This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3519409 Turbine Housing, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces a range of parts and systems that contribute to the efficiency and performance of engines. This part is significant within this context as it plays a role in the turbocharger system, which is vital for enhancing engine performance in heavy-duty applications 1.

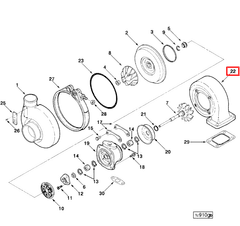

Basic Concepts of Turbine Housing

A Turbine Housing is a component of the turbocharger system. Its function is to house the turbine wheel, which spins at high speeds driven by the engine’s exhaust gases. This spinning action compresses the intake air, allowing more air to enter the engine’s combustion chamber. The increased airflow contributes to higher engine efficiency and power output. The design and construction of the Turbine Housing are critical to the turbocharger’s overall performance, as they affect the flow of exhaust gases and the efficiency of the turbine wheel 2.

Role of the 3519409 Turbine Housing in Truck Operation

This Cummins part is specifically designed to enhance the operation of heavy-duty trucks. It contributes to engine efficiency by optimizing the flow of exhaust gases, which in turn drives the turbine wheel more effectively. This results in improved air compression and a more efficient combustion process. The enhanced airflow facilitated by the 3519409 Turbine Housing can lead to increased power output and better overall engine performance in heavy-duty truck applications 3.

Key Features of the 3519409 Turbine Housing

The 3519409 Turbine Housing is constructed with materials and design features that ensure durability and performance. It is made from high-quality materials that can withstand the high temperatures and pressures of the turbocharger environment. The housing’s design includes features that promote efficient exhaust gas flow and reduce the risk of heat transfer to other engine components. These characteristics contribute to the overall reliability and performance of the turbocharger system.

Benefits of Using the 3519409 Turbine Housing

The use of the 3519409 Turbine Housing offers several advantages. It provides improved engine response due to the optimized airflow and efficient turbocharger operation. The durable construction of the housing contributes to increased longevity and reliability under demanding conditions. Additionally, the enhanced engine performance can lead to potential fuel efficiency gains, making it a valuable component for heavy-duty truck engines.

Installation and Integration

Proper installation of the 3519409 Turbine Housing is important for ensuring compatibility with various engine models and achieving optimal performance. It is designed to fit securely within the turbocharger system, with attention to correct fitting and sealing to prevent leaks and ensure efficient operation. Following manufacturer guidelines during installation is recommended to maintain the integrity of the turbocharger system and the overall engine performance.

Maintenance and Troubleshooting

Routine maintenance practices are important for ensuring the longevity and optimal performance of the 3519409 Turbine Housing. Regular inspections for signs of wear, damage, or leaks can help identify potential issues before they become significant problems. Common issues that may arise include turbine wheel imbalance or housing cracks, which can affect turbocharger efficiency. Addressing these issues promptly through repair or replacement can help maintain engine performance and reliability.

Performance Enhancements

The 3519409 Turbine Housing can contribute to performance enhancements in heavy-duty trucks. By optimizing the turbocharger system’s operation, it can lead to potential increases in horsepower and torque. These improvements can enhance the truck’s overall performance, making it more capable of handling demanding tasks and improving productivity in various applications.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industry, known for its wide range of engines, components, and systems. With a history of innovation and quality, Cummins has established a strong reputation for producing reliable and high-performance products. The company’s commitment to excellence is reflected in its product offerings, including the 3519409 Turbine Housing, which is designed to meet the demanding requirements of heavy-duty truck engines.

Turbine Housing Part 3519409 Compatibility with Cummins Engines

The Turbine Housing part 3519409, manufactured by Cummins, is a critical component in several of their engine models. This part is integral to the engine’s turbocharger system, ensuring efficient airflow and optimal performance. Here is a detailed look at its compatibility with various Cummins engines:

4B3.9 and 6B5.9 Engines

The 4B3.9 and 6B5.9 engines are part of Cummins’ B Series lineup, known for their robust design and reliability. The Turbine Housing part 3519409 fits seamlessly into these engines, providing a durable and efficient solution for turbocharger operation. This part is essential for maintaining the integrity of the turbocharger system, ensuring that the engine operates at peak performance levels.

QSB5.9 CM550 Engine

The QSB5.9 CM550 engine is another model where the Turbine Housing part 3519409 is a perfect fit. This engine is designed for heavy-duty applications, and the turbine housing plays a crucial role in managing the high-pressure airflow required for its operation. The part’s compatibility with the QSB5.9 CM550 ensures that the turbocharger can handle the demands of this powerful engine, contributing to its overall efficiency and longevity.

Grouping of Engines

The 4B3.9 and 6B5.9 engines share a common platform, making the Turbine Housing part 3519409 a versatile component for both models. This commonality allows for easier maintenance and repair, as the same part can be used across different engine variants. The QSB5.9 CM550, while part of a different series, also benefits from the same high-quality turbine housing, ensuring consistent performance and reliability across Cummins’ engine lineup.

Role of Part 3519409 Turbine Housing in Engine Systems

The Turbine Housing (Part 3519409) is a significant component in the operation of an Aftermarket Turbocharger, Turbocharger, and Turbocharger Kit. Its primary function is to house the turbine wheel, which is driven by the exhaust gases expelled from the engine.

When the exhaust gases flow through the turbine housing, they spin the turbine wheel. This wheel is connected to the compressor wheel via a shaft, creating a symbiotic relationship where the energy from the exhaust is used to compress the intake air.

In an Aftermarket Turbocharger, the Turbine Housing is often designed to optimize performance, providing better airflow and efficiency compared to the stock unit. This can result in increased power output and improved engine response.

In a standard Turbocharger setup, the Turbine Housing works in conjunction with the compressor housing to maintain the pressure ratio necessary for efficient turbo operation. The design of the turbine housing affects the turbocharger’s spool-up time and overall efficiency.

For a Turbocharger Kit, which typically includes various components to upgrade or replace the existing turbocharger system, the Turbine Housing plays a key role in ensuring that all parts work harmoniously. It must be compatible with the other components such as the wastegate, intercooler, and piping to achieve the desired performance gains.

Overall, the Turbine Housing is integral to the function and efficiency of turbocharger systems, directly influencing how effectively the turbocharger can enhance engine performance.

Conclusion

The 3519409 Turbine Housing by Cummins is a critical component for enhancing the performance and efficiency of heavy-duty truck engines. Its role in the turbocharger system ensures optimized airflow and efficient operation, contributing to increased power output, better engine response, and potential fuel efficiency gains. Proper installation, maintenance, and understanding of its compatibility with various Cummins engines are essential for maximizing the benefits of this part.

-

Drozdziel, Pawel. The Vehicle Diesel Engine Startup Process Operational and Environmental Aspects. Routledge, 2023.

↩ -

Fijalkowski, BT. Automotive Mechatronics Operational and Practical Issues Volume 1. Springer, 2011.

↩ -

Hick, Hannes, Klaus Kupper, and Helfried Sorger. Systems Engineering for Automotive Powertrain Development. Springer, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.