This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

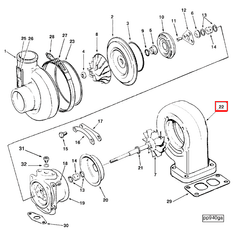

The Turbine Housing 3527122 by Cummins is a component designed to enhance the performance of heavy-duty trucks. It is integral to the turbocharger system, contributing to the efficient operation of the engine. This housing is engineered to withstand the demanding conditions of heavy-duty applications, ensuring reliable performance and durability.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases onto the turbine wheel, which spins and drives the compressor wheel. This process increases the airflow into the engine, thereby enhancing its performance. The design and efficiency of the turbine housing play a significant role in the overall performance of the turbocharger and, by extension, the engine 1.

Purpose of Turbine Housing 3527122

The Turbine Housing 3527122 is designed to optimize the flow of exhaust gases, which in turn improves the efficiency of the turbocharger. By enhancing the turbocharger’s performance, this housing contributes to increased engine efficiency and power output. It is tailored to meet the specific requirements of heavy-duty truck engines, ensuring that they operate at peak performance under various conditions.

Key Features

The Turbine Housing 3527122 is constructed using high-quality materials that offer excellent resistance to heat and corrosion. Its design ensures structural integrity, allowing it to withstand the high pressures and temperatures associated with heavy-duty truck engines. Unique design elements, such as precise turbine geometry, contribute to its efficient operation and durability 2.

Benefits

The advantages of the Turbine Housing 3527122 include improved engine performance, enhanced durability, and increased reliability. Its efficient design allows for better airflow and increased power output, while its robust construction ensures long-term operation under demanding conditions. These benefits make it a valuable component for heavy-duty truck engines.

Installation Process

Proper installation of the Turbine Housing 3527122 involves several steps. It is important to ensure that the engine is cool before beginning the installation process. The necessary tools and any prerequisites, such as gaskets or seals, should be prepared beforehand. Following the manufacturer’s instructions for torque specifications and alignment is crucial to ensure a secure and efficient installation.

Common Issues and Troubleshooting

Common problems associated with turbine housings can include leaks, cracks, or reduced efficiency. These issues may arise from improper installation, material fatigue, or exposure to extreme conditions. Troubleshooting steps may involve inspecting the housing for visible damage, checking for proper alignment and sealing, and ensuring that all connections are secure 3.

Maintenance Tips

To ensure the longevity and optimal performance of the Turbine Housing 3527122, regular maintenance is recommended. This includes periodic inspections for signs of wear or damage, cleaning to remove any buildup of soot or debris, and ensuring that all connections are tight and secure. Adhering to these maintenance practices can help prevent issues and extend the component’s lifespan.

Compatibility and Applications

The Turbine Housing 3527122 is designed for specific types of engines and truck models. It is important to consult the manufacturer’s guidelines for compatibility information to ensure that it is suitable for the intended application. Specific application notes may provide additional insights into its use and integration within the engine system.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history of innovation and quality, Cummins has established a strong reputation in the heavy-duty truck industry. Their product range includes a variety of components and systems designed to enhance the performance and reliability of heavy-duty engines.

Application in Engine Models

- 6C8.3: The Turbine Housing part 3527122 is specifically designed for the 6C8.3 engine, where it plays a pivotal role in the turbocharger’s functionality. This part ensures that the exhaust gases are directed efficiently, which is crucial for maintaining optimal engine performance and longevity.

- Other Cummins Engines: While the 6C8.3 is a notable application, the Turbine Housing part 3527122 is also compatible with other Cummins engine models. This versatility underscores its importance across various engine configurations, providing a consistent and reliable performance across different applications.

Importance of the Turbine Housing

The Turbine Housing part 3527122 is essential for several reasons:

- Efficiency: It ensures that the turbocharger operates at peak efficiency, which directly impacts the engine’s power output and fuel economy.

- Durability: Made from high-quality materials, this part is designed to withstand the harsh conditions within the engine, ensuring a long service life.

- Compatibility: Its design allows it to fit seamlessly with various engine models, making it a versatile component in the Cummins engine lineup.

Integration with Turbocharger

When integrated with a turbocharger, the turbine housing plays a significant role in converting the energy from the engine’s exhaust into rotational energy. This energy is then transferred to the compressor wheel via a shared shaft, allowing the turbocharger to compress incoming air and improve engine efficiency and power output.

Role in Turbocharger Kit

In a turbocharger kit, the turbine housing is often one of the key components. It is designed to work in harmony with other parts of the kit, such as the compressor housing, center housing, and wastegate. The efficiency of the turbine housing directly impacts the overall performance of the turbocharger kit, influencing factors such as response time, boost pressure, and thermal efficiency.

Importance at Turbocharger Location

The location of the turbocharger in the engine system is determined by various factors, including the design of the engine and the specific requirements of the vehicle. The turbine housing must be precisely positioned to ensure optimal flow of exhaust gases. Its design and placement are critical for minimizing backpressure and maximizing the efficiency of the turbocharger.

Function in Turbocharger Systems

In turbocharger systems, the turbine housing is responsible for housing the turbine wheel and directing exhaust gases to it. The design of the housing can vary depending on the specific application, with some designs optimizing for low-end torque and others for high-end power. The efficiency of the turbine housing in directing exhaust gases can significantly influence the performance characteristics of the turbocharger system.

Conclusion

The Turbine Housing 3527122 by Cummins is a critical component in the turbocharger system of heavy-duty engines. Its design and functionality are essential for enhancing engine performance, ensuring durability, and maintaining reliability under demanding conditions. Proper installation, regular maintenance, and understanding its role within the turbocharger system are key to maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.