5348911

Pressure Sensing Tube

Cummins®

IN STOCK

More than 10 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5348911 Pressure Sensing Tube is a component designed for use in commercial trucks. It serves a specific function within the engine management system, contributing to the overall performance and efficiency of the vehicle. Understanding its purpose and operation is key to maintaining and optimizing truck performance.

Basic Concepts of Pressure Sensing Tubes

Pressure sensing tubes are components used in automotive systems to monitor and regulate pressure within various parts of the engine. They work by transmitting pressure readings from one part of the system to a sensor or control unit, which then uses this data to adjust engine operations accordingly. These tubes are integral to ensuring that engine components operate within their optimal pressure ranges, thereby enhancing performance and efficiency 1.

Purpose of the Cummins 5348911 Pressure Sensing Tube

The Cummins 5348911 Pressure Sensing Tube plays a role in the engine management system by accurately transmitting pressure readings from specific points within the engine to the electronic control unit (ECU). This data allows the ECU to make precise adjustments to fuel injection, timing, and other parameters, ensuring the engine operates efficiently under varying conditions. Its integration within the system is designed to enhance overall engine performance and reliability 2.

Key Features

The Cummins 5348911 Pressure Sensing Tube is characterized by its robust design and the use of high-quality materials, ensuring durability and accurate pressure readings. Its design includes features that protect against corrosion and wear, enhancing its longevity. Additionally, the tube’s precise engineering allows for accurate pressure transmission, which is crucial for the ECU to make informed adjustments to engine operations 3.

Benefits

The use of the Cummins 5348911 Pressure Sensing Tube offers several advantages. It contributes to improved engine performance by enabling more accurate pressure readings, which the ECU uses to optimize fuel injection and timing. This results in enhanced fuel efficiency and reduced emissions. Furthermore, the reliable operation of the pressure sensing tube under various conditions ensures consistent engine performance, contributing to a smoother driving experience.

Installation and Integration

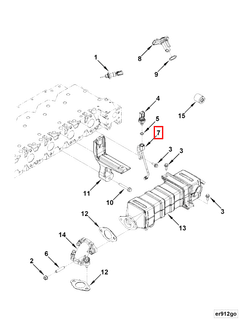

Installing the Cummins 5348911 Pressure Sensing Tube requires careful attention to ensure it is correctly positioned and connected within the engine management system. The process involves using specific tools to secure the tube in place and connect it to the appropriate sensors and control units. Integration with other components is crucial for the system to function correctly, highlighting the importance of following manufacturer guidelines during installation.

Troubleshooting and Maintenance

Common issues with the Cummins 5348911 Pressure Sensing Tube may include blockages or leaks, which can affect pressure readings and engine performance. Diagnostic procedures involve checking for physical damage, ensuring connections are secure, and verifying that the tube is free from obstructions. Regular maintenance, such as cleaning and inspecting the tube for wear, can help prevent issues and ensure optimal performance and longevity.

Performance Impact

The Cummins 5348911 Pressure Sensing Tube contributes to overall truck performance by enabling the engine management system to make precise adjustments based on accurate pressure readings. This results in improved engine efficiency, reduced emissions, and a more consistent driving experience. The tube’s role in maintaining optimal pressure levels within the engine is fundamental to achieving these performance benefits.

Technological Advancements

The Cummins 5348911 Pressure Sensing Tube incorporates several technological innovations that enhance its performance and reliability. These advancements include the use of corrosion-resistant materials, precise engineering for accurate pressure transmission, and design features that protect against wear and damage. Such innovations benefit commercial truck operations by ensuring the engine management system operates efficiently and reliably under a wide range of conditions.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and a commitment to quality, Cummins serves commercial, industrial, and automotive markets worldwide. The company’s product range includes engines, powertrain components, and aftermarket parts, all designed to meet the demanding requirements of modern transportation and power generation needs.

Pressure Sensing Tube 5348911 by Cummins

The Pressure Sensing Tube 5348911 by Cummins is a critical component designed to fit seamlessly into various engine configurations, ensuring precise pressure readings and maintaining engine efficiency. This part is integral to the operation of engines that rely on accurate pressure data for optimal performance.

