This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbine Housing 3531731 by Cummins is a component designed for use in turbocharger systems, specifically tailored for heavy-duty trucks. This part plays a role in the turbocharger system by directing exhaust gases to spin the turbine, which in turn drives the compressor wheel to increase airflow into the engine. Its application in heavy-duty trucks is important for optimizing engine performance and efficiency.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbocharger systems. They serve to channel exhaust gases from the engine to the turbine wheel, which spins at high speeds to drive the compressor. This process increases the volume of air entering the engine, enhancing combustion efficiency and power output. The design and material of the turbine housing are important for withstanding high temperatures and pressures, ensuring reliable operation 1.

Role of the 3531731 Turbine Housing in Truck Operation

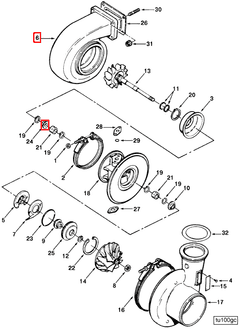

This Cummins part is specifically engineered to interact with other turbocharger components to optimize the performance of a truck’s engine. It houses the turbine wheel and directs exhaust gases efficiently to spin the turbine. This spinning action is transferred to the compressor wheel via a shaft, increasing the airflow into the engine. The precise design of the 3531731 housing ensures that it works in harmony with the compressor housing and other turbocharger elements to maintain engine efficiency and power.

Key Features of the 3531731 Turbine Housing

This part is characterized by its robust design and construction. It is made from high-quality materials that can withstand the extreme conditions within a turbocharger system. The housing’s shape is meticulously engineered to optimize the flow of exhaust gases, enhancing turbine efficiency. Additionally, it features precise machining and durable coatings that contribute to its performance and longevity.

Benefits of Using the 3531731 Turbine Housing

Utilizing this part in a turbocharger system offers several advantages. It contributes to improved engine efficiency by ensuring optimal airflow and combustion. The housing’s design allows for increased power output, making it suitable for heavy-duty applications. Furthermore, its durable construction enhances the reliability of the turbocharger system, reducing the likelihood of failures and maintenance needs.

Installation and Integration

Proper installation of the 3531731 Turbine Housing is important for ensuring its effective operation within the turbocharger system. It requires careful alignment with the turbine wheel and secure fastening to prevent leaks. Preparations may include cleaning the mating surfaces and inspecting the gaskets for any damage. Following manufacturer guidelines during installation ensures that the housing integrates seamlessly with the turbocharger and engine system.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the longevity and optimal performance of the 3531731 Turbine Housing. This includes regular inspections for signs of wear, damage, or leaks. Cleaning the housing to remove any buildup of soot or debris is also important. Troubleshooting may involve checking for proper alignment, securing all fasteners, and ensuring that gaskets are in good condition to prevent leaks.

Common Issues and Solutions

Common problems associated with turbine housings include leaks, damage from high temperatures, and efficiency losses due to wear. Solutions may involve replacing damaged gaskets, repairing or replacing the housing if it is cracked or warped, and ensuring that the turbine wheel is properly aligned and balanced. Regular maintenance can help identify and address these issues before they lead to significant problems.

Performance Enhancements

While the 3531731 Turbine Housing is designed for optimal performance, there may be opportunities for upgrades or modifications to further enhance engine performance. This could include using higher-efficiency turbine wheels, improving the housing’s thermal coatings, or modifying the housing’s shape for better gas flow. Any modifications should be done with careful consideration of the engine’s requirements and the turbocharger system’s limitations.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the automotive and heavy-duty truck industry, Cummins is known for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and technological advancements have made it a preferred choice for demanding applications.

Turbine Housing (Part 3531731) in Cummins Engines

The Turbine Housing (part 3531731) is a component in Cummins engines, including the N14 CELECT PLUS. This part is integral to the engine’s turbocharger system, ensuring efficient airflow and optimal performance.

In the N14 CELECT PLUS engine, the Turbine Housing is designed to withstand high temperatures and pressures, providing a durable and reliable housing for the turbine wheel. This component is important for the proper functioning of the turbocharger, which enhances the engine’s power output and efficiency.

The Turbine Housing is engineered to fit seamlessly within the engine’s architecture, ensuring a precise and secure fit. This precision is important for maintaining the integrity of the turbocharger system and preventing any potential leaks or performance issues.

For the N14 CELECT PLUS engine, the Turbine Housing is a key part of the engine’s overall design, contributing to its robust performance and reliability. This component is manufactured to meet Cummins’ stringent quality standards, ensuring it performs optimally under various operating conditions.

Role of Part 3531731 Turbine Housing in Engine Systems

The integration of part 3531731 Turbine Housing within engine systems, particularly those utilizing the Heat60 Turbocharger, is a fundamental aspect of enhancing performance and efficiency. This component is meticulously designed to work in harmony with various parts of the turbocharger system, ensuring optimal functionality and durability.

Interaction with the Turbocharger

The Turbine Housing is a key element in the turbocharger’s operation. It is responsible for directing the flow of exhaust gases, which spin the turbine wheel. This spinning action is transferred to the compressor wheel via a shared shaft, thereby compressing the intake air and boosting engine performance. The design of the Turbine Housing, including its shape and volume, significantly influences the