This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbine Housing 3518878 by Cummins is a component designed for use in turbocharger systems, specifically tailored for commercial trucks. This part is integral to the turbocharger’s operation, contributing to the overall efficiency and performance of the engine. Its application in commercial trucks underscores the importance of reliable and efficient turbocharger components in heavy-duty vehicles 1.

Basic Concepts of Turbine Housing

Turbine housings are fundamental components in turbocharger systems. They house the turbine wheel, which is spun by the engine’s exhaust gases. This spinning action drives the compressor wheel, which compresses the intake air before it enters the engine. The design and material of the turbine housing play a significant role in the efficiency of this process, directly impacting engine performance 2.

Purpose of Turbine Housing 3518878

The Turbine Housing 3518878 is designed to optimize the flow of exhaust gases over the turbine wheel. By efficiently directing these gases, it enhances the turbocharger’s ability to spin the compressor wheel at high speeds. This, in turn, increases the volume of air entering the engine, leading to improved combustion efficiency and power output 3.

Key Features

The Turbine Housing 3518878 features a precision-engineered design that maximizes airflow efficiency. It is constructed from high-quality materials to withstand the high temperatures and pressures of the exhaust system. Unique characteristics of this housing include its robust construction and design, which contribute to its performance and durability in demanding commercial truck applications 4.

Benefits

Utilizing the Turbine Housing 3518878 offers several advantages. It contributes to improved engine efficiency by optimizing turbocharger performance. This results in increased power output and better fuel economy. Additionally, its durable construction ensures long-term reliability, reducing the need for frequent replacements 5.

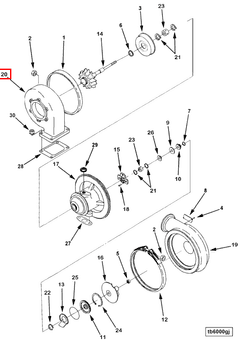

Installation Process

Installing the Turbine Housing 3518878 requires careful attention to ensure proper fitting and function. The process involves securing the housing to the engine’s exhaust system and connecting it to the turbocharger. Tools required may include wrenches and gaskets. It is important to follow manufacturer guidelines to ensure a secure and efficient installation 6.

Common Issues and Troubleshooting

Common issues with the Turbine Housing 3518878 may include leaks, cracks, or a decline in performance. These can often be traced to improper installation, wear and tear, or damage. Troubleshooting steps may involve inspecting the housing for visible damage, ensuring all connections are secure, and checking for leaks in the exhaust system 7.

Maintenance Tips

To prolong the life of the Turbine Housing 3518878, regular inspections are recommended. This includes checking for signs of wear, ensuring all connections are tight, and cleaning the housing to remove any buildup that could impede airflow. Adhering to recommended service intervals for inspection and maintenance can help maintain optimal performance 8.

Performance Enhancements

The Turbine Housing 3518878 can contribute to overall engine performance enhancements. By optimizing turbocharger efficiency, it can lead to improvements in fuel efficiency and power output. This makes it a valuable component for enhancing the performance of commercial trucks 9.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the industry, Cummins is committed to producing high-quality automotive components that meet the demanding requirements of commercial and industrial applications 10.

Understanding the Integration of Turbine Housing (Part 3518878) in Engine Systems

When enhancing engine performance through an aftermarket turbocharger, the turbine housing (part 3518878) assumes a significant role. This component is meticulously engineered to optimize the flow of exhaust gases, which are expelled from the engine’s cylinders.

The turbine housing encases the turbine wheel, which is spun by the high-velocity exhaust gases. This rotational energy is then transferred via the turbocharger’s shaft to the compressor wheel. The compressor wheel draws in ambient air, compresses it, and delivers it into the engine’s intake system at a higher pressure than atmospheric. This pressurized air allows for more fuel to be burned, thus increasing the engine’s power output 11.

In a turbocharger kit, the turbine housing is often one of the key parts that can be upgraded for performance gains. By improving the efficiency of the turbine housing, the overall effectiveness of the turbocharger is enhanced. This can lead to better throttle response, increased power, and improved fuel efficiency.

The integration of the turbine housing with other components such as the turbocharger and its associated parts is essential for the harmonious operation of the entire system. The design and material of the turbine housing can affect the temperature management within the turbocharger, influencing the longevity and reliability of the system.

For engineers and mechanics, understanding how part 3518878 fits within the broader context of the turbocharger and engine system is fundamental. It ensures that when modifications or upgrades are made, the performance enhancements are maximized while maintaining the integrity of the engine system 12.

Conclusion

The Turbine Housing 3518878 by Cummins is a critical component in the turbocharger systems of commercial trucks, designed to enhance engine efficiency and performance. Its precision engineering, durable construction, and role in optimizing turbocharger function make it a valuable asset for improving engine power output and fuel economy. Regular maintenance and proper installation are key to ensuring its longevity and effectiveness in demanding applications.

-

Singh, D. K. (2024). Dictionary of Mechanical Engineering. Springer Nature.

↩ -

Hilgers, M. (2022). The Drivers Cab. Springer Vieweg.

↩ -

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Company Overview.

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩ -

Cummins Inc. (n.d.). Service Manual (5579947).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.