C6204714250

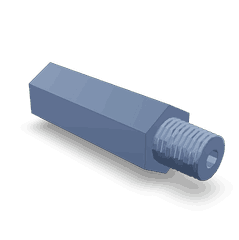

Tube Connector

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins C6204714250 Tube Connector is a specialized component designed for use in commercial truck systems. It serves as a link in various fluid systems, ensuring the efficient transfer of fluids such as fuel, coolant, and hydraulic fluid. This connector is engineered to meet the demanding requirements of heavy-duty applications, providing reliable performance and durability.

Basic Concepts of Tube Connectors

Tube connectors are components used in fluid systems to join tubes and pipes, facilitating the flow of liquids or gases. They are designed to create secure, leak-proof connections that can withstand pressure and vibration. Tube connectors operate by clamping onto the tubes, creating a tight seal that prevents fluid leakage and ensures consistent flow. They are vital in maintaining the integrity of fluid systems in vehicles and machinery.

Purpose of the Cummins C6204714250 Tube Connector

The Cummins C6204714250 Tube Connector plays a specific role in the operation of commercial trucks by connecting various fluid lines within the vehicle’s systems. It is commonly used in fuel systems, coolant systems, and hydraulic systems. By providing a secure connection point, it ensures that fluids are transferred efficiently and without leaks, contributing to the overall performance and reliability of the truck.

Key Features

This Cummins part is characterized by several key features that enhance its functionality. It is constructed from high-quality materials, such as stainless steel or durable polymers, which offer resistance to corrosion and wear. The design includes precision-machined surfaces to ensure a tight seal and robust clamping mechanism to maintain connection integrity under pressure. Additionally, it may feature unique characteristics such as integrated gaskets or O-rings to further enhance sealing capabilities.

Benefits

The C6204714250 Tube Connector offers several advantages. Its high-quality construction contributes to improved reliability and longevity, reducing the need for frequent replacements. The design allows for ease of installation, minimizing downtime during maintenance procedures. Furthermore, its durability ensures consistent performance in harsh operating conditions, making it suitable for heavy-duty applications.

Installation Process

Proper installation of this part involves several steps. Begin by ensuring that the tube ends are clean and free of debris. Align the connector with the tube and use the appropriate tools to clamp it securely in place. It is important to follow the manufacturer’s guidelines for torque specifications to ensure a proper seal without over-tightening, which could damage the connector or tube.

Common Issues and Troubleshooting

Common problems associated with tube connectors include leaks, loose connections, and corrosion. These issues can often be traced to improper installation, wear and tear, or exposure to harsh environments. Troubleshooting steps may involve re-tightening the connector, replacing worn components, or applying corrosion-resistant coatings to prevent further degradation.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and optimal performance of the C6204714250 Tube Connector. Inspect the connector periodically for signs of wear, corrosion, or leaks. Clean the connector and surrounding areas to remove any buildup that could affect performance. Additionally, ensure that all connections are tight and secure, following the manufacturer’s recommendations for maintenance intervals.

Safety Considerations

When working with tube connectors, it is important to observe several safety guidelines. Ensure that the vehicle is turned off and the system is depressurized before beginning any work. Use appropriate personal protective equipment, such as gloves and safety glasses, to protect against potential hazards. Follow all manufacturer instructions and safety guidelines to prevent accidents and ensure a safe working environment.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive and heavy-duty truck industry. The company is committed to innovation, quality, and customer satisfaction, providing reliable solutions for a wide range of applications.

Role of Part C6204714250 Tube Connector in Engine Systems

The C6204714250 Tube Connector is a component in the integration and functionality of various engine systems, particularly in the realms of plumbing and air-fuel control.

Plumbing Systems

In engine plumbing systems, the C6204714250 Tube Connector facilitates the secure and efficient transfer of fluids, such as coolant or oil, between different parts of the engine. It ensures that these fluids travel through the designated pathways without leaks, maintaining the engine’s thermal management and lubrication systems. The connector’s design allows for easy attachment and detachment, simplifying maintenance and repair processes. Additionally, it contributes to the overall reliability of the plumbing network by withstanding high pressures and temperatures commonly encountered in engine operations.

Air-Fuel Control Systems

Within the air-fuel control systems, the C6204714250 Tube Connector plays a significant role in managing the airflow and fuel delivery to the combustion chambers. It connects various components such as the intake manifold, fuel injectors, and exhaust systems, ensuring a seamless flow of air and fuel mixtures. This precise control is vital for optimizing combustion efficiency, reducing emissions, and enhancing overall engine performance. The connector’s robust construction ensures that it can handle the dynamic conditions within the air-fuel system, including rapid changes in pressure and temperature.

By integrating smoothly with these systems, the C6204714250 Tube Connector supports the engine’s operational integrity, contributing to both performance and durability.

Conclusion

The Cummins C6204714250 Tube Connector is a vital component in commercial truck systems, ensuring the efficient and reliable transfer of fluids. Its high-quality construction, ease of installation, and durability make it suitable for heavy-duty applications. Regular maintenance and proper installation are essential to maximize its performance and longevity. By understanding the role and benefits of this part, users can ensure the optimal operation of their vehicle’s fluid systems.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.