This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

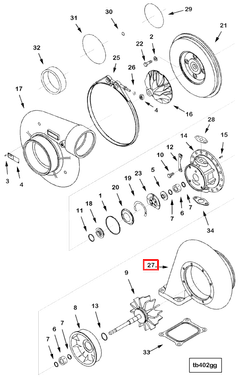

The Cummins 3521265 Turbine Housing is a component designed for use in the turbocharger systems of heavy-duty trucks. Its purpose is to enhance the efficiency and performance of the engine by optimizing the flow of exhaust gases. This part is significant in the operation of heavy-duty trucks as it contributes to the overall power output and fuel efficiency of the vehicle.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel to increase the air intake into the engine. This process contributes to engine performance by allowing more air to be compressed into the combustion chamber, resulting in more efficient fuel combustion and increased power output 1.

Role of the 3521265 Turbine Housing in Truck Operation

The 3521265 Turbine Housing plays a specific role in the turbocharger system of a truck by optimizing the flow of exhaust gases. This optimization affects air intake by ensuring that the turbine wheel spins efficiently, which drives the compressor wheel to increase the volume of air entering the engine. This increased air intake enhances engine efficiency by allowing for more complete combustion of fuel, which can lead to improved power output and fuel economy 2.

Key Features of the 3521265 Turbine Housing

The design and construction of the 3521265 Turbine Housing include features that enhance its performance. It is made from durable materials that provide structural integrity and resistance to the high temperatures and pressures of exhaust gases. The housing is engineered to ensure precise exhaust gas flow, which is crucial for the efficient operation of the turbocharger. Additionally, its design may include features that reduce noise and vibration, contributing to a smoother operation of the truck 3.

Benefits of Using the 3521265 Turbine Housing

The advantages provided by the 3521265 Turbine Housing include improved engine performance, durability, and efficiency. By optimizing the flow of exhaust gases, it contributes to increased power output and better fuel economy. Its durable construction ensures longevity, reducing the need for frequent replacements. Furthermore, the efficient design of the housing can lead to reduced emissions, aligning with environmental standards 4.

Installation Considerations

When installing the 3521265 Turbine Housing, it is important to follow guidelines and best practices to ensure proper fit and function. Compatibility with various truck models should be verified to ensure optimal performance. Necessary precautions include checking for any damage to the housing before installation and ensuring that all connections are secure to prevent leaks or inefficiencies in the turbocharger system.

Maintenance and Troubleshooting

To maintain the 3521265 Turbine Housing, regular inspections for signs of wear or damage are recommended. Common issues that may arise include leaks in the housing or reduced efficiency due to buildup of exhaust deposits. Troubleshooting tips include cleaning the housing to remove any deposits and checking for proper alignment and secure connections. Regular maintenance can ensure optimal performance and longevity of the turbocharger system.

Performance Impact

The 3521265 Turbine Housing influences the overall performance of the truck by contributing to fuel efficiency, power output, and reliability. Its role in the turbocharger system allows for more efficient combustion, which can lead to increased power and better fuel economy. Additionally, the durable construction and efficient design of the housing contribute to the reliability and longevity of the truck’s engine.

Cummins: A Brief Overview

Cummins Inc. is a well-established company in the automotive industry, known for its high-quality automotive components. With a history of innovation and commitment to excellence, Cummins has built a reputation for producing reliable and efficient parts for engines and turbochargers. The company’s dedication to quality is evident in its products, including the 3521265 Turbine Housing, which is designed to meet the demanding requirements of heavy-duty truck applications.

Turbine Housing (Part 3521265) Compatibility with Cummins Engines

The Turbine Housing, identified by part number 3521265, is a critical component in Cummins engines, ensuring efficient operation and performance. This part is designed to fit seamlessly within specific Cummins engine models, providing a robust housing for the turbine.

K19 Engine

The K19 engine is one of the models that utilizes the Turbine Housing part 3521265. This part ensures that the turbine operates within a well-contained environment, contributing to the engine’s overall efficiency and longevity.

K38 and K50 Engines

Similarly, the K38 and K50 engines also incorporate the Turbine Housing part 3521265. This part is integral to these engines, providing a secure and efficient housing for the turbine, which is essential for maintaining optimal engine performance.

Grouping of Engines

The K19, K38, and K50 engines share a commonality in their use of the Turbine Housing part 3521265. This part is designed to fit these engines precisely, ensuring that the turbine operates efficiently and reliably. The compatibility of this part across these engines highlights its versatility and importance in maintaining engine performance.

Role of Part 3521265 Turbine Housing in Engine Systems

The Turbine Housing, identified by part number 3521265, is an integral component in various engine systems, particularly when integrated with aftermarket turbochargers and performance parts.

When paired with an Aftermarket Turbocharger, the Turbine Housing plays a significant role in optimizing the turbocharger’s efficiency. It directs the flow of exhaust gases, which spin the turbine wheel, thereby driving the compressor wheel to increase air intake. This setup is essential for enhancing engine performance and power output.

In the context of an HX80 Turbocharger, the Turbine Housing is designed to handle high exhaust flow rates. It ensures that the turbine wheel receives a consistent and powerful stream of exhaust gases, which is vital for maintaining the turbocharger’s operational integrity under high-stress conditions.

For the Turbo T18A KV12 configuration, the Turbine Housing is tailored to fit the specific dimensions and requirements of this turbocharger model. It aids in achieving the desired turbo boost levels by efficiently channeling exhaust gases, which is fundamental for the turbocharger’s performance.

In a Turbocharger Kit, the Turbine Housing is often included as a key component. It works in conjunction with other parts of the kit to ensure that the turbocharger system is assembled correctly and functions as intended. This integration is important for the overall effectiveness of the turbocharger system in enhancing engine performance.

Lastly, when considering Performance Parts, the Turbine Housing is a component that significantly influences the turbocharger’s ability to deliver increased power. Its design and material are often upgraded in performance setups to withstand higher temperatures and pressures, contributing to the turbocharger’s durability and efficiency.

Conclusion

The Cummins 3521265 Turbine Housing is a vital component in the turbocharger systems of heavy-duty trucks, contributing to enhanced engine performance, fuel efficiency, and reliability. Its design and construction are tailored to optimize the flow of exhaust gases, ensuring efficient operation of the turbocharger. Regular maintenance and proper installation are key to maximizing the benefits of this part, which is compatible with various Cummins engine models including the K19, K38, and K50. The Turbine Housing’s role in aftermarket turbochargers and performance parts further underscores its importance in achieving optimal engine performance.

-

Genta, G., & Morello, L. (2019). The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer.

↩ -

Carroll, D. R. (2020). Energy Efficiency of Vehicles. SAE International.

↩ -

Kershaw, J. F. (2023). SAE International’s Dictionary for Automotive Engineers. SAE International.

↩ -

Van Gelder, K. T. (2018). Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.