This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

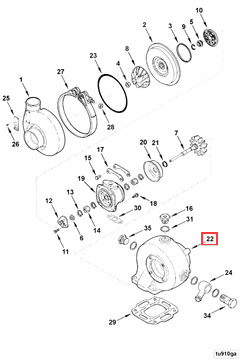

The Turbine Housing 3524425 by Cummins is a specialized component designed for use in turbocharger systems, particularly in heavy-duty trucks. This part is integral to the turbocharger’s operation, enhancing engine efficiency and performance. Its application in heavy-duty trucks underscores the importance of robust and reliable components in demanding environments.

Basic Concepts of Turbine Housing

Turbine housings are fundamental to the operation of turbocharger systems. They house the turbine wheel, which is driven by exhaust gases exiting the engine. The relationship between the turbine housing and the compressor housing is symbiotic; as the turbine wheel spins, it drives the compressor wheel, which compresses incoming air before it enters the engine. This process increases the engine’s air intake, leading to more efficient combustion and enhanced performance. The design and efficiency of the turbine housing play a significant role in the overall performance of the turbocharger system 1.

Purpose of Turbine Housing 3524425

The Turbine Housing 3524425 is designed to optimize the flow of exhaust gases over the turbine wheel. By efficiently channeling exhaust gases, it ensures that the turbine wheel spins at optimal speeds, which in turn drives the compressor wheel more effectively. This contributes to increased engine efficiency and performance, allowing the engine to operate more effectively under a variety of conditions 2.

Key Features

The Turbine Housing 3524425 features a design that maximizes the efficiency of exhaust gas flow. It is constructed from high-quality materials that offer durability and resistance to the high temperatures and pressures present in turbocharger systems. Unique characteristics of this turbine housing include precision engineering for optimal performance and durability under demanding conditions 3.

Benefits

Using the Turbine Housing 3524425 offers several benefits. It contributes to improved engine performance by ensuring efficient turbocharger operation. Additionally, it enhances fuel efficiency by allowing the engine to operate more effectively. The durable construction of this turbine housing ensures longevity and reliability, even in the challenging environments typical of heavy-duty truck applications 4.

Installation Considerations

Proper installation of the Turbine Housing 3524425 is crucial for ensuring optimal performance and durability. It is important to verify compatibility with the specific engine model to ensure proper fit and function. Following manufacturer recommendations during installation helps to avoid common issues and ensures the turbocharger system operates as designed.

Troubleshooting and Maintenance

Common issues with turbine housings can include leaks, cracks, or a decline in performance. Regular inspection and maintenance can help identify and address these issues before they lead to more significant problems. Maintenance tips include checking for signs of wear or damage, ensuring proper installation, and following recommended service intervals to maintain optimal performance and longevity.

Performance Optimization

To optimize the performance of the Turbine Housing 3524425, consider tuning adjustments that can fine-tune the turbocharger system for specific applications. Upgrades to other components within the turbocharger system can also enhance overall performance. Best practices for maximizing efficiency and power output include regular maintenance, proper installation, and monitoring the system for signs of wear or inefficiency.

Cummins Overview

Cummins Inc. is a leader in the design and manufacturing of diesel engines, including turbocharger components. With a history of innovation and a commitment to quality, Cummins has established a reputation for producing reliable and high-performance components. Their turbocharger components, including the Turbine Housing 3524425, are designed with precision engineering and high-quality materials to ensure durability and efficiency in demanding applications.

Role of Part 3524425 Turbine Housing in Engine Systems

The Turbine Housing 3524425 is an integral component in the efficient operation of aftermarket turbochargers, turbochargers, and turbocharger kits. Its primary function is to house the turbine wheel, which is driven by the exhaust gases expelled from the engine.

In an aftermarket turbocharger setup, the Turbine Housing works in conjunction with the compressor housing to enhance the overall performance of the engine. The turbine housing directs the flow of exhaust gases onto the turbine wheel, which spins at high speeds. This rotational energy is then transferred via a shaft to the compressor wheel, increasing the pressure of the air entering the engine.

When integrated into a standard turbocharger, the Turbine Housing ensures optimal airflow and pressure ratios. The design of the housing affects the turbocharger’s efficiency and response time, directly influencing the engine’s power output and fuel efficiency.

In a turbocharger kit, which often includes various components aimed at upgrading or replacing existing turbocharger systems, the Turbine Housing plays a significant role. It must be precisely matched with other components such as the turbine wheel, shaft, and bearing system to ensure seamless integration and performance. The housing’s design can also impact the turbocharger’s ability to handle higher boost levels, making it a key consideration in performance tuning.

Conclusion

The Turbine Housing 3524425 by Cummins is a critical component in enhancing the performance and efficiency of turbocharger systems in heavy-duty engines. Its design, durability, and integration with other turbocharger components are essential for maintaining optimal engine performance and reliability. Proper installation, regular maintenance, and performance tuning are key to maximizing the benefits of this part in demanding applications.

-

Automotive Braking Systems CDX Master Automotive Technician Series, Nicholas Goodnight and Kirk VanGelder, Jones Bartlett Learning, 2019.

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing, 2011.

↩ -

Engine Oils and Automotive Lubrication Mechanical Engineering Book 80, Wilfried J Bartz, CRC Press, 2019.

↩ -

Diesel Engine System Design, Qianfan Xin, Woodhead Publishing Limited, 2011.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.