This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

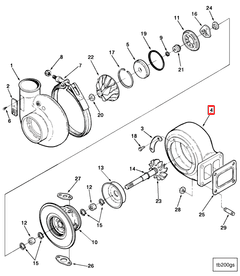

The Cummins 3528216 Turbine Housing is a component designed to enhance the performance of turbocharger systems in heavy-duty trucks. It plays a role in optimizing engine performance by efficiently managing exhaust gas flow, which is vital for the turbocharger’s operation. This housing is part of Cummins’ commitment to providing reliable and high-performing parts for the automotive and heavy-duty truck industries.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbocharger systems. They are responsible for directing exhaust gases from the engine to the turbine wheel. The design and construction of the housing impact how effectively these gases are channeled, influencing the turbocharger’s efficiency. A well-designed turbine housing can significantly enhance turbo efficiency by ensuring a smooth and consistent flow of exhaust gases, which in turn drives the turbine wheel at optimal speeds 1.

Purpose of the 3528216 Turbine Housing

The 3528216 Turbine Housing is specifically engineered to improve the operation of a truck’s engine. It contributes to the turbocharger system by facilitating improved airflow and increasing turbo speed. This results in enhanced engine performance, allowing for better power output and efficiency. The housing’s design is tailored to work in harmony with the engine’s requirements, ensuring that the turbocharger operates within its optimal range.

Key Features

The Cummins 3528216 Turbine Housing is characterized by its robust design and construction. It is made from high-quality materials that ensure structural integrity and durability. The housing features a precise design that enhances its performance, including optimized exhaust gas flow paths and a secure fit within the engine system. These features contribute to its reliability and effectiveness in demanding applications.

Benefits

The advantages of the 3528216 Turbine Housing include improved turbo response, which leads to quicker acceleration and better overall engine performance. It also contributes to increased power output, allowing the engine to operate more efficiently. Additionally, the housing helps in enhancing fuel efficiency and reducing emissions, making it a valuable component for both performance and environmental considerations.

Installation Considerations

When installing the 3528216 Turbine Housing, it is important to follow guidelines and best practices to ensure compatibility with the engine model. The installation process requires specific tools and equipment, and a step-by-step procedure should be adhered to for a successful integration. Proper installation is key to achieving the housing’s full performance benefits and ensuring the longevity of the turbocharger system.

Troubleshooting and Maintenance

Common issues with turbine housings can include leaks, cracks, or inefficient exhaust gas flow. Diagnostic procedures are available to identify these problems, allowing for timely repairs or replacements. Regular maintenance, including inspections and cleaning, is recommended to ensure the optimal performance and longevity of the 3528216 Turbine Housing. Proper care can prevent many issues and extend the component’s service life.

Performance Enhancements

The 3528216 Turbine Housing can be integrated into a broader strategy for enhancing engine performance. It is compatible with various turbocharger components and can be part of tuning options to further optimize engine output. When combined with other performance upgrades, the housing can contribute to significant improvements in engine efficiency and power.

Cummins Overview

Cummins Inc. is a renowned manufacturer with a strong presence in the automotive and heavy-duty truck industries. The company has a history of innovation and quality, offering a wide range of products designed to meet the demanding needs of these sectors. Cummins is known for its commitment to providing reliable and high-performing parts, including the 3528216 Turbine Housing, which reflects the brand’s dedication to excellence and customer satisfaction.

Understanding the Role of Turbine Housing in Engine Systems

When examining the integration of part 3528216, the Turbine Housing, within various engine systems, it’s essential to grasp its interaction with other components to optimize performance and efficiency.

Interaction with Turbocharger

The Turbine Housing is a fundamental component of the turbocharger system. It encases the turbine wheel, which is driven by the exhaust gases expelled from the engine. The design of the Turbine Housing significantly influences the velocity and direction of these gases, impacting the turbocharger’s ability to spin the turbine wheel at high speeds. This, in turn, drives the compressor wheel, enhancing air intake and boosting engine performance 2.

Contribution to Performance Parts

In the realm of performance parts, the Turbine Housing plays a pivotal role. Upgrades or modifications to the Turbine Housing can lead to substantial improvements in engine performance. For instance, a larger Turbine Housing can accommodate more exhaust flow, allowing the turbocharger to operate more efficiently at higher RPMs. Conversely, a smaller housing might provide better low-end response, making the turbocharger more responsive at lower RPMs. The choice of Turbine Housing can thus be tailored to specific performance goals, whether it’s increased power, improved throttle response, or enhanced efficiency.

Integration within Turbocharger Kits

When part of a turbocharger kit, the Turbine Housing works in concert with other components such as the compressor housing, center housing, and wastegate. The efficiency of the Turbine Housing directly affects the overall performance of the turbocharger kit. A well-designed Turbine Housing ensures that the exhaust gases are utilized effectively, minimizing energy loss and maximizing the turbocharger’s potential. This synergy between components is vital for achieving the desired performance enhancements in the engine system.

Impact on Overall Engine Performance

The Turbine Housing’s role extends beyond the turbocharger itself, influencing the engine’s overall performance. By efficiently managing exhaust gas flow, it contributes to better turbo spool-up times, reduced lag, and increased power output. Additionally, the thermal properties of the Turbine Housing material can affect heat management within the engine bay, further impacting performance and reliability.

Conclusion

The Turbine Housing part 3528216, manufactured by Cummins, is a critical component in several engine configurations. Its design and functionality are integral to the performance of turbochargers and, by extension, the engine as a whole. Proper installation, maintenance, and understanding of its role within the engine system are essential for maximizing its benefits and ensuring the longevity and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.