This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3521927 Turbine Housing is a component designed for use in heavy-duty truck engines. It is integral to the turbocharger system, contributing to the overall performance and efficiency of the engine. Understanding its purpose and significance can provide valuable insights into the operation of heavy-duty trucks.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel. This process increases the volume and pressure of air entering the engine, enhancing combustion efficiency and power output. The design and efficiency of the turbine housing play a significant role in the overall performance of the turbocharger 1.

Role of the 3521927 Turbine Housing in Truck Operation

The 3521927 Turbine Housing is specifically engineered to fit within the turbocharger system of heavy-duty trucks. It affects air intake by optimizing the flow of exhaust gases, which spins the turbine wheel more efficiently. This increased efficiency leads to better air compression, resulting in improved engine performance and fuel efficiency. The housing’s design ensures that the turbine wheel operates within its optimal range, contributing to the engine’s overall efficiency 2.

Key Features of the 3521927 Turbine Housing

The 3521927 Turbine Housing boasts several key features that enhance its performance. It is constructed from durable materials that can withstand high temperatures and pressures. The design includes precise engineering to ensure optimal exhaust gas flow and minimal turbulence. Additionally, it may feature unique characteristics such as advanced coatings or specific geometric shapes that further improve efficiency and durability.

Benefits of Using the 3521927 Turbine Housing

Utilizing the 3521927 Turbine Housing offers several benefits. It contributes to improved engine performance by ensuring efficient turbocharger operation. The durable construction enhances the longevity of the component, reducing the need for frequent replacements. Furthermore, the optimized design leads to better fuel efficiency, making it a valuable addition to any heavy-duty truck’s engine system 3.

Installation Considerations

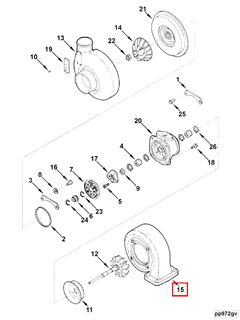

When installing the 3521927 Turbine Housing, it is important to ensure compatibility with other turbocharger components. Proper installation involves following manufacturer guidelines to avoid issues such as leaks or inefficient operation. Precautions should be taken to ensure that all connections are secure and that the housing is properly aligned within the turbocharger system.

Troubleshooting Common Issues

Common issues with the 3521927 Turbine Housing may include leaks, inefficient turbocharger operation, or damage due to high temperatures. Troubleshooting steps may involve inspecting the housing for cracks or damage, ensuring all connections are secure, and checking for proper alignment within the turbocharger system. Solutions may range from re-sealing connections to replacing damaged components.

Maintenance Tips

Regular maintenance of the 3521927 Turbine Housing is crucial for ensuring optimal performance and longevity. This includes routine cleaning to remove any buildup that may affect airflow, periodic inspection for signs of wear or damage, and following manufacturer guidelines for replacement intervals. Proper maintenance can prevent issues and ensure the turbocharger system operates efficiently.

Cummins Overview

Cummins Inc. is a well-established manufacturer with a strong reputation in the automotive industry, particularly for heavy-duty truck components. The company has a history of innovation and quality, providing reliable and high-performance parts that meet the demanding requirements of heavy-duty applications. Cummins’ commitment to excellence is evident in their range of products, including the 3521927 Turbine Housing.

Turbine Housing (Part Number 3521927) Compatibility with Cummins Engines

The Turbine Housing, identified by part number 3521927, is a critical component in the operation of certain Cummins engines. This part is integral to the engine’s turbocharger system, ensuring efficient airflow and optimal performance.

Cummins 4B3.9 Engine

The Turbine Housing for the Cummins 4B3.9 engine is designed to fit seamlessly within the turbocharger assembly. This part plays a pivotal role in directing the exhaust gases to the turbine wheel, which in turn drives the compressor to supply the engine with pressurized air. The precision engineering of the 3521927 part ensures that the turbine operates at peak efficiency, contributing to the engine’s overall power output and fuel economy.

Cummins 6B5.9 Engine

Similarly, in the Cummins 6B5.9 engine, the Turbine Housing part number 3521927 is engineered to integrate perfectly with the turbocharger system. This component is essential for managing the high-speed exhaust gases, ensuring they are channeled effectively to the turbine wheel. The design of the 3521927 part is tailored to withstand the demanding conditions within the engine, providing durability and reliability over time.

Grouping of Engines

Both the Cummins 4B3.9 and 6B5.9 engines benefit from the use of the 3521927 Turbine Housing due to its universal design features that cater to the specific needs of these engines. The part’s compatibility with these engines highlights its versatility and the importance of selecting the correct components for maintaining engine performance and longevity.

Role of Part 3521927 Turbine Housing in Engine Systems

The part 3521927 Turbine Housing is an integral component in the operation of aftermarket turbochargers and turbocharger kits. When integrated into these systems, the turbine housing works in concert with the turbocharger to enhance engine performance.

In an aftermarket turbocharger setup, the turbine housing is responsible for directing the flow of exhaust gases. These gases spin the turbine wheel, which is connected to the compressor wheel via a shaft. The compressor wheel then compresses the intake air, increasing its density and allowing more air to enter the engine’s combustion chambers. This results in improved engine efficiency and power output.

For turbocharger systems, the turbine housing plays a similar role. It ensures that the exhaust gases are efficiently channeled to spin the turbine, which in turn drives the compressor. The design of the turbine housing can affect the turbocharger’s response time and overall efficiency. A well-designed turbine housing can lead to better throttle response and increased boost pressure.

In turbocharger kits, the turbine housing is often a key component that determines the kit’s performance characteristics. These kits may include various turbine housing options to cater to different performance needs, whether for increased boost levels or improved spool-up times. The turbine housing’s design impacts how the turbocharger performs across the engine’s RPM range, making it a significant consideration in tuning and modification projects.

Overall, the part 3521927 Turbine Housing is essential for the effective operation of turbochargers, influencing both the efficiency and performance of the engine system it is a part of.

Conclusion

The 3521927 Turbine Housing is a critical component in the turbocharger systems of heavy-duty trucks, particularly those equipped with Cummins engines. Its role in directing exhaust gases to spin the turbine wheel and drive the compressor wheel is fundamental to enhancing engine performance and fuel efficiency. The durable construction and precise engineering of this Cummins part ensure its longevity and reliability, making it a valuable asset in maintaining the optimal operation of heavy-duty truck engines. Proper installation, regular maintenance, and understanding its compatibility with specific engine models are key to maximizing the benefits of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.