ISB (Chrysler) Engines

In the ISB engines produced by Chrysler, the Pressure Sensing Tube 5348911 is meticulously engineered to integrate with the engine’s pressure monitoring systems. This tube plays a pivotal role in relaying pressure data from the engine’s critical areas, ensuring that the engine control unit (ECU) receives accurate information. This accuracy is vital for the ECU to make real-time adjustments, thereby enhancing engine performance and fuel efficiency.

The Pressure Sensing Tube 5348911 is designed to withstand the high temperatures and pressures typical of ISB engines, ensuring durability and reliability over extended periods of operation. Its precise fitment and robust construction make it an essential component for maintaining the integrity of the engine’s pressure monitoring systems.

Cummins Engines

For Cummins engines, the Pressure Sensing Tube 5348911 is engineered to fit into the engine’s pressure sensing circuits, providing critical data that the engine management system relies on. This part is designed to ensure that the engine operates within optimal parameters, contributing to overall engine health and longevity.

The tube’s design allows for easy installation and removal, facilitating maintenance and repairs. Its compatibility with various Cummins engine models ensures that it can be used across different engine configurations, providing a standardized solution for pressure sensing needs.

Grouping of Engines

The Pressure Sensing Tube 5348911 is versatile and fits into a range of engine groups, including but not limited to:

- Commercial and Industrial Engines: Designed for heavy-duty applications, this tube ensures that commercial and industrial engines maintain optimal performance under demanding conditions.

- Marine Engines: For marine applications, the tube’s resistance to corrosion and durability in harsh environments is crucial for maintaining engine reliability.

- Agricultural Engines: In agricultural settings, the tube’s ability to provide accurate pressure readings helps in optimizing engine performance for various farming operations.

By ensuring precise pressure readings, the Pressure Sensing Tube 5348911 by Cummins plays a vital role in the efficient and reliable operation of these engines. Its design and engineering make it a critical component for maintaining engine health and performance across various applications.

Role of Part 5348911 Pressure Sensing Tube in Engine Systems

The Part 5348911 Pressure Sensing Tube is an integral component in monitoring and maintaining the efficiency of various engine systems. Its primary function is to provide accurate pressure readings that are essential for the proper operation of the engine.

Integration with Exhaust System

In the exhaust system, the Pressure Sensing Tube is typically connected to the exhaust manifold or the turbocharger. It measures the backpressure in the exhaust, which is vital for the engine control unit (ECU) to adjust the fuel injection timing and air-fuel ratio. This ensures optimal combustion efficiency and reduces emissions. The data from the Pressure Sensing Tube helps in diagnosing potential issues such as clogged catalytic converters or restricted exhaust pipes, allowing for timely maintenance and repairs.

Role in Recirculation Systems

For recirculation systems, such as Exhaust Gas Recirculation (EGR) or Positive Crankcase Ventilation (PCV), the Pressure Sensing Tube plays a significant role. In the EGR system, it monitors the pressure differential across the EGR valve. This information is used by the ECU to control the amount of exhaust gas recirculated into the intake manifold, which helps in reducing nitrogen oxides (NOx) emissions.

In the PCV system, the Pressure Sensing Tube measures the pressure within the crankcase. This data assists the ECU in managing the ventilation rate, ensuring that blow-by gases are effectively removed from the crankcase. This prevents the buildup of harmful deposits and maintains engine cleanliness, contributing to longer engine life and improved performance.

Overall, the Pressure Sensing Tube is a key component in enhancing the functionality and efficiency of these engine systems.

Conclusion

The Cummins 5348911 Pressure Sensing Tube is a vital component in the engine management system of commercial trucks. Its role in providing accurate pressure readings ensures that the engine operates efficiently and reliably under various conditions. By enabling precise adjustments to fuel injection, timing, and other parameters, this part contributes to improved engine performance, reduced emissions, and a smoother driving experience. Its robust design, technological advancements, and compatibility with various engine configurations make it an essential component for maintaining engine health and performance across different applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.