This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbine Housing 3518130 by Cummins is a critical component in the turbocharger system of commercial trucks. It optimizes turbocharger performance, enhancing engine efficiency and power output. Designed for heavy-duty applications, this part ensures robust performance under demanding conditions.

Basic Concepts of Turbine Housing

Turbine housings are essential for turbocharger functionality. They house the turbine wheel, which is spun by exhaust gases exiting the engine. This rotation drives the compressor wheel via a shared shaft, compressing intake air before it enters the engine cylinders. This process increases air density, allowing for more fuel to be burned and boosting engine power. The design and efficiency of the turbine housing directly influence turbocharger performance 1.

Purpose of Turbine Housing 3518130

The Turbine Housing 3518130 is engineered to enhance the operation of a truck’s turbocharger system. It efficiently channels exhaust gases to spin the turbine wheel, which drives the compressor wheel. This housing improves engine efficiency by ensuring optimal airflow and pressure within the turbocharger system. It maintains the balance between exhaust gas flow and compressor performance, contributing to increased power output and fuel efficiency.

Key Features

The Turbine Housing 3518130 features precise engineering for maximum efficiency, ensuring smooth exhaust gas flow. Constructed from high-quality materials, it offers enhanced durability and resistance to high temperatures and pressures. Its unique characteristics, such as the specific shape and size of the turbine inlet and outlet, are tailored to match Cummins turbochargers, ensuring seamless integration and performance.

Benefits

Utilizing the Turbine Housing 3518130 offers several benefits. It contributes to improved engine performance by ensuring efficient turbocharger operation. The housing’s design helps achieve higher boost pressures and better airflow, translating to increased power output. It also enhances fuel efficiency by optimizing the air-fuel mixture, allowing the engine to operate more effectively. The durable construction ensures long-term reliability and reduced maintenance needs, making it a cost-effective solution for commercial truck operators.

Installation and Integration

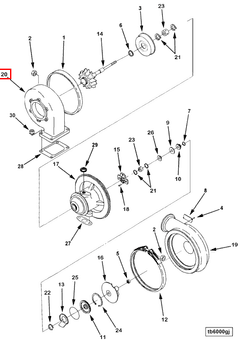

Installing the Turbine Housing 3518130 involves several steps to ensure proper integration into the truck’s turbocharger system. It is important to follow the manufacturer’s guidelines, which may include disconnecting the exhaust system, removing the old turbine housing, and fitting the new housing in its place. Careful attention should be paid to gaskets and seals to prevent leaks. Any necessary modifications or adjustments to the exhaust system should be made to accommodate the new housing, ensuring a secure and efficient fit.

Common Issues and Troubleshooting

Common issues with the Turbine Housing 3518130 may include leaks, reduced efficiency, or damage due to extreme conditions. Troubleshooting these problems involves inspecting the housing for cracks or deformities, checking the gaskets and seals for proper fit, and ensuring that the exhaust system is correctly aligned. If leaks are detected, replacing the gaskets or seals may resolve the issue. For reduced efficiency, cleaning or replacing the turbine wheel might be necessary. Regular inspections and maintenance can help identify and address these issues promptly.

Maintenance Tips

To ensure the Turbine Housing 3518130 operates at peak performance, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning the turbine wheel and inlet to remove any buildup, and checking the gaskets and seals for integrity. Following the manufacturer’s maintenance schedule will help identify any potential issues early and ensure the longevity of the component. Additionally, keeping the turbocharger system clean and free from contaminants will contribute to the overall efficiency and reliability of the turbine housing.

Performance Enhancements

Upgrading or modifying the Turbine Housing 3518130 can lead to performance enhancements. These may include increasing boost pressure by optimizing the turbine inlet and outlet design, or improving airflow through the housing. Such modifications can result in higher engine power output and better overall performance. It is important to ensure that any enhancements are compatible with the specific turbocharger model and are performed by qualified professionals to maintain safety and efficiency.

Cummins Overview

Cummins is a renowned manufacturer with a strong reputation in the industry for producing high-quality turbocharger components. With a history of innovation and commitment to excellence, Cummins continues to lead in the development of advanced turbocharger technologies. Their turbine housings, including the 3518130, are designed with precision and engineered to meet the demanding requirements of commercial truck applications, ensuring reliable performance and durability 2.

Compatibility

The Cummins Turbine Housing part number 3518130 is designed to fit seamlessly with various engine models. This part is engineered to ensure optimal performance and durability, making it a reliable choice for maintenance and repair needs.

QST30 CM552 Engines

The Turbine Housing part 3518130 is specifically designed to fit the QST30 CM552 engines. This part ensures that the turbine housing functions correctly within the engine’s framework, contributing to the overall efficiency and longevity of the engine.

Grouping of Engines

In the context of the QST30 CM552 engines, the Turbine Housing part 3518130 is essential for maintaining the structural integrity and operational efficiency of the engine. This part is engineered to withstand the rigors of engine operation, ensuring that the turbine housing remains a reliable component throughout the engine’s lifecycle.

Role in Engine Systems

Part 3518130 Turbine Housing is a critical component in the integration and operation of various engine systems, particularly when paired with aftermarket turbochargers and performance parts.

When installed in a turbocharger, the Turbine Housing directs the flow of exhaust gases, which spin the turbine wheel. This action is directly linked to the compressor wheel on the other side of the turbocharger, creating a pressurized air flow that enhances engine performance.

In a turbocharger kit, the Turbine Housing works in concert with other components such as the compressor housing, center housing, and the turbocharger itself. The efficiency of the Turbine Housing affects the overall performance of the kit, influencing factors such as boost pressure and response time.

For those utilizing performance parts, the Turbine Housing’s design and material can significantly impact the engine’s power output and thermal efficiency. A well-designed Turbine Housing can handle higher temperatures and pressures, allowing for greater tuning potential and overall engine performance.

Conclusion

In summary, the Turbine Housing 3518130 plays a significant role in the effective operation and performance enhancement of engine systems, especially when integrated with aftermarket turbochargers and performance parts. Its precise engineering, durable construction, and compatibility with various engine models make it a reliable and efficient component for commercial truck applications.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.