This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

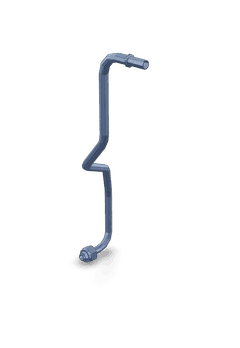

The 5367360 Compressor Water Outlet Tube, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive industry, is known for producing high-quality engine components. This particular part is significant within the context of heavy-duty truck engines, contributing to the efficient operation of the engine cooling system 1.

Basic Concepts

To understand the role of the 5367360 Compressor Water Outlet Tube, it is important to grasp some fundamental concepts related to compressor water outlet tubes. These tubes are integral to the engine cooling system, facilitating the movement of coolant from the compressor to other parts of the engine. They interact with various components, ensuring that the coolant is distributed effectively to maintain optimal engine temperature 2.

Role and Function

The 5367360 Compressor Water Outlet Tube serves a specific purpose in the operation of a truck. It directs the flow of coolant from the compressor to the engine cooling system. This function is vital for maintaining the engine’s temperature within safe operating limits, thereby supporting the overall efficiency and performance of the engine 3.

Key Features

The 5367360 Compressor Water Outlet Tube is characterized by several key features that enhance its performance and durability. These include its material construction, which is designed to withstand the high pressures and temperatures within the engine cooling system. The design specifications of the tube are tailored to ensure a precise fit and efficient coolant flow. Additionally, any unique attributes of the tube contribute to its reliability and longevity in demanding applications 4.

Benefits

Using the 5367360 Compressor Water Outlet Tube offers several benefits. It improves coolant circulation within the engine, which enhances the efficiency of the engine cooling system. This, in turn, can contribute to better overall engine performance and potentially extend the engine’s lifespan by maintaining optimal operating temperatures 5.

Installation and Compatibility

Proper installation of the 5367360 Compressor Water Outlet Tube is crucial for ensuring its effective function. Specific procedures should be followed to guarantee that the tube is correctly positioned and securely attached. Compatibility with Cummins engines and other relevant components is also an important consideration, ensuring that the tube integrates seamlessly into the engine system 6.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for the 5367360 Compressor Water Outlet Tube. Common issues such as leaks, blockages, or performance degradation should be addressed promptly to prevent more serious problems. Recommended maintenance practices include periodic inspections and replacements as needed to ensure the tube continues to function optimally 7.

Cummins Overview

Cummins Inc. is a prominent manufacturer in the automotive industry, with a long-standing reputation for producing high-quality engine components and systems. The company’s commitment to excellence is evident in its extensive range of products, which are designed to meet the demanding requirements of heavy-duty applications. Cummins’ history and dedication to innovation underscore its position as a leader in the field of engine manufacturing 8.

Cummins Compressor Water Outlet Tube 5367360 Compatibility

The Cummins Compressor Water Outlet Tube part number 5367360 is designed to fit seamlessly with the following engines:

- ISB5.9 CM2880 B127

- ISB5.9 CM2880 B127

This part is engineered to ensure optimal performance and reliability across these engine models. It is crucial for managing the flow of water within the engine’s cooling system, ensuring that the compressor operates within safe temperature parameters. The design of the water outlet tube is tailored to fit the specific architecture of these engines, providing a precise and secure connection that enhances the overall efficiency of the cooling system 9.

Role of Part 5367360 Compressor Water Outlet Tube in Compressor Coolant Arrangement

In the compressor coolant arrangement, the part 5367360 Compressor Water Outlet Tube serves as a vital conduit for the efficient circulation of coolant. This tube is strategically positioned to direct the flow of coolant from the compressor to other critical components within the system.

The Compressor Water Outlet Tube ensures that the coolant, after absorbing heat from the compressor, is effectively routed to the radiator or heat exchanger. This process is essential for maintaining optimal operating temperatures and preventing overheating of the compressor.

Additionally, the tube interacts with the coolant pump, which relies on a consistent and reliable flow of coolant to function correctly. The efficient operation of the pump is dependent on the precise routing provided by the Compressor Water Outlet Tube, ensuring that coolant is evenly distributed throughout the system.

Furthermore, the tube plays a role in the overall integrity of the coolant system by minimizing the risk of leaks and ensuring that coolant levels are maintained. This is particularly important in high-stress environments where the compressor is subject to varying loads and temperatures.

In summary, the Compressor Water Outlet Tube is integral to the compressor coolant arrangement, facilitating the smooth and efficient transfer of coolant to maintain system performance and reliability 10.

Conclusion

The 5367360 Compressor Water Outlet Tube is a critical component in the engine cooling system of heavy-duty truck engines. Its role in directing coolant flow, maintaining optimal engine temperature, and ensuring the efficient operation of the cooling system underscores its importance. Proper installation, regular maintenance, and understanding its function and compatibility are essential for maximizing the performance and longevity of this Cummins part.

-

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883565, ISB6.7 CM2350 B101.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩ -

Huzij, Robert, Spano, Angelo, Bennett, Sean. Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning, 2019.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883565, ISB6.7 CM2350 B101.

↩ -

Cummins Inc. Company Overview. Retrieved from Cummins Official Website.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 2883565, ISB6.7 CM2350 B101.

↩ -

Stiesch, Gunnar. Modeling Engine Spray and Combustion Processes. Springer Verlag, 2003.

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.