

Regular maintenance of the Tur Coolant Drain Tube is important for ensuring its effectiveness and longevity. This includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the tube and its connections can help prevent blockages and ensure smooth coolant flow. Replacement should be considered if the tube shows significant signs of wear or if coolant leaks are detected.

Cummins: A Brief Overview

Cummins Inc. is a leader in the diesel engine manufacturing industry, with a history of innovation and commitment to quality. The company’s expertise in engine technology and components, including cooling system parts like the Tur Coolant Drain Tube, underscores its role in providing reliable and efficient solutions for heavy-duty trucks. Cummins’ dedication to advancing automotive technology ensures that its components meet the high demands of modern engines.

Role of Part 5340837 Tur Coolant Drain Tube in Engine Systems

The Part 5340837 Tur Coolant Drain Tube is an integral component in the efficient operation of engine systems that incorporate a turbocharger. This tube is specifically designed to facilitate the drainage of coolant from the turbocharger cooling system, ensuring that the system operates within optimal temperature ranges.

Integration with Plumbing Systems

In the context of engine plumbing, the Tur Coolant Drain Tube connects to the lowermost point of the turbocharger coolant passages. This placement ensures that any accumulated coolant, which may contain contaminants or has reached the end of its service life, can be effectively drained. The tube is typically routed to a collection point, such as a drain pan or a designated coolant recovery tank, allowing for easy disposal or recycling of the used coolant.

Interaction with Turbocharger Coolant Systems

The turbocharger coolant system is designed to maintain the turbocharger’s operating temperature within specified limits to prevent thermal damage and ensure efficient performance. The Tur Coolant Drain Tube plays a role in this system by providing a means to periodically purge the coolant. This is particularly important in high-stress environments where the turbocharger is subjected to extreme temperatures and pressures.

The tube is engineered to withstand the pressures and temperatures inherent in the turbocharger coolant circuit. It is typically made from durable materials that resist corrosion and maintain integrity under high-stress conditions. The design of the tube also considers the flow dynamics to ensure that coolant drainage is efficient and complete, minimizing the risk of coolant residue that could lead to blockages or inefficiencies in the system.

Operational Benefits

By incorporating the Tur Coolant Drain Tube into the engine’s turbocharger coolant system, engineers and mechanics can perform routine maintenance with greater ease. The ability to drain coolant quickly and effectively allows for timely coolant changes, which is essential for maintaining the turbocharger’s efficiency and longevity. Additionally, it simplifies the process of flushing the system, which is necessary to remove any built-up contaminants that could impair coolant flow and heat exchange capabilities.

Conclusion

The Tur Coolant Drain Tube part 5340837, manufactured by Cummins, is a critical component in the maintenance and operational efficiency of turbocharged engine systems. Its design and features ensure effective coolant drainage, contributing to the prevention of engine overheating and the maintenance of optimal engine performance. Regular maintenance and proper installation are essential to maximize the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.