This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbine Housing 3521264 by Cummins is a component designed for use in turbocharger systems, specifically tailored for heavy-duty truck applications. This part is integral to the turbocharger’s operation, enhancing engine performance by optimizing the flow of exhaust gases. Its application in heavy-duty trucks underscores the importance of robust and efficient turbocharger components in demanding environments 1.

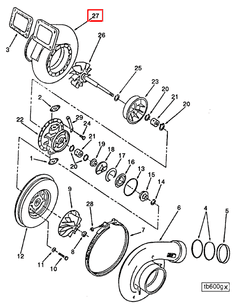

Basic Concepts of Turbine Housing

Turbine housings are fundamental components in turbocharger systems. They encase the turbine wheel, which is spun by exhaust gases exiting the engine. The design and efficiency of the turbine housing play a significant role in the turbocharger’s ability to compress intake air, thereby increasing engine power and efficiency. The housing’s role is to direct exhaust gases in a manner that maximizes turbine wheel speed, which in turn drives the compressor wheel to increase air intake 2.

Purpose of Turbine Housing 3521264

The Turbine Housing 3521264 is designed to enhance the operation of a truck’s engine within the turbocharger system. It facilitates the efficient conversion of exhaust gas energy into mechanical energy, which is used to spin the turbine wheel. This action drives the compressor wheel, increasing the volume and pressure of air entering the engine. The housing’s design contributes to improved engine responsiveness and power output, crucial for heavy-duty truck performance 3.

Key Features

The Turbine Housing 3521264 boasts several key features that enhance its performance and durability. Constructed from high-quality materials, it is designed to withstand the high temperatures and pressures of exhaust gases. Its engineering specifications include precise dimensions and a robust design that ensures efficient gas flow and minimal heat transfer to other engine components. These features contribute to the housing’s reliability and effectiveness in demanding applications 4.

Benefits

The benefits of the Turbine Housing 3521264 include improved engine efficiency, increased power output, and enhanced reliability. By optimizing the flow of exhaust gases, it allows for more efficient turbocharger operation, leading to better engine performance. The increased power output is particularly beneficial for heavy-duty trucks, where engine power is a critical factor. Additionally, the housing’s durable construction ensures long-term reliability, reducing the need for frequent replacements 5.

Installation Process

Installing the Turbine Housing 3521264 requires careful attention to detail to ensure proper fitment and function. The process involves preparing the turbocharger and engine components, aligning the housing with the turbine wheel, and securing it in place using the appropriate tools. Proper alignment and secure fastening are crucial to prevent leaks and ensure efficient operation. Following manufacturer guidelines during installation is recommended to achieve optimal performance 6.

Common Issues and Troubleshooting

Common issues associated with turbine housings include leaks, cracks, and performance decline over time. Leaks can occur at the housing’s seals or connections, leading to reduced turbocharger efficiency. Cracks may develop due to thermal stress or physical damage. Performance decline can result from deposits or wear within the housing. Troubleshooting these issues involves inspecting the housing for visible damage, checking for leaks, and assessing the overall condition of the turbocharger system. Solutions may include repairs, cleaning, or replacement of the housing 7.

Maintenance Tips

To prolong the lifespan of the Turbine Housing 3521264, regular maintenance is recommended. This includes inspecting the housing for signs of wear or damage, cleaning it to remove deposits that could affect performance, and ensuring all connections are secure and leak-free. Following the manufacturer’s maintenance schedule and guidelines can help maintain the housing’s efficiency and reliability over time 8.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s product range includes engines, powertrains, and related components, designed to meet the demanding requirements of various applications.

Cummins Turbine Housing Part 3521264 Compatibility

The Cummins Turbine Housing part number 3521264 is meticulously engineered to fit seamlessly within the K19 and K38 engine families. This precision-crafted component is integral to the engine’s operation, ensuring optimal performance and longevity.

