This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbine Housing 3531727 by Cummins is a component designed for use in turbocharger systems, specifically tailored for heavy-duty trucks. This part is integral to the turbocharger’s function, enhancing the engine’s performance by optimizing the flow of exhaust gases. Its application in heavy-duty trucks underscores the importance of robust and efficient turbocharger components in demanding environments 1.

Basic Concepts of Turbine Housing

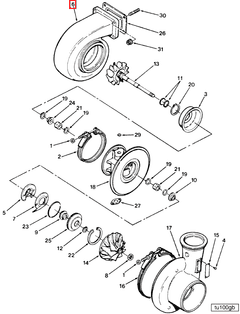

A turbine housing is a component of a turbocharger system. It encases the turbine wheel, which is spun by the flow of exhaust gases from the engine. This spinning action drives the compressor wheel, which compresses incoming air before it enters the engine’s combustion chambers. The design and efficiency of the turbine housing play a significant role in the turbocharger’s ability to enhance engine performance by improving airflow and combustion efficiency 2.

Purpose of Turbine Housing 3531727

The Turbine Housing 3531727 is designed to improve the efficiency and power output of a truck’s engine. By optimizing the path of exhaust gases, it allows the turbine wheel to spin more efficiently, which in turn drives the compressor wheel more effectively. This results in a greater volume of compressed air being delivered to the engine, enhancing combustion efficiency and power output.

Key Features

The Turbine Housing 3531727 boasts several key features that contribute to its performance and durability. Its design is engineered to maximize the efficiency of exhaust gas flow, ensuring optimal turbine wheel speed. The materials used in its construction are selected for their ability to withstand high temperatures and pressures, ensuring longevity and reliability. Additionally, any unique attributes, such as specific geometric designs or coatings, further enhance its performance and resistance to wear.

Benefits

Utilizing the Turbine Housing 3531727 offers several benefits. It contributes to improved engine performance by enhancing the efficiency of the turbocharger system. This results in increased power output and better throttle response. Furthermore, the optimized airflow can lead to increased fuel efficiency, making it a valuable component for heavy-duty truck applications. Its durable construction ensures it can withstand the rigors of heavy-duty use, providing long-term reliability.

Installation Considerations

Proper installation of the Turbine Housing 3531727 is crucial for ensuring optimal performance and compatibility with other turbocharger components. It is important to follow manufacturer guidelines to ensure a secure fit and proper alignment. Additionally, precautions should be taken to avoid damage to the housing or other components during installation. Compatibility with the specific turbocharger model and engine type should be verified before installation.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are key to ensuring the longevity and performance of the Turbine Housing 3531727. Common issues may include leaks, reduced efficiency, or physical damage. Inspections should be conducted regularly to check for signs of wear or damage, such as cracks or deformations. Maintenance tips include keeping the housing clean from debris and ensuring all connections are secure and leak-free.

Performance Impact

The incorporation of the Turbine Housing 3531727 into a turbocharger system can lead to notable improvements in engine performance. By optimizing the flow of exhaust gases and enhancing the efficiency of the turbocharger, it contributes to increased power output, improved fuel efficiency, and greater reliability. These enhancements are particularly beneficial in heavy-duty truck applications, where performance and durability are paramount.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for producing high-quality automotive components, including turbochargers and related parts. The company’s commitment to innovation, quality, and customer satisfaction has made it a trusted name in the industry, particularly in the heavy-duty truck sector.

Turbine Housing (Part 3531727) in Cummins Engines

The Turbine Housing, identified as part 3531727, is a critical component in the Cummins N14 CELECT PLUS and N14 MECHANICAL engines. This part is integral to the operation of the turbocharger system, ensuring efficient airflow and optimal engine performance.

N14 CELECT PLUS Engine

In the N14 CELECT PLUS engine, the Turbine Housing is designed to work seamlessly with the electronic control unit (ECU) to manage the turbocharger’s operation. The housing’s precision engineering ensures that it can withstand the high temperatures and pressures generated by the exhaust gases, contributing to the engine’s overall efficiency and longevity.

N14 MECHANICAL Engine

For the N14 MECHANICAL engine, the Turbine Housing plays a similar role but operates without the electronic control system. The mechanical linkage system relies on the housing’s durability and precision to maintain consistent turbocharger performance. The robust design of the Turbine Housing ensures that it can endure the demanding conditions of the engine’s operation, providing reliable power output.

Common Features

Both engines benefit from the Turbine Housing’s ability to direct exhaust gases efficiently, enhancing the turbocharger’s responsiveness and reducing lag. The housing’s design also facilitates proper heat dissipation, which is crucial for maintaining the engine’s performance under various operating conditions. The use of high-quality materials ensures that the Turbine Housing can withstand the rigors of continuous use, contributing to the engine’s overall reliability and efficiency.

Role of Part 3531727 Turbine Housing in Engine Systems

This part is an essential component in the operation of various turbocharger systems, including aftermarket turbochargers, Heat3B turbochargers, and Heat60 turbochargers. This housing encases the turbine wheel, which is driven by the exhaust gases exiting the engine.

In an aftermarket turbocharger setup, the 3531727 Turbine Housing is often utilized to enhance the performance capabilities beyond the stock specifications. It is engineered to handle increased exhaust flow, which is a direct result of modifications such as larger injectors, higher-flowing cylinder heads, or the installation of a performance ECU. The housing’s design allows for efficient energy transfer from the exhaust gases to the turbine wheel, thereby spinning it at high speeds. This increased speed leads to a corresponding increase in the compressor wheel’s speed on the other side of the turbocharger, resulting in denser air being forced into the engine’s combustion chambers.

For Heat3B turbocharger applications, the 3531727 Turbine Housing is integral to maintaining the balance between spool-up time and peak boost pressure. The housing is designed to optimize the flow characteristics specific to the Heat3B’s turbine wheel geometry. This ensures that the turbocharger can achieve a rapid response to throttle inputs while still being capable of sustaining high boost levels at elevated engine speeds.

In Heat60 turbocharger systems, the 3531727 Turbine Housing plays a similarly important role. Given the Heat60’s larger size and higher flow capacity, the housing must be precisely engineered to manage the significantly increased volume of exhaust gases. This management is vital for preventing issues such as turbine lag and ensuring that the turbocharger can deliver consistent performance across a wide range of engine operating conditions.

Overall, the 3531727 Turbine Housing is a key component in enhancing the efficiency and performance of turbocharger systems. Its proper integration and function are essential for achieving the desired power output and responsiveness in both stock and modified engine configurations.

Conclusion

The Turbine Housing 3531727 by Cummins plays a vital role in enhancing the performance and efficiency of turbocharger systems in heavy-duty trucks. Its design and construction are tailored to withstand the demanding conditions of heavy-duty use, ensuring long-term reliability and optimal engine performance. Proper installation, regular maintenance, and timely troubleshooting are essential for maximizing the benefits of this Cummins part. Its integration into various turbocharger systems, including aftermarket, Heat3B, and Heat60 turbochargers, underscores its versatility and importance in achieving desired power output and responsiveness.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.