This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5342460 Pressure Sensing Tube is a component designed to facilitate accurate pressure readings within the systems of commercial trucks. Its role is integral to ensuring the truck operates efficiently and reliably. By providing precise pressure data, this tube supports various engine and system functions, contributing to the overall performance and longevity of the vehicle 2.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are conduits that allow for the transmission of pressure from one point to another within a system. They function by connecting pressure sensors to the areas where pressure needs to be measured, such as within engine compartments or fluid systems. These tubes are vital in automotive systems for monitoring and maintaining optimal pressure levels, which are crucial for the efficient operation of engines and other mechanical systems 3.

Purpose and Role in Truck Operation

The Cummins 5342460 Pressure Sensing Tube serves a specific purpose in the operation of commercial trucks by ensuring that pressure readings are accurately conveyed to the vehicle’s monitoring systems. This accurate data transmission plays a role in the truck’s engine management system by allowing for precise adjustments and operations based on real-time pressure conditions. Consequently, it contributes to the truck’s overall performance, efficiency, and reliability by enabling the system to make informed decisions based on accurate pressure data 4.

Key Features

The Cummins 5342460 Pressure Sensing Tube is characterized by several key features that enhance its functionality. It is constructed from durable materials that resist corrosion and wear, ensuring longevity and reliability. The design of the tube includes precise fittings and connections that facilitate secure and leak-free installation. Additionally, its unique characteristics, such as flexibility and resistance to high temperatures, allow it to perform effectively in the demanding environments typical of commercial truck operations 1.

Benefits

The incorporation of the Cummins 5342460 Pressure Sensing Tube into a truck’s system offers several benefits. It contributes to improved engine performance by ensuring that the engine management system receives accurate pressure readings, allowing for optimal operation. Enhanced fuel efficiency is another advantage, as precise pressure data enables the system to make adjustments that reduce fuel consumption. Furthermore, the reliability of pressure sensing applications is increased, leading to fewer system failures and reduced maintenance needs 2.

Installation and Integration

Proper installation and integration of the Cummins 5342460 Pressure Sensing Tube are crucial for its effective operation. Guidelines for installation include ensuring that the tube is correctly aligned and securely connected to avoid leaks or inaccurate readings. Compatibility with various truck models and engine types should be considered, as this ensures that the tube functions as intended within the specific system it is installed in. Careful attention to these factors during installation contributes to the tube’s performance and the overall efficiency of the truck 3.

Troubleshooting and Maintenance

Common issues with pressure sensing tubes may include leaks, blockages, or inaccurate readings. Troubleshooting these issues involves checking connections for tightness, inspecting the tube for signs of wear or damage, and ensuring that the sensor is functioning correctly. Maintenance practices for the Cummins 5342460 Pressure Sensing Tube include regular inspections for wear and damage, cleaning connections to prevent corrosion, and replacing the tube if significant wear is detected. These practices help ensure the tube’s optimal performance and longevity 4.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for commercial vehicles. The company’s reputation is built on its commitment to innovation, quality, and reliability. Cummins components, including the 5342460 Pressure Sensing Tube, are designed to meet the rigorous demands of commercial truck operations, contributing to the efficiency, performance, and reliability of these vehicles 1.

Compatibility with Cummins Engines

The Pressure Sensing Tube, identified by part number 5342460, is a critical component in the engine systems of various Cummins engines. This part is integral to the engine’s operation, ensuring accurate pressure readings which are essential for maintaining optimal performance and efficiency.

ISB6.7 G CM2180 B118

The ISB6.7 G CM2180 B118 engine is one of the models that utilize the Pressure Sensing Tube 5342460. This engine is known for its robust design and high performance, making it suitable for a variety of heavy-duty applications. The Pressure Sensing Tube in this engine is designed to withstand the high pressures and temperatures typical of such demanding environments 2.

Grouping of Engines

The Pressure Sensing Tube 5342460 is compatible with a range of Cummins engines, including but not limited to, the ISB6.7 G CM2180 B118. This part is engineered to fit seamlessly into the engine’s pressure sensing system, ensuring that it can accurately monitor and report pressure levels. The compatibility of this part across different engine models highlights its versatility and importance in maintaining engine health and performance 3.

Role in Engine Systems

The Pressure Sensing Tube 5342460 is a key component in the engine’s diagnostic and control systems, providing essential data that helps in the efficient operation of the engine. Its design and functionality are tailored to meet the specific needs of the engines it is intended for, ensuring reliable performance and longevity 4.

Integration with Exhaust System

In the exhaust system, the Pressure Sensing Tube is positioned to detect backpressure. This data is essential for the Engine Control Unit (ECU) to adjust fuel delivery and ignition timing, ensuring optimal performance and efficiency. By providing real-time pressure data, the tube helps in maintaining the correct exhaust flow, which is vital for reducing emissions and enhancing engine durability 1.

Function in Recirculation Systems

Within recirculation systems, such as Exhaust Gas Recirculation (EGR), the Pressure Sensing Tube plays a significant role. It monitors the pressure differentials across the EGR valve, allowing the ECU to regulate the flow of exhaust gases being recirculated back into the intake manifold. This regulation is key to reducing nitrogen oxides (NOx) emissions and improving combustion efficiency. The accurate pressure readings ensure that the EGR system operates within specified parameters, contributing to both performance and environmental compliance 2.

Overall System Contribution

The Pressure Sensing Tube’s ability to provide precise pressure data across these systems allows for fine-tuned control and optimization of engine operations. It ensures that both the exhaust and recirculation systems function harmoniously, leading to improved engine performance, reduced emissions, and increased reliability 3.

Conclusion

The Cummins 5342460 Pressure Sensing Tube is a vital component in the operation and maintenance of commercial trucks and Cummins engines. Its accurate pressure readings contribute to the efficient operation of engine systems, enhancing performance, fuel efficiency, and reliability. Proper installation, maintenance, and troubleshooting are essential to ensure the optimal performance of this part, ultimately contributing to the longevity and efficiency of the vehicles it serves 4.

-

Hilgers, M. (2023). Chassis and Axles. Springer Vieweg.

↩ ↩ ↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ ↩ ↩ ↩ -

Miedema, S. A., & Lu, Z. (2010). The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema.

↩ ↩ ↩ ↩ -

Schuetz, T. (2016). Aerodynamics of Road Vehicles: Fifth Edition. SAE International.

↩ ↩ ↩ ↩

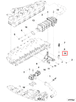

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.