K19 Engine Family

The K19 engine series is renowned for its robust design and reliability, often utilized in heavy-duty applications. The Turbine Housing part 3521264 is specifically designed to integrate with the K19 engines, providing a secure fit that withstands the rigors of demanding operational environments. Its compatibility with the K19 series ensures that the turbine housing maintains the integrity of the engine’s airflow and pressure systems, crucial for efficient operation.

K38 Engine Family

Similarly, the K38 engine family benefits from the precision engineering of the Turbine Housing part 3521264. This part is tailored to fit the unique specifications of the K38 engines, ensuring that the turbine housing aligns perfectly with the engine’s design. The seamless integration of this component with the K38 engines is vital for maintaining the engine’s performance and durability, particularly in applications where reliability is paramount.

By ensuring a precise fit with both the K19 and K38 engine families, the Cummins Turbine Housing part 3521264 underscores Cummins’ commitment to quality and compatibility, providing engine operators with a reliable and efficient solution.

Role of Part 3521264 Turbine Housing in Engine Systems

The Turbine Housing, identified by part number 3521264, is an integral component in the functionality of aftermarket turbochargers and turbocharger kits. When integrated into these systems, the Turbine Housing works in concert with several key components to enhance engine performance.

Integration with Aftermarket Turbocharger

In an aftermarket turbocharger setup, the Turbine Housing is responsible for directing the flow of exhaust gases. These gases spin the turbine wheel, which is connected to the compressor wheel via a shaft. The efficiency of this process directly influences the compressor’s ability to force more air into the engine’s cylinders, thereby increasing power output. The design of the Turbine Housing affects the velocity and pressure of the exhaust gases, which are vital for optimal turbocharger performance.

Interaction with Cylinder Head

The cylinder head plays a significant role in the engine’s combustion process. It houses the intake and exhaust valves, which open and close to allow air and fuel into the cylinders and expel exhaust gases. The Turbine Housing indirectly impacts the cylinder head by influencing the exhaust gas flow. Efficient exhaust gas evacuation allows for better intake air flow, which is essential for maintaining proper air-fuel ratios and maximizing engine efficiency.

Contribution to Performance Parts

When considering performance parts, the Turbine Housing is a key element. It is often modified or upgraded in performance turbocharger kits to improve exhaust gas scavenging. This enhancement leads to increased turbocharger responsiveness and overall engine performance. The housing’s design can be tailored to specific engine requirements, allowing for fine-tuning of the turbocharger’s operation to match the engine’s performance characteristics.

Role in Turbocharger Kit

In a comprehensive turbocharger kit, the Turbine Housing is one of the primary components that determine the kit’s effectiveness. It works alongside the compressor housing, turbine wheel, and compressor wheel to create a balanced system. The housing’s design must complement the other components to ensure that the turbocharger operates within its optimal range, providing the desired boost pressure without causing undue stress on the engine.

Summary of Component Interaction

The Turbine Housing (part 3521264) is a vital link in the chain of components that make up a turbocharger system. Its role in directing exhaust gases not only affects the turbocharger’s efficiency but also has a cascading effect on the engine’s overall performance. By working in harmony with the cylinder head and other performance parts, the Turbine Housing contributes to the enhanced power and efficiency that turbochargers are known for.

Conclusion

The Turbine Housing 3521264 by Cummins is a critical component in the turbocharger system, designed to optimize engine performance in heavy-duty truck applications. Its role in directing exhaust gases and enhancing turbocharger efficiency contributes to improved engine power, efficiency, and reliability. Proper installation, maintenance, and understanding of its interaction with other engine components are essential for maximizing the benefits of this part.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Synthesis Lectures on Advances in Automotive Technology, Amir Khajepour, Springer, 2023

↩ -

Simulation and Optimization of Internal Combustion Engines, Zhiyu Han, SAE International, 2022

↩ -

Systems Engineering for Automotive Powertrain Development, Hannes Hick, Klaus Kupper, and Helfried Sorger, Springer, 2021

↩ -

QSB4.5 CM2350 B122, Bulletin Number 4388769, Owners Manual

↩ -

Ibid.

↩ -

Ibid.

↩ -

Ibid.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.