This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

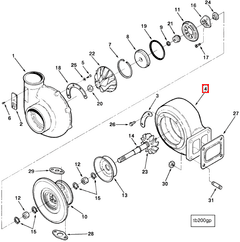

The Turbine Housing 3519901 by Cummins is a component designed to enhance the performance of turbocharger systems in commercial trucks. This housing plays a role in optimizing the turbocharger’s efficiency, which in turn contributes to improved engine performance. Understanding its function and significance can provide insights into how it aids in achieving better overall truck operation.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbocharger systems. They house the turbine wheel, which is driven by exhaust gases exiting the engine. The relationship between the turbine housing and the compressor housing is symbiotic; as the turbine wheel spins, it drives the compressor wheel, which increases the airflow into the engine. This process is fundamental to the operation of a turbocharger, as it allows for more efficient combustion and greater power output 1.

Purpose of the 3519901 Turbine Housing

The 3519901 Turbine Housing is specifically engineered to enhance the operation of a truck’s engine. It plays a role in increasing airflow by efficiently channeling exhaust gases to spin the turbine wheel. This increased airflow contributes to engine efficiency by allowing for more complete combustion of the air-fuel mixture, which can lead to improved engine performance 2.

Key Features

The 3519901 Turbine Housing is constructed with precision engineering and high-quality materials to ensure durability and performance. Its design includes features that enhance the flow of exhaust gases, optimizing the turbine’s efficiency. The materials used are selected for their ability to withstand high temperatures and pressures, ensuring longevity and reliability in demanding commercial truck applications 3.

Benefits

The advantages of the 3519901 Turbine Housing include improved engine response, increased power output, and enhanced fuel efficiency. These benefits contribute to overall truck performance by allowing the engine to operate more efficiently under a variety of conditions. The housing’s design and construction play a role in achieving these performance enhancements 4.

Installation and Integration

Proper installation of the 3519901 Turbine Housing is important for ensuring compatibility with the truck’s turbocharger system. It is designed to integrate seamlessly with other components, but careful attention to manufacturer guidelines is recommended to achieve optimal performance. Adjustments may be necessary to ensure a proper fit and function within the system.

Performance Optimization

To optimize the performance of the 3519901 Turbine Housing, considerations such as tuning and maintenance practices are important. Regular inspections and maintenance can help ensure the housing continues to operate efficiently. Additionally, upgrades or modifications to the turbocharger system may further enhance performance, depending on the specific requirements of the application.

Troubleshooting and Maintenance

Common issues with turbine housings can include leaks, cracks, or inefficient exhaust gas flow. Diagnostic procedures for identifying problems may involve visual inspections, pressure tests, or performance analysis. Maintenance routines, such as regular cleaning and inspection, can help ensure the longevity and reliability of the 3519901 Turbine Housing.

Cummins Corporation

Cummins Corporation is a well-established manufacturer in the commercial truck industry, known for its commitment to innovation and quality. The company offers a wide range of products, including turbocharger components, and has a reputation for producing reliable and high-performance parts. Cummins’ dedication to advancing technology in the automotive sector underscores its position as a leader in the industry.

Turbine Housing (Part 3519901) in Cummins Engines

The Turbine Housing (part 3519901) is a critical component in several Cummins engines, ensuring efficient operation and performance. This part is integral to the engine’s turbocharger system, where it houses the turbine wheel and facilitates the flow of exhaust gases to drive the turbine, which in turn powers the compressor.

L10 MECHANICAL Engines

In the L10 MECHANICAL engines, the Turbine Housing (part 3519901) is designed to withstand the high temperatures and pressures generated by the exhaust gases. This housing is engineered to provide a precise fit and alignment with the turbocharger’s turbine wheel, ensuring optimal performance and longevity. The design of the Turbine Housing in these engines is crucial for maintaining the structural integrity and efficiency of the turbocharger system.

Grouping of Engines

The Turbine Housing (part 3519901) is also compatible with other Cummins engines within the same mechanical and performance specifications. These engines share similar design principles and operational requirements, ensuring that the turbine housing fits seamlessly and functions effectively across different models. The commonality in design allows for easier maintenance and repair, as well as the potential for interchangeable parts within the group.

Role of Part 3519901 Turbine Housing in Engine Systems

When integrating Part 3519901 Turbine Housing into an engine system, it is essential to understand its interaction with various components to ensure optimal performance and efficiency.

Interaction with Aftermarket Turbocharger

The Turbine Housing is a fundamental component when installing an aftermarket turbocharger. It houses the turbine wheel, which is driven by the exhaust gases. The design and size of the Turbine Housing significantly influence the turbocharger’s efficiency and the overall boost pressure. A well-matched Turbine Housing ensures that the turbocharger operates within its designed parameters, enhancing the engine’s power output and responsiveness.

Integration with Turbocharger Kit

In a turbocharger kit, the Turbine Housing works in conjunction with the compressor housing, center housing, and other parts to create a balanced system. The Turbine Housing’s design affects the velocity and pressure of the exhaust gases, which in turn impacts the speed of the turbine wheel. This interaction is vital for maintaining the correct air-fuel ratio and ensuring that the turbocharger delivers consistent performance across a range of engine speeds.

Performance Enhancement

Upgrading to a high-performance Turbine Housing can significantly enhance the engine’s performance. A larger Turbine Housing allows for increased exhaust flow, which can result in higher boost levels and improved throttle response. Conversely, a smaller Turbine Housing can provide quicker spool-up times, making the turbocharger more responsive at lower RPMs. The choice of Turbine Housing should align with the specific performance goals of the engine build, whether it be increased power, improved drivability, or a balance of both.

Compatibility with Engine Systems

When fitting Part 3519901 Turbine Housing, it is important to consider its compatibility with the existing engine components. The Turbine Housing must be properly matched to the turbocharger’s compressor side to avoid issues such as lag or over-boosting. Additionally, it should be compatible with the engine’s exhaust system to ensure smooth and efficient exhaust gas flow. Proper sealing and mounting of the Turbine Housing are also essential to prevent leaks and maintain system integrity.

Conclusion

Understanding the role of Part 3519901 Turbine Housing in the context of aftermarket turbochargers, turbocharger kits, and overall engine performance is key to achieving the desired outcomes in any engine modification project.

-

Reif, Konrad. Brakes Brake Control and Driver Assistance Systems Function Regulation and Components. Springer, 2014.

↩ -

Bonnick, Allan. A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier, 2004.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.