This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

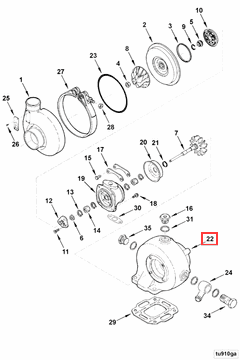

The Cummins 3525691 Turbine Housing is a component designed for use in heavy-duty truck engines. Its purpose is to house the turbine wheel within the turbocharger system, playing a significant role in enhancing engine performance and efficiency. Understanding its function and significance is key to maintaining and optimizing the performance of heavy-duty trucks.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel. This process increases the amount of air entering the engine, thereby boosting power output and efficiency. The design and efficiency of the turbine housing directly influence the performance of the turbocharger and, by extension, the engine 1.

Role of the 3525691 Turbine Housing in Truck Operation

This part is specifically engineered to fit within the turbocharger system of heavy-duty trucks. It plays a role in optimizing the flow of exhaust gases to the turbine wheel, which affects the air intake and overall engine efficiency. By efficiently directing exhaust gases, it helps in achieving a balanced turbocharger operation, contributing to the truck’s power output and fuel efficiency 2.

Key Features of the 3525691 Turbine Housing

The design and construction of this Cummins part incorporate several features that enhance its performance and durability. It is made from high-quality materials that offer resistance to heat and corrosion, ensuring longevity and reliable operation. The housing’s design also focuses on maximizing the efficiency of exhaust gas flow to the turbine wheel, which is crucial for optimal turbocharger performance 3.

Benefits of Using the 3525691 Turbine Housing

Utilizing this part in a truck’s turbocharger system offers several advantages. These include improved engine performance due to more efficient turbocharger operation, increased durability thanks to its robust construction, and enhanced efficiency in fuel consumption. These benefits contribute to the overall effectiveness and reliability of the truck.

Installation Considerations

When installing the 3525691 Turbine Housing, it is important to ensure compatibility with other turbocharger components. Proper installation requires the use of appropriate tools and adherence to manufacturer guidelines to ensure a secure and efficient fit. Attention to detail during installation helps in achieving optimal performance and longevity of the turbocharger system.

Maintenance and Troubleshooting

Regular maintenance of this part is vital for ensuring its longevity and optimal performance. This includes inspecting for signs of wear or damage, cleaning to remove any buildup that could affect performance, and ensuring all connections are secure. Common issues may include leaks or reduced efficiency, which can often be addressed through proper maintenance practices.

Performance Impact

The 3525691 Turbine Housing influences the overall performance of the truck by contributing to more efficient turbocharger operation. This results in improvements in fuel efficiency, increased power output, and enhanced reliability of the engine. Its role in the turbocharger system is fundamental to achieving these performance benefits.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engine components, Cummins has established a reputation for excellence. The company’s dedication to advancing technology and meeting the needs of its customers underscores its position as a trusted provider in the industry.

Cummins Turbine Housing Part 3525691 Compatibility

This part, identified as a Turbine Housing, is a critical component in the engine’s turbocharger system. It is designed to fit seamlessly within the architecture of several Cummins engines, ensuring optimal performance and durability.

4B3.9 Engine

The Turbine Housing part 3525691 is specifically engineered to integrate with the 4B3.9 engine. This engine is known for its robust design and reliability, often utilized in heavy-duty applications. The turbine housing plays a vital role in directing the exhaust gases to the turbine wheel, facilitating efficient turbocharging and enhancing the engine’s power output.

6B5.9 Engine

Similarly, the 6B5.9 engine benefits from the precise fit of the Cummins part 3525691. This engine, recognized for its superior performance and efficiency, relies on the turbine housing to maintain the structural integrity of the turbocharger system. The part ensures that the exhaust gases are channeled effectively, contributing to the engine’s overall performance and longevity.

Grouping of Engines

Both the 4B3.9 and 6B5.9 engines are part of Cummins’ lineup of high-performance engines, often used in demanding industrial and commercial applications. The Turbine Housing part 3525691 is integral to these engines, providing a reliable connection point for the turbocharger system. Its design ensures that it fits perfectly within the engine’s architecture, supporting the efficient operation of the turbocharger and contributing to the engine’s overall performance.

Role of Part 3525691 Turbine Housing in Engine Systems

The turbine housing, identified by part number 3525691, is an integral component in the efficient operation of various engine systems, particularly when integrated with aftermarket turbochargers and turbocharger kits.

When paired with an aftermarket turbocharger, the turbine housing facilitates the conversion of exhaust gases into mechanical energy. This energy is then used to spin the turbine wheel, which in turn drives the compressor wheel. The compressor wheel compresses the intake air, enhancing engine performance by allowing more air into the combustion chamber. The design and material of the turbine housing are optimized to withstand high temperatures and pressures, ensuring reliable performance under demanding conditions.

In conjunction with a turbocharger kit, the turbine housing plays a pivotal role in the overall efficiency of the turbocharging system. The housing is engineered to match the specific flow characteristics of the turbocharger, ensuring that exhaust gases are directed efficiently to the turbine wheel. This efficient flow management is essential for maximizing the turbocharger’s potential, leading to improved engine response and power output.

The integration of a cooler, typically an intercooler, with the turbine housing and turbocharger system further enhances engine performance. The cooler reduces the temperature of the compressed air from the turbocharger before it enters the engine. This reduction in temperature increases the air density, allowing for more efficient combustion and higher power output. The turbine housing must be designed to accommodate the increased airflow and pressure changes resulting from the cooler’s operation.

Engine oil also interacts with the turbine housing indirectly through the lubrication of the turbocharger’s rotating components. Proper lubrication is essential to reduce friction and wear on the turbine and compressor wheels. The turbine housing must be designed to ensure that oil seals and passages are effectively managed, preventing oil leaks and maintaining the integrity of the turbocharging system.

Conclusion

In summary, the turbine housing (part 3525691) is a key component that ensures the efficient operation of aftermarket turbochargers, turbocharger kits, coolers, and engine oil systems. Its design and integration with these components are essential for achieving optimal engine performance and reliability.

-

Design of Racing and High-Performance Engines 2004-2013, Douglas R. Fehan, SAE International, 2013

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.