This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

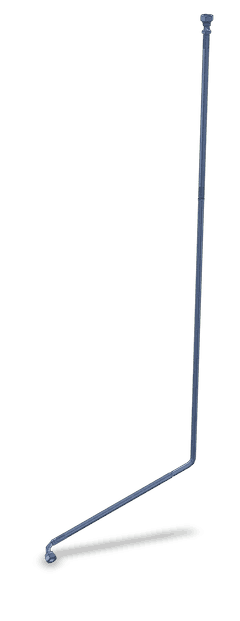

The Turbo Coolant Drain Tube, identified by Part #5544851, is a component manufactured by Cummins, a renowned leader in the production of diesel engines and related technologies. This part is integral to the cooling systems of heavy-duty truck engines, ensuring efficient operation and longevity of the engine components. Cummins is recognized for its commitment to quality and innovation in the automotive industry, making this Turbo Coolant Drain Tube a reliable choice for maintaining engine performance.

Basic Concepts

The Turbo Coolant Drain Tube operates on the fundamental principle of managing coolant flow within the engine’s cooling system. It facilitates the drainage of coolant from the turbocharger, which is crucial for maintaining optimal engine temperature. The tube interacts with the engine’s cooling system components, including the radiator and thermostat, to ensure a consistent coolant level and temperature. This interaction helps in dissipating heat generated by the turbocharger, thereby contributing to the overall efficiency of the engine cooling system 1.

Purpose and Function

The primary purpose of the Turbo Coolant Drain Tube is to aid in the maintenance of optimal engine temperature and performance. By allowing coolant to drain from the turbocharger, it prevents the buildup of excess coolant, which could lead to overheating. This function is vital for the turbocharger’s efficiency, as overheating can significantly reduce its performance and lifespan. The tube ensures that the coolant is circulated effectively, contributing to stable engine operation under various driving conditions 2.

Key Features

The Turbo Coolant Drain Tube is designed with several key features that enhance its functionality. It is typically made from durable materials that can withstand high temperatures and pressures within the engine compartment. The design includes precise fittings and connections to ensure a secure and leak-free installation. Additionally, the tube may feature anti-corrosion coatings to protect against the harsh chemicals present in coolant solutions, ensuring longevity and reliable performance.

Benefits

The advantages provided by the Turbo Coolant Drain Tube are significant. It contributes to improved engine efficiency by ensuring that the turbocharger operates within its optimal temperature range. This results in better fuel economy and reduced emissions. Furthermore, by preventing overheating, the tube helps in extending the lifespan of engine components, reducing the need for frequent repairs or replacements. The enhanced cooling also contributes to overall engine reliability, making it a valuable component in heavy-duty truck applications.

Installation and Compatibility

Proper installation of the Turbo Coolant Drain Tube is crucial for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure compatibility with the specific engine model. This may involve checking for the correct fitment and ensuring that all connections are secure and leak-free. Compatibility with various engine models is an important consideration, and it is advisable to consult the manufacturer’s specifications to ensure the tube is suitable for the intended application.

Maintenance and Troubleshooting

Routine maintenance of the Turbo Coolant Drain Tube is important to ensure its continued effective operation. This includes regular inspections for signs of wear, corrosion, or leaks. It is also important to ensure that the coolant level is maintained at the appropriate level and that the coolant solution is changed according to the manufacturer’s recommendations. Troubleshooting common issues, such as leaks or blockages, can often be resolved by inspecting the tube and connections, and making necessary repairs or replacements.

Common Failures and Solutions

Typical failure modes associated with the Turbo Coolant Drain Tube include leaks, corrosion, and blockages. Leaks can often be traced to loose connections or damaged fittings, which can be resolved by tightening or replacing the affected parts. Corrosion may be mitigated by using anti-corrosion coatings or replacing the tube with a more resistant material. Blockages can be cleared by flushing the cooling system and ensuring that the tube is free from debris. Regular maintenance and inspections can help in identifying and addressing these issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the automotive and heavy-duty truck industries. The company is committed to manufacturing high-quality components that meet the demanding requirements of modern engines, ensuring optimal performance and durability. Cummins’ dedication to excellence is reflected in its wide range of products, including the Turbo Coolant Drain Tube, which is designed to enhance engine efficiency and reliability.

Turbo Coolant Drain Tube Compatibility with Cummins Engines

The Turbo Coolant Drain Tube part number 5544851, manufactured by Cummins, is a critical component in the cooling system of certain engines. This part is designed to facilitate the drainage of coolant from the turbocharger, ensuring efficient operation and preventing potential damage due to coolant accumulation.

GTA38 G CMEICS G116C

The Turbo Coolant Drain Tube part number 5544851 is compatible with the GTA38 G CMEICS G116C engine. This part ensures that the coolant is effectively drained from the turbocharger, maintaining optimal performance and longevity of the engine. The integration of this component is crucial for the proper functioning of the cooling system, particularly in high-stress environments where turbochargers are prevalent.

Grouping of Compatible Engines

While the specific compatibility of the Turbo Coolant Drain Tube part number 5544851 with the GTA38 G CMEICS G116C engine has been highlighted, it is important to note that this part may also be suitable for other engines within the same family or series. Cummins engines are known for their robust design and engineering, and the Turbo Coolant Drain Tube is engineered to meet the stringent requirements of these systems.

The Turbo Coolant Drain Tube part number 5544851 is a testament to Cummins’ commitment to providing high-quality components that enhance engine performance and reliability. Its compatibility with the GTA38 G CMEICS G116C engine underscores the importance of using genuine parts for maintenance and repairs, ensuring that the engine operates at peak efficiency.

Role of Part 5544851 Turbo Coolant Drain Tube in Engine Systems

The part 5544851 Turbo Coolant Drain Tube is an essential component in the efficient operation of turbocharged engine systems. It is specifically designed to facilitate the drainage of coolant from the turbocharger, ensuring that the system remains free of excess coolant that could otherwise lead to performance issues or damage.

Integration with Plumbing Systems

In the context of engine plumbing, the Turbo Coolant Drain Tube plays a significant role. It is connected to the lower sections of the turbocharger where coolant may accumulate. The tube directs any excess coolant away from the turbocharger and into the engine’s coolant recovery system. This ensures that the coolant is properly circulated and does not cause overheating or other complications within the turbocharger housing.

Interaction with Turbocharger

The turbocharger relies on effective cooling to maintain optimal performance and longevity. The Turbo Coolant Drain Tube is integral to this process by providing a dedicated pathway for coolant to exit the turbocharger. This prevents coolant buildup, which can interfere with the turbocharger’s operation and lead to inefficiencies.

By ensuring that coolant is efficiently drained, the Turbo Coolant Drain Tube helps maintain the turbocharger’s thermal management. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions. Effective drainage contributes to stable turbocharger temperatures, enhancing overall engine reliability and performance.

Conclusion

The Turbo Coolant Drain Tube part number 5544851 is a critical component in the cooling systems of Cummins engines, particularly in turbocharged applications. Its role in managing coolant flow and preventing overheating is essential for maintaining engine efficiency and reliability. Proper installation, regular maintenance, and understanding of common failure modes are key to ensuring the effective operation of this part. Cummins’ commitment to quality and innovation is evident in the design and functionality of the Turbo Coolant Drain Tube, making it a valuable asset in heavy-duty truck engine systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.