This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

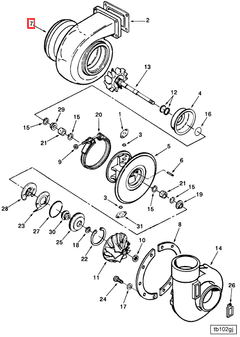

The Turbine Housing 3521838 by Cummins is a component designed for use in turbocharger systems, specifically tailored for commercial trucks. This part is integral to the turbocharger’s operation, enhancing engine performance and efficiency. Its application in commercial trucks underscores the importance of reliable and efficient turbocharger components in heavy-duty vehicles 2.

Basic Concepts of Turbine Housing

A turbine housing is a component of a turbocharger system that encases the turbine wheel, which is spun by exhaust gases exiting the engine. This spinning action drives the compressor wheel, which compresses incoming air before it enters the engine’s combustion chambers. The design and efficiency of the turbine housing directly influence the turbocharger’s performance, affecting engine power, fuel efficiency, and overall vehicle performance 1.

Purpose of Turbine Housing 3521838

The Turbine Housing 3521838 optimizes the flow of exhaust gases over the turbine wheel, enhancing the turbocharger’s efficiency and leading to improved engine performance. By ensuring a smooth and efficient transfer of energy from the exhaust gases to the turbine wheel, this component contributes to the engine’s efficiency and power output in commercial trucks 2.

Key Features

This Cummins part is characterized by several key features that enhance its performance and durability. Its design incorporates advanced engineering specifications to ensure optimal airflow and efficiency. The materials used in its construction are selected for their strength and resistance to high temperatures and pressures, common in turbocharger environments. These features contribute to the component’s reliability and longevity in heavy-duty applications 3.

Benefits

The benefits of the Turbine Housing 3521838 include improved engine performance, increased fuel efficiency, and enhanced durability under heavy-duty conditions. By optimizing the turbocharger’s operation, this component helps achieve higher engine power outputs and better fuel economy. Its robust construction ensures it can withstand the demanding conditions of commercial truck operations, providing long-term reliability 2.

Installation Process

Installing this part requires careful attention to detail to ensure proper fitment and function. The process involves preparing the turbocharger and engine components, aligning the housing with the turbine wheel, and securing it in place with the appropriate tools. Proper installation is crucial for the turbocharger’s efficiency and the engine’s performance 1.

Common Issues and Troubleshooting

Common issues with turbine housings include leaks, cracks, and performance decline. These issues can arise from wear and tear, improper installation, or exposure to extreme conditions. Troubleshooting these problems involves inspecting the housing for damage, ensuring proper alignment and fitment, and addressing any leaks or cracks promptly to maintain optimal turbocharger function 3.

Maintenance Tips

Regular maintenance practices can prolong the lifespan of the Turbine Housing 3521838. This includes periodic inspections for wear or damage, cleaning the housing to remove any buildup that could affect performance, and replacing worn components as necessary. Adhering to these maintenance tips helps ensure the turbocharger operates efficiently and reliably 2.

Performance Enhancements

With the Turbine Housing 3521838, potential performance enhancements include increased boost pressure, improved throttle response, and overall engine power output. These enhancements are achieved through the housing’s optimized design, which improves the efficiency of the turbocharger system. As a result, the engine can deliver more power with greater efficiency 1.

Cummins Overview

Cummins Inc. is a leader in the manufacturing of diesel engines and related technologies, with a strong presence in the commercial truck industry. The company is known for its commitment to innovation and quality, particularly in the development of turbocharger components. Cummins’ extensive product range and reputation for reliability make it a preferred choice for turbocharger components in heavy-duty applications 2.

Role of Turbine Housing 3521838 in Engine Systems

This part is an essential component in the efficient operation of various engine systems, particularly when integrated with aftermarket turbochargers and turbocharger kits. The housing encases the turbine wheel, which is driven by the exhaust gases expelled from the engine. As the turbine wheel spins, it drives the compressor wheel via a shared shaft, increasing the airflow into the engine.

When paired with a camshaft and cylinder head, the Turbine Housing enhances the engine’s overall performance by ensuring that the increased airflow is effectively utilized. The camshaft timing is optimized to take advantage of the denser air charge provided by the turbocharger, while the cylinder head facilitates better combustion by allowing for more precise control over the air-fuel mixture.

In the context of performance parts, the Turbine Housing plays a significant role in maintaining the structural integrity and efficiency of the turbocharger. It must be designed to withstand high temperatures and pressures, ensuring that the turbocharger operates within its optimal range. This is particularly important in high-performance applications where the engine is subjected to greater stress and higher RPMs 3.

Conclusion

The Turbine Housing 3521838 by Cummins is a critical component for enhancing the performance and efficiency of turbocharger systems in commercial trucks. Its advanced design, durable construction, and integration with other engine components contribute to improved engine power, fuel efficiency, and reliability. Regular maintenance and proper installation are essential for maximizing the benefits of this part in heavy-duty applications.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ ↩ ↩ -

Huzij, R., Spano, A., & Bennett, S. (2014). Modern Diesel Technology Heavy Equipment Systems. Delmar Cengage Learning.

↩ ↩ ↩ ↩ ↩ -

Hilgers, M. (2023). The Diesel Engine Second Edition. Springer Nature.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.