This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbine Housing 3522065 by Cummins is a specialized component within the turbocharger system, designed specifically for use in heavy-duty trucks. This part is integral to the turbocharger’s operation, enhancing engine performance by optimizing the flow of exhaust gases. Its application in heavy-duty trucks underscores the importance of efficient turbocharger systems in achieving higher power outputs and improved fuel economy 1.

Basic Concepts of Turbine Housing

Turbine housings are fundamental components in turbocharger systems. They house the turbine wheel, which is spun by the flow of exhaust gases from the engine. This spinning action drives the compressor wheel, which compresses incoming air before it enters the engine’s combustion chambers. The design and efficiency of the turbine housing play a significant role in the overall performance of the turbocharger, directly influencing engine power and efficiency 2.

Purpose of Turbine Housing 3522065

The Turbine Housing 3522065 is designed to enhance the operation of a truck’s turbocharger system. It aids in improving engine efficiency and power output by optimizing the flow of exhaust gases over the turbine wheel. This optimization leads to more effective spinning of the turbine, which in turn drives the compressor wheel more efficiently, resulting in better air compression and ultimately, improved engine performance 3.

Key Features

The Turbine Housing 3522065 boasts several key features that contribute to its performance and durability. It is constructed from high-quality materials that can withstand the high temperatures and pressures of exhaust gases. Its design characteristics include precise engineering to ensure optimal airflow and efficiency. Additionally, it may feature unique attributes such as advanced coatings or specific geometric designs that further enhance its performance and longevity 4.

Benefits

Utilizing the Turbine Housing 3522065 offers several benefits. It contributes to improved turbocharger efficiency, leading to enhanced engine performance. Users may experience increases in power output and potentially better fuel economy. The housing’s durable construction and efficient design also contribute to the overall reliability and longevity of the turbocharger system.

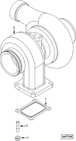

Installation Considerations

Proper installation of the Turbine Housing 3522065 is crucial for ensuring compatibility with other turbocharger components and achieving optimal performance. It is important to follow manufacturer guidelines closely, paying attention to alignment, sealing, and any specific precautions related to the housing’s unique features. Ensuring a proper fit and seal will help prevent leaks and ensure efficient operation.

Troubleshooting and Maintenance

Common issues with the Turbine Housing 3522065 may include leaks, reduced efficiency, or physical damage. Diagnostic tips include checking for proper installation, inspecting for signs of wear or damage, and ensuring all connections are secure. Regular maintenance practices, such as cleaning and inspecting for damage, can help ensure the longevity and optimal performance of the turbine housing.

Performance Impact

The Turbine Housing 3522065 affects the overall performance of the turbocharger and engine by optimizing the flow of exhaust gases. This optimization leads to more efficient spinning of the turbine wheel, which drives the compressor wheel more effectively. As a result, there may be measurable improvements in engine power, efficiency, and reliability, contributing to the overall performance of the vehicle.

Compatibility and Applications

The Turbine Housing 3522065 is designed for specific types of engines and vehicles, particularly heavy-duty trucks. Its application is tailored to meet the demands of these powerful engines, ensuring compatibility and optimal performance. Specific models or series of heavy-duty trucks may be identified for this housing, ensuring it meets the rigorous requirements of its intended use.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history in the automotive and heavy-duty truck industry, Cummins is renowned for its innovative products, quality, and reliability. The company’s extensive product range and commitment to excellence have established it as a trusted name in the industry.

L10 MECHANICAL

In the L10 MECHANICAL engine, the Turbine Housing part 3522065 plays a role in directing the flow of exhaust gases. It is designed to withstand high temperatures and pressures, ensuring the engine operates efficiently and reliably.

M11 CELECT PLUS and M11 MECHANICAL

For both the M11 CELECT PLUS and M11 MECHANICAL engines, the Turbine Housing part 3522065 is engineered to provide a robust and durable housing for the turbine. This part helps in the effective management of exhaust gases, contributing to optimal performance and longevity of the engine.

QSM11 CM570

The QSM11 CM570 engine also utilizes the Turbine Housing part 3522065. This part is designed to fit precisely within the engine’s architecture, ensuring that the turbine operates smoothly and efficiently. The housing is crafted to handle the specific demands of this engine model, contributing to its overall performance and reliability.

Role of Part 3522065 Turbine Housing in Engine Systems

The part 3522065 Turbine Housing is a component in the operation of various engine systems, particularly when integrated with aftermarket turbochargers, standard turbochargers, and turbocharger kits.

In an aftermarket turbocharger setup, the Turbine Housing provides a robust and efficient pathway for exhaust gases. These gases spin the turbine wheel, which in turn drives the compressor wheel. The efficiency of this process influences the performance and power output of the engine. The design of the Turbine Housing in aftermarket applications is often optimized for specific engine characteristics, ensuring that the turbocharger operates within its designed parameters for maximum efficiency and durability.

When considering a standard turbocharger, the Turbine Housing is integral to maintaining the balance between exhaust flow and turbine speed. It is engineered to handle the specific flow characteristics of the engine it is designed for, ensuring that the turbocharger operates efficiently across the engine’s RPM range. This balance is vital for consistent power delivery and engine responsiveness.

In a turbocharger kit, the Turbine Housing is a key component that ensures the turbocharger system functions as intended. Turbocharger kits often include various components designed to work in harmony, and the Turbine Housing is no exception. It must be compatible with the other elements of the kit, such as the compressor housing, turbine wheel, and wastegate, to ensure optimal performance and reliability. The Turbine Housing in these kits is typically designed to enhance the overall efficiency of the turbocharger system, providing improved airflow and better exhaust scavenging.

Overall, the part 3522065 Turbine Housing is a fundamental component in the efficient operation of turbocharger systems, playing a role in enhancing engine performance and reliability.

Conclusion

The Turbine Housing 3522065 by Cummins is a critical component in the turbocharger system of heavy-duty trucks, designed to optimize engine performance and efficiency. Its key features, benefits, and compatibility with various engine models highlight its importance in the automotive industry. Proper installation, maintenance, and understanding of its role in engine systems are essential for maximizing its performance and longevity.

-

Fehan, Douglas R. Design of Racing and High-Performance Engines 2004-2013. SAE International, 2013.

↩ -

Boyce, Meherwan P. Gas Turbine Engineering Handbook 4th Edition. Butterworth-Heinemann, 2011.

↩ -

Huang, Matthew. Vehicle Crash Dynamics. CRC Press, 2002.

↩ -

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.