This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

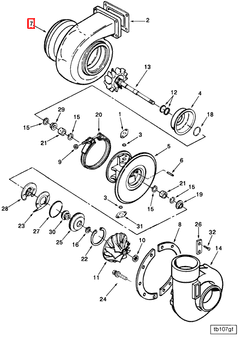

The Cummins 3519349 Turbine Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. It plays a role in optimizing engine performance by efficiently managing exhaust gases and contributing to improved airflow within the engine 1.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbocharger systems. They are responsible for directing exhaust gases to spin the turbine wheel, which in turn drives the compressor wheel to increase the airflow into the engine. This process enhances engine efficiency by allowing more air to be compressed into the combustion chamber, leading to better fuel combustion and increased power output 2.

Purpose of the 3519349 Turbine Housing

The 3519349 Turbine Housing is specifically engineered to fit within the turbocharger system of a truck’s engine. Its role involves channeling exhaust gases in a manner that maximizes the spin of the turbine wheel. This increased spin results in enhanced compressor wheel performance, leading to improved airflow and overall engine performance. The housing’s design contributes to a more efficient turbocharger operation, which is vital for the engine’s power and efficiency 3.

Key Features

The 3519349 Turbine Housing boasts several notable characteristics that enhance its functionality and durability. Its design is tailored to optimize the flow of exhaust gases, ensuring efficient turbine wheel spin. Constructed from high-quality materials, it is built to withstand the high temperatures and pressures associated with turbocharger operation. Additionally, its precise engineering ensures a secure fit within the turbocharger system, contributing to its overall performance and longevity 4.

Benefits

The advantages of the 3519349 Turbine Housing include increased engine efficiency, improved turbo response, and potential enhancements in fuel economy and power output. By optimizing the flow of exhaust gases and ensuring efficient turbocharger operation, this housing contributes to a more responsive and powerful engine performance. Furthermore, its design and construction help in maintaining these benefits over time, offering a reliable component for commercial truck engines 5.

Installation Process

Installing the 3519349 Turbine Housing requires attention to detail to ensure optimal performance and longevity. The process involves securely fitting the housing within the turbocharger system, ensuring all connections are tight and properly sealed. It is important to follow manufacturer guidelines for torque specifications and sealing procedures to prevent leaks and ensure efficient operation. Proper installation is key to maximizing the benefits of this component 6.

Common Issues and Troubleshooting

Turbine housings may encounter issues such as leaks or efficiency loss over time. Common problems include gasket failures or cracks in the housing, which can lead to exhaust gas leaks and reduced turbocharger efficiency. Troubleshooting these issues involves inspecting the housing for signs of damage or wear, checking gaskets for proper seating, and ensuring all connections are secure. Addressing these issues promptly can help maintain engine performance and prevent further damage 7.

Maintenance Tips

Maintaining the 3519349 Turbine Housing is crucial for prolonging its lifespan and ensuring optimal engine performance. Regular inspection routines should include checking for signs of wear, damage, or leaks. Cleaning the housing to remove any buildup of soot or debris is also important. Following recommended service intervals for inspection and maintenance can help identify potential issues early, allowing for timely repairs or replacements 8.

Compatibility and Application

The 3519349 Turbine Housing is designed for specific types of engines and truck models. It is important to consult compatibility information to ensure the housing is suitable for the intended application. Proper application ensures the housing will function as designed, contributing to efficient turbocharger operation and enhanced engine performance 9.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation in engine components. With a rich history of developing reliable and high-performance engine parts, Cummins continues to lead the industry with its advanced technologies and dedication to customer satisfaction. The company’s reputation for excellence is built on its ability to deliver components that enhance engine efficiency, reliability, and performance 10.

Role of 3519349 Turbine Housing in Engine Systems

The Turbine Housing, identified by part number 3519349, is an essential component in the operation of various turbocharger systems, including aftermarket turbochargers, EBM Performance Parts, EBM Turbochargers, Heat3B Turbochargers, and Performance Parts Turbocharger Kits.

Integration with Turbocharger Systems

When integrated into an aftermarket turbocharger setup, the Turbine Housing directs the flow of exhaust gases from the engine’s exhaust manifold. This housing is designed to optimize the velocity and pressure of these gases as they spin the turbine wheel, which in turn drives the compressor wheel to increase air intake and boost engine performance.

In EBM Performance Parts and EBM Turbocharger systems, the Turbine Housing plays a significant role in enhancing the efficiency of the turbocharger. By providing a precise pathway for exhaust gases, it ensures that the turbine wheel operates at optimal speeds, contributing to improved power output and responsiveness.

For Heat3B Turbocharger applications, the Turbine Housing is engineered to withstand high temperatures and pressures. Its design facilitates efficient heat management, allowing the turbocharger to maintain performance under extreme conditions without compromising durability.

Within Performance Parts Turbocharger Kits, the Turbine Housing is a key component that complements other high-performance parts. It works in tandem with the compressor housing, intercooler, and other elements to deliver a balanced and efficient turbocharging system. The housing’s design ensures that exhaust gases are effectively utilized to drive the turbine, resulting in enhanced engine performance and reliability.

Overall, the Turbine Housing (part 3519349) is integral to the functionality and performance of various turbocharger systems. Its role in managing exhaust gas flow and optimizing turbine operation is essential for achieving the desired performance enhancements in engine systems.

Conclusion

The 3519349 Turbine Housing by Cummins is a vital component in enhancing the performance and efficiency of turbocharger systems in commercial trucks. Its design and construction contribute to improved engine performance, reliability, and longevity. Proper installation, maintenance, and understanding of its role within the turbocharger system are essential for maximizing the benefits of this component.

-

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 4332649, ISB4.5 CM2350 B104.

↩ -

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 4332649, ISB4.5 CM2350 B104.

↩ -

Ed Sobey, A Field Guide to Automotive Technology, Chicago Review Press, 2009.

↩ -

Nicholas Goodnight and Kirk VanGelder, Automotive Braking Systems CDX Master Automotive Technician Series, Jones Bartlett Learning, 2019.

↩ -

Cummins Inc., Fault Code Troubleshooting Manual, Bulletin Number 4332649, ISB4.5 CM2350 B104.

↩ -

BT Fijalkowski, Automotive Mechatronics Operational and Practical Issues Volume 1, Springer, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.