This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

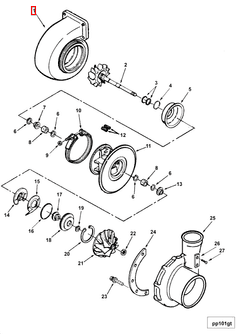

The Turbine Housing 3519351 by Cummins is a component designed for use in turbocharger systems, specifically tailored for commercial trucks. This housing plays a significant role in enhancing the performance and efficiency of the turbocharger, which in turn contributes to the overall engine performance of the vehicle 1.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbocharger systems. They encase the turbine wheel, which is spun by the exhaust gases exiting the engine. This spinning action drives the compressor wheel, which compresses the intake air before it enters the engine cylinders. The design and material of the turbine housing influence the efficiency and durability of the turbocharger system 2.

Purpose of the 3519351 Turbine Housing

The 3519351 Turbine Housing is engineered to optimize the operation of a truck’s turbocharger system. It aids in improving engine efficiency and power output by effectively managing the flow of exhaust gases. The housing’s design allows for efficient energy transfer from the exhaust gases to the turbine wheel, enhancing the compressor’s ability to deliver denser air to the engine 3.

Key Features

The 3519351 Turbine Housing boasts several key features that enhance its performance and durability. Its design is optimized for efficient airflow and minimal turbulence, which contributes to better turbocharger performance. The housing is constructed from high-quality materials that can withstand the high temperatures and pressures of the exhaust system. Additionally, it may feature unique characteristics such as advanced coatings or specific geometries that further improve its performance under demanding conditions 4.

Benefits

The use of the 3519351 Turbine Housing provides several benefits. It contributes to improved engine performance by ensuring efficient turbocharger operation. This results in increased power output and better throttle response. Additionally, the housing’s design and materials contribute to increased fuel efficiency and enhanced durability, allowing it to withstand the rigors of commercial truck operation 1.

Installation Process

Installing the 3519351 Turbine Housing requires careful attention to detail to ensure proper fitting and function. The process involves removing the old housing, inspecting the turbocharger and exhaust system for any damage, and then fitting the new housing. It is important to follow the manufacturer’s guidelines for torque specifications and sealing procedures to ensure a secure and leak-free installation 2.

Common Issues and Troubleshooting

Turbine housings can encounter issues such as leaks, cracks, and performance decline over time. Common causes include thermal stress, physical damage, and wear from high-temperature operation. Troubleshooting these issues involves inspecting the housing for visible damage, checking for leaks in the exhaust system, and assessing the overall condition of the turbocharger. Solutions may range from repairs to replacement, depending on the severity of the issue 3.

Maintenance Tips

To prolong the life of the 3519351 Turbine Housing, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning it to remove any buildup of soot or debris, and ensuring that all connections are secure and leak-free. Additionally, following the manufacturer’s recommended service intervals for the turbocharger system can help maintain optimal performance and durability 4.

Compatibility and Application

The 3519351 Turbine Housing is designed for specific types of engines and truck models. It is important to verify compatibility to ensure proper integration into the turbocharger system. The housing is engineered to meet the demands of commercial truck applications, providing reliable performance and durability in a variety of operating conditions 1.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s product range includes engines and components for on-highway, off-highway, and stationary applications, serving a wide array of industries. Cummins’ reputation in the commercial truck industry is built on its dedication to producing reliable, efficient, and durable products 2.

Turbine Housing Part 3519351 in Cummins Engines

The Turbine Housing part 3519351, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the proper functioning of the turbocharger system, ensuring efficient airflow and optimal engine performance.

N14 MECHANICAL Engines

In the N14 MECHANICAL engines, the Turbine Housing part 3519351 plays a pivotal role in the turbocharger’s operation. It houses the turbine wheel, which is spun by the exhaust gases, thereby driving the compressor to force more air into the engine. This design enhances the engine’s power output and fuel efficiency 3.

NH/NT 855 Engines

Similarly, in the NH/NT 855 engines, the Turbine Housing part 3519351 is essential for the turbocharger’s functionality. The housing is designed to withstand high temperatures and pressures, ensuring durability and longevity. Its precise fit and construction are critical for maintaining the turbocharger’s efficiency and reliability 4.

Compatibility and Installation

The Turbine Housing part 3519351 is engineered to fit seamlessly into the specified engine models. Cummins ensures that this part meets stringent quality standards, providing a reliable and durable solution for maintaining turbocharger performance. Proper installation of this component is crucial for the overall health and efficiency of the engine 1.

Role of Part 3519351 Turbine Housing in Engine Systems

The integration of part 3519351 Turbine Housing within various engine systems significantly enhances performance and efficiency. This component is engineered to work seamlessly with aftermarket turbochargers, ensuring optimal airflow and pressure management. When installed, the Turbine Housing interfaces directly with the turbocharger, allowing for precise control over exhaust gas flow, which is essential for maintaining the turbocharger’s efficiency and durability 2.

In conjunction with the Cam Follower Housing and Camshaft, the Turbine Housing plays a role in synchronizing the valve timing with the turbocharger’s operation. This synchronization ensures that the intake and exhaust valves open and close at the correct moments, maximizing the engine’s breathing capabilities and overall performance 3.

The Turbine Housing also interacts with the Connecting Rod and Piston assembly. By efficiently managing exhaust gases, it helps reduce backpressure, allowing the pistons to move more freely. This reduction in backpressure contributes to smoother engine operation and increased power output 4.

Furthermore, the Turbine Housing is a key component in the Cylinder Head setup. It ensures that the exhaust gases are expelled effectively, which is vital for maintaining consistent cylinder pressure and temperature. This, in turn, supports the cylinder head’s role in combustion efficiency and overall engine reliability 1.

When considering Injector Plumbing, the Turbine Housing aids in maintaining a stable exhaust flow, which is crucial for the accurate delivery of fuel. Stable exhaust flow ensures that the injectors operate within their designed parameters, leading to better fuel atomization and combustion 2.

For those utilizing a Campaign Kit or Turbocharger Kit, the Turbine Housing is an essential part that ensures all components work in harmony. It helps in fine-tuning the turbocharger’s performance, allowing for adjustments that can enhance both power and efficiency 3.

Lastly, the Turbine Housing’s role extends to the Dataplate, where it contributes to the accurate recording of engine performance metrics. By ensuring that the turbocharger operates within its designed parameters, the Turbine Housing helps in maintaining the integrity of the data recorded on the dataplate, which is vital for performance monitoring and diagnostics 4.

Conclusion

The 3519351 Turbine Housing by Cummins is a critical component in enhancing the performance and efficiency of turbocharger systems in commercial trucks. Its design, material, and integration with other engine components contribute to improved engine performance, increased power output, and better fuel efficiency. Proper installation, regular maintenance, and understanding its role within the engine system are essential for maximizing the benefits of this Cummins part.

-

Reif, Konrad. Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg, 2014.

↩ ↩ ↩ ↩ ↩ -

Martyr, A.J. Engine Testing: Theory and Practice: Third Edition. SAE International, 2007.

↩ ↩ ↩ ↩ ↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩ ↩ ↩ ↩ ↩ -

Schuetz, Thomas. Aerodynamics of Road Vehicles: Fifth Edition. SAE International, 2016.

↩ ↩ ↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.