This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

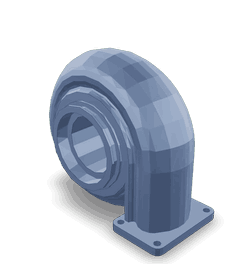

The 3522913 Turbine Housing, manufactured by Cummins, is a component designed for use in heavy-duty truck engines. Cummins, a well-established name in the automotive and heavy-duty truck industry, produces a range of parts and systems that contribute to the efficiency and performance of engines. This part is significant within this context as it plays a role in the turbocharger system, enhancing engine performance and efficiency.

Basic Concepts of Turbine Housing

A turbine housing is a component of the turbocharger system. Its function is to house the turbine wheel, which is spun by the engine’s exhaust gases. This spinning action drives the compressor wheel on the other side of the turbocharger, which compresses the intake air before it enters the engine. The efficiency of this process contributes to the overall performance of the engine by allowing it to burn fuel more effectively and produce more power 1.

Purpose of the 3522913 Turbine Housing

The 3522913 Turbine Housing is integral to the operation of a truck’s turbocharger. It facilitates the turbocharger’s function by providing a secure and efficient environment for the turbine wheel. This housing aids in increasing engine efficiency and power output by optimizing the flow of exhaust gases and ensuring that the turbine wheel operates within the designed parameters for maximum performance.

Key Features

The 3522913 Turbine Housing is characterized by its robust design and construction. It is made from materials that offer high resistance to heat and corrosion, ensuring structural integrity under the demanding conditions within a heavy-duty truck engine. Unique design elements, such as precise engineering for optimal gas flow and durable construction, enhance its performance and longevity.

Benefits

The advantages of the 3522913 Turbine Housing include improved engine performance through more efficient turbocharging, increased fuel efficiency as a result of better air-fuel mixture, and durability under high-stress conditions. These benefits contribute to the overall effectiveness and reliability of the engine.

Installation Considerations

When installing the 3522913 Turbine Housing, it is important to follow guidelines and best practices to ensure compatibility with the engine model and proper fitting and sealing. This includes checking for any manufacturer-specific instructions and ensuring that all connections are secure to prevent leaks and ensure optimal performance.

Troubleshooting and Maintenance

Common issues with turbine housings can include leaks, cracks, or damage from heat and corrosion. Diagnostic tips for identifying problems include checking for unusual noises, performance drops, or visible damage. Maintenance practices to ensure the longevity and optimal performance of the 3522913 Turbine Housing involve regular inspections, cleaning, and addressing any issues promptly to prevent further damage.

Performance Enhancements

Upgrades or modifications to the turbine housing can affect engine performance. Aftermarket options may offer improvements in material, design, or efficiency. These modifications can potentially lead to increased power output, better fuel efficiency, or enhanced durability, depending on the specific changes made.

Thermal Management

The turbine housing plays a role in managing exhaust gas temperatures. Effective thermal management is vital for the efficiency and reliability of the turbocharger system. By controlling the temperature of the exhaust gases, the turbine housing helps maintain the optimal operating conditions for the turbocharger, contributing to the engine’s overall performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive and heavy-duty truck industry. Its product range includes engines, filtration systems, and related components, all designed to meet the demanding requirements of modern transportation and power generation applications.

Role of 3522913 Turbine Housing in Engine Systems

When integrating the 3522913 Turbine Housing into various engine systems, its function becomes apparent in enhancing the performance and efficiency of the turbocharger. This component is designed to work seamlessly with both aftermarket turbochargers and performance parts, ensuring optimal airflow management and thermal efficiency.

In the context of an aftermarket turbocharger, the Turbine Housing plays a significant role in directing the exhaust gases to spin the turbine wheel. This action is essential for compressing the intake air, which subsequently increases the engine’s power output. The design of the Turbine Housing affects the turbocharger’s response time and overall efficiency, making it a key factor in the performance tuning of aftermarket systems.

For performance parts, particularly within a turbocharger kit, the Turbine Housing is integral to maintaining the balance between air intake and exhaust flow. Its precise engineering ensures that the turbocharger operates within its optimal range, preventing issues such as lag or excessive heat buildup. The housing’s design can influence the turbocharger’s spool-up time and the peak boost pressure, directly impacting the engine’s drivability and power delivery.

Conclusion

The 3522913 Turbine Housing is a fundamental component in the effective operation of turbochargers. Its role in managing exhaust gas flow and turbine speed is essential for achieving the desired performance enhancements in both aftermarket and performance-oriented engine systems. Proper installation, maintenance, and understanding of its function are crucial for maximizing the benefits of this Cummins part in heavy-duty truck engines.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.