This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

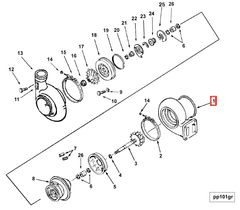

The Cummins 3521999 Turbine Housing is a component designed for use in heavy-duty truck turbocharger systems. Its purpose is to enhance the efficiency and performance of the turbocharger by managing the flow of exhaust gases. This part is significant in the operation of heavy-duty trucks as it contributes to the overall engine performance and fuel efficiency 1.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases onto the turbine wheel, which spins and drives the compressor wheel to increase air intake into the engine. This process contributes to engine performance by allowing more air to enter the combustion chamber, which can lead to more efficient burning of fuel and increased power output 2.

Role of the 3521999 Turbine Housing in Truck Operation

The 3521999 Turbine Housing plays a specific role in the turbocharger system of a truck by optimizing the flow of exhaust gases. This optimization affects the air intake and exhaust flow, leading to improved turbocharger efficiency. By ensuring that exhaust gases are directed effectively onto the turbine wheel, the housing helps maintain the balance between air intake and exhaust flow, which is vital for the engine’s performance 3.

Key Features of the 3521999 Turbine Housing

The design and construction of the 3521999 Turbine Housing include several features that enhance its functionality. It is made from durable materials that can withstand high temperatures and pressures. The structural integrity of the housing is ensured through precise manufacturing processes. Unique design elements may include specific shapes and sizes that are tailored to fit particular engine models, ensuring optimal performance.

Benefits of Using the 3521999 Turbine Housing

The advantages provided by the 3521999 Turbine Housing include improved engine efficiency, enhanced durability, and potential increases in power output. By optimizing the flow of exhaust gases, the housing contributes to more efficient turbocharger operation, which can lead to better fuel economy and increased engine power. Its durable construction ensures longevity, reducing the need for frequent replacements.

Installation Considerations

When installing the 3521999 Turbine Housing, it is important to follow guidelines and best practices to ensure proper fit and function. Compatibility with various engine models should be verified before installation. Preparatory steps may include inspecting the turbocharger system for any damage or wear that could affect the housing’s performance. Proper alignment and secure fastening are crucial for optimal operation.

Troubleshooting Common Issues

Common problems associated with turbine housings can include leaks or performance issues. Troubleshooting steps may involve inspecting the housing for cracks or damage, checking the seals for proper fit, and ensuring that the turbine wheel spins freely without obstruction. Addressing these issues promptly can help maintain the efficiency and performance of the turbocharger system.

Maintenance Tips

Regular maintenance practices can help ensure the longevity and optimal performance of the 3521999 Turbine Housing. These may include periodic inspections for signs of wear or damage, cleaning the housing to remove any buildup that could affect performance, and ensuring that all connections are secure. Following the manufacturer’s recommendations for maintenance can help prevent issues and extend the life of the component.

Cummins Corporation Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins serves customers in approximately 190 countries and territories through a network of company-owned and independent distributor facilities. The company is known for its wide range of products and its reputation for reliability and performance in the automotive industry.

Cummins Turbine Housing (Part 3521999) Compatibility

The Cummins Turbine Housing, identified by part number 3521999, is designed to fit seamlessly with specific engine models. This part is integral to the operation of the engines, ensuring efficient airflow and optimal performance.

N14 MECHANICAL Engines

The N14 MECHANICAL engines are robust and reliable, often used in heavy-duty applications. The Turbine Housing (3521999) is engineered to fit these engines, providing a secure and efficient connection that enhances the overall performance of the engine. Its design ensures that it can withstand the rigors of continuous operation, contributing to the longevity and reliability of the N14 MECHANICAL engines.

NH/NT 855 Engines

Similarly, the NH/NT 855 engines benefit from the precise fit and high-quality construction of the Turbine Housing (3521999). This part is specifically tailored to integrate with the NH/NT 855 engines, ensuring that they operate at peak efficiency. The compatibility of this Turbine Housing with these engines underscores its importance in maintaining the performance and durability of the NH/NT 855 series.

By ensuring a precise fit and reliable performance, the Cummins Turbine Housing (3521999) plays a crucial role in the functionality of both the N14 MECHANICAL and NH/NT 855 engines. Its design and engineering reflect Cummins’ commitment to providing high-quality components that enhance engine performance and reliability.

Role of Part 3521999 Turbine Housing in Engine Systems

The 3521999 Turbine Housing is an integral component in the operation of turbocharger systems, significantly influencing the performance of the engine. When integrated into a turbocharger kit, this housing directs the flow of exhaust gases, which spin the turbine wheel. The efficiency of this process is paramount for the turbocharger’s ability to compress intake air, thereby enhancing engine performance.

In the context of performance parts, the 3521999 Turbine Housing is designed to optimize the exhaust gas velocity and pressure. This optimization is essential for maximizing the turbocharger’s efficiency, which in turn boosts the engine’s power output and responsiveness. The housing’s design allows for precise control over the exhaust flow, ensuring that the turbine wheel operates at optimal speeds across a range of engine RPMs.

Furthermore, the integration of this turbine housing with other components such as the compressor housing and the turbocharger itself creates a cohesive system that significantly elevates the engine’s overall performance. The housing’s role in maintaining the correct pressure ratios and flow dynamics is vital for the turbocharger to function effectively, thereby contributing to the engine’s enhanced power delivery and efficiency.

Conclusion

The Cummins 3521999 Turbine Housing is a critical component in the turbocharger systems of heavy-duty trucks. Its role in optimizing the flow of exhaust gases directly impacts the efficiency and performance of the engine. By ensuring a precise fit and reliable operation, this part contributes to the overall durability and power output of the engine. Regular maintenance and proper installation are essential to maximize the benefits of this component.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.