This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

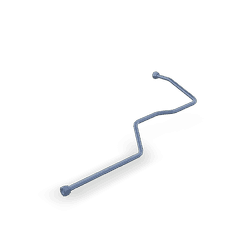

The Compressor Water Outlet Tube (part number 5524218), manufactured by Cummins, is a critical component in heavy-duty truck systems. Cummins, a renowned name in the automotive industry, specializes in diesel engines and related components. This tube is essential for the cooling system of heavy-duty trucks, ensuring efficient operation and longevity of the compressor 1.

Function and Operation

The Compressor Water Outlet Tube operates by directing coolant flow from the compressor to other parts of the cooling system. Its primary role is to maintain optimal compressor temperature through consistent coolant flow, which helps dissipate heat generated during operation. This contributes to the overall efficiency of the truck’s engine system 2.

Key Features

This Cummins part is designed with high-quality materials resistant to corrosion and high temperatures, ensuring durability and reliable operation in demanding environments. The tube’s design facilitates efficient coolant flow, minimizing the risk of blockages or leaks 3.

Role in Truck Operation

In heavy-duty truck operation, the Compressor Water Outlet Tube contributes to the efficient cooling of the compressor. This supports engine efficiency and longevity by ensuring the compressor operates within its optimal temperature range. Proper cooling is vital for maintaining the performance and reliability of the truck’s engine system 4.

Benefits

The Compressor Water Outlet Tube offers several advantages, including improved cooling efficiency, which reduces the risk of overheating. Enhanced compressor performance is another benefit, as consistent coolant flow ensures efficient operation. These factors contribute to the overall reliability and efficiency of the truck’s engine system 1.

Installation and Compatibility

When installing this part, it is important to follow manufacturer guidelines to ensure proper fit and function. Compatibility with various truck models should be verified to ensure optimal performance and integration within the truck’s cooling system. Careful attention to installation procedures helps maintain the efficiency and reliability of the cooling system 2.

Maintenance and Troubleshooting

Routine maintenance of the Compressor Water Outlet Tube includes regular inspections for signs of wear, corrosion, or leaks. Cleaning the tube and ensuring there are no obstructions in the coolant flow path is also recommended. Common issues may include leaks or reduced coolant flow, which can often be addressed by inspecting connections, replacing gaskets, or cleaning the tube 3.

Performance Impact

The Compressor Water Outlet Tube influences the overall performance of the truck’s engine and compressor system by ensuring efficient cooling. This contributes to fuel efficiency and operational reliability, as a well-cooled compressor is less likely to experience performance issues or failures. Consistent coolant flow is key to maintaining the compressor’s optimal operating temperature 4.

Safety Considerations

Regular inspections and timely replacements of the Compressor Water Outlet Tube are important safety measures. Ensuring the tube is in good condition helps prevent potential failures that could lead to overheating or compressor damage. Maintaining the integrity of the cooling system is vital for the safe and reliable operation of the truck 1.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for producing high-quality diesel engines and components. The company’s history is marked by innovation and a commitment to excellence, making it a trusted name in the manufacture of automotive parts. Cummins’ product range includes a variety of components designed to enhance the performance and reliability of vehicles 2.

Compatibility of Compressor Water Outlet Tube 5524218

The Compressor Water Outlet Tube (part number 5524218) is designed to fit seamlessly with several Cummins engine models. This part is integral to the cooling system, ensuring efficient water flow and temperature regulation within the engine.

ISL9 Engines

The ISL9 engine series benefits from the precise engineering of the 5524218 Compressor Water Outlet Tube. This part is specifically tailored to maintain optimal cooling performance, ensuring the engine operates within safe temperature limits.

CM2150 Engines

The CM2150 engine series incorporates the 5524218 Compressor Water Outlet Tube to enhance its cooling efficiency. This part is engineered to fit the unique design of the CM2150 engines, providing a reliable solution for water management and temperature control.

SN Engines

The SN engine series also utilizes the 5524218 Compressor Water Outlet Tube to support its cooling system. This part is designed to integrate smoothly with the SN engines, ensuring that water flow is optimized for efficient cooling.

Grouping of Engines

The Compressor Water Outlet Tube 5524218 is compatible with the ISL9, CM2150, and SN engine series. These engines, while differing in specific applications and performance characteristics, share a common requirement for effective cooling management. The 5524218 part number ensures that this critical function is met across these engine models, providing a reliable and consistent solution for water outlet management 3.

Role of Part 5524218 Compressor Water Outlet Tube in Engine Systems

The Compressor Water Outlet Tube, identified by part number 5524218, is a critical component in the thermal management system of an engine. It facilitates the efficient circulation of coolant from the compressor to other parts of the engine arrangement.

In the context of the compressor coolant system, this tube ensures that the coolant, after absorbing heat from the compressor, is effectively directed away to be cooled and then recirculated. This process is vital for maintaining optimal operating temperatures, which in turn enhances the performance and longevity of the compressor and associated engine components.

The tube interfaces with the compressor’s outlet port, where heated coolant is expelled. It then connects to the engine’s coolant circulation system, allowing the coolant to travel to the radiator or heat exchanger for cooling. This continuous cycle of coolant flow is integral to dissipating the heat generated during engine operation, thereby preventing overheating and potential damage to engine components.

Additionally, the design and placement of the Compressor Water Outlet Tube are tailored to accommodate the specific layout and requirements of the engine arrangement. This ensures that the coolant flow is unobstructed and that the tube can withstand the pressures and temperatures inherent in the engine’s operating environment.

Overall, the effective functioning of part 5524218 within the engine system underscores its importance in the thermal management strategy, contributing to the reliable and efficient operation of the engine 4.

Conclusion

The Compressor Water Outlet Tube (part number 5524218) is a vital component in the cooling system of heavy-duty trucks, ensuring efficient operation and longevity of the compressor. Its role in maintaining optimal compressor temperature through consistent coolant flow is crucial for the overall efficiency of the truck’s engine system. The design and materials used in this Cummins part enhance its performance and durability, making it a reliable choice for demanding environments. Regular maintenance and proper installation are key to ensuring the continued efficiency and reliability of the cooling system, contributing to the safe and efficient operation of the truck.

-

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ ↩ ↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ ↩ ↩ -

Nunney, M.J. (2007). Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann.

↩ ↩ ↩ -

Hilgers, M. (2023). Alternative Powertrains and Extensions to the Conventional Powertrain. Springer Nature.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.