This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

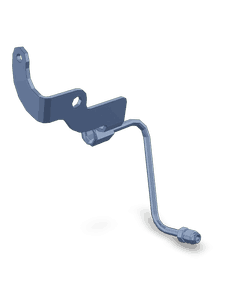

The 5344012 Pressure Sensing Tube, manufactured by Cummins, is a component designed for use in commercial truck operations. Cummins, a well-established name in the automotive industry, produces this part to enhance the functionality and efficiency of truck systems. This pressure sensing tube is integral to maintaining optimal performance and ensuring reliable operation of commercial vehicles.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are devices used to measure and transmit pressure data within various automotive systems. They function by detecting changes in pressure and converting these changes into electrical signals that can be interpreted by the vehicle’s onboard systems. These tubes are commonly employed in engine management, braking systems, and other areas where precise pressure monitoring is necessary 1.

Purpose of the 5344012 Pressure Sensing Tube

The 5344012 Pressure Sensing Tube plays a role in the operation of a truck by accurately measuring pressure levels within the system. It is integrated into the truck’s systems to collect data that is vital for maintaining optimal performance. This data helps in monitoring the condition of various components and ensuring that the truck operates within safe parameters.

Key Features

The 5344012 Pressure Sensing Tube is characterized by several key features. It is constructed from durable materials that ensure longevity and reliability under demanding conditions. The design incorporates precise engineering to ensure accurate pressure readings. Additionally, it features technological integrations that allow for seamless communication with the truck’s onboard systems, enhancing overall system performance.

Benefits

The 5344012 Pressure Sensing Tube offers several benefits. It contributes to improved system performance by providing accurate pressure data that enables better management of the truck’s systems. Enhanced diagnostic capabilities are another advantage, as the tube allows for real-time monitoring and quick identification of potential issues. Fleet operators may also experience cost savings due to the tube’s role in preventing system failures and reducing downtime.

Installation Process

Installing the 5344012 Pressure Sensing Tube involves several steps. First, ensure that the truck’s system is powered down and that all necessary safety precautions are in place. Next, locate the appropriate connection point within the system. Using the provided tools, connect the tube to the system, ensuring a secure fit. Finally, power up the system and verify that the tube is functioning correctly by checking the pressure readings on the diagnostic interface.

Troubleshooting Common Issues

Common issues with the 5344012 Pressure Sensing Tube may include inaccurate readings or failure to communicate with the onboard systems. To address these problems, first, check the connections to ensure they are secure and free from corrosion. If the issue persists, inspect the tube for any signs of damage. In some cases, recalibrating the tube or replacing it may be necessary to resolve the problem.

Maintenance Tips

Regular maintenance of the 5344012 Pressure Sensing Tube is important for ensuring its longevity and optimal performance. This includes periodic inspection of the connections and the tube itself for signs of wear or damage. Cleaning the tube and its connections can also help prevent issues related to corrosion or buildup. Additionally, following the manufacturer’s guidelines for maintenance intervals will help maintain the tube’s accuracy and reliability.

Role in Diagnostic Systems

The 5344012 Pressure Sensing Tube interacts with onboard diagnostic systems by providing real-time pressure data. This data is crucial for the diagnostic systems to assess the condition of various components and identify any anomalies. The tube’s accurate readings facilitate efficient troubleshooting, allowing for prompt resolution of issues and maintenance of the truck’s performance.

Impact on Fuel Efficiency

Accurate pressure readings from the 5344012 Pressure Sensing Tube can contribute to improved fuel efficiency in truck operations. By ensuring that the truck’s systems are operating within optimal parameters, the tube helps prevent inefficiencies that can lead to increased fuel consumption. This, in turn, can result in cost savings for fleet operators and a reduction in the truck’s environmental impact.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins is committed to innovation and excellence in the automotive industry. The company’s product range includes engines, filtration systems, and aftermarket parts, all designed to meet the demanding needs of commercial vehicle operators. Cummins’ dedication to quality and performance is evident in every product they offer, including the 5344012 Pressure Sensing Tube 2.

Pressure Sensing Tube (Part 5344012) Compatibility with Cummins Engines

The Pressure Sensing Tube, identified by part number 5344012, is a crucial component in the engine systems of various Cummins engines. This part is integral to the engine’s operation, ensuring accurate pressure readings and maintaining optimal performance.

ISF2.8 CM2220 F129

The ISF2.8 CM2220 F129 engine is one of the models that utilize the Pressure Sensing Tube 5344012. This engine is known for its reliability and efficiency, often used in heavy-duty applications. The Pressure Sensing Tube in this engine is designed to monitor and relay pressure data, which is essential for the engine’s control systems to adjust fuel delivery and other parameters dynamically.

Grouping of Engines

While the Pressure Sensing Tube 5344012 is specifically designed to fit the ISF2.8 CM2220 F129 engine, it is also compatible with other Cummins engines within the same family. These engines share similar design principles and operational requirements, making the Pressure Sensing Tube a versatile component across multiple models. Ensuring the correct fitment of this part is crucial for maintaining the engine’s performance and longevity.

Conclusion

The 5344012 Pressure Sensing Tube is a vital component in various engine systems, facilitating the accurate measurement and regulation of pressure within the system. This component is integral to the proper functioning of several key systems, including the Exhaust Gas Recirculation (EGR) system, the Turbocharger system, and the Manifold Absolute Pressure (MAP) sensor system.

In the EGR system, the Pressure Sensing Tube is responsible for monitoring the pressure differential between the intake manifold and the exhaust manifold. This data is vital for the EGR valve to operate correctly, ensuring that the appropriate amount of exhaust gas is recirculated back into the intake manifold. This recirculation helps in reducing nitrogen oxides (NOx) emissions, contributing to a cleaner and more efficient combustion process.

Within the Turbocharger system, the Pressure Sensing Tube plays a role in monitoring the boost pressure generated by the turbocharger. This information is used by the Engine Control Unit (ECU) to adjust the wastegate actuator, which controls the amount of exhaust gas bypassing the turbine. By maintaining optimal boost pressure, the turbocharger can deliver the necessary air volume to the engine, enhancing performance and efficiency.

In the context of the MAP sensor system, the Pressure Sensing Tube is used to measure the absolute pressure within the intake manifold. This pressure reading is essential for the ECU to calculate the air mass entering the engine, which is a critical parameter for fuel injection and ignition timing. Accurate pressure measurements ensure that the air-fuel mixture is optimal, leading to improved engine performance, fuel efficiency, and reduced emissions.

Overall, the 5344012 Pressure Sensing Tube is a vital component that ensures the precise operation of various engine systems by providing accurate pressure readings. Its integration into the EGR, Turbocharger, and MAP sensor systems underscores its importance in maintaining engine efficiency, performance, and compliance with emissions standards 3.

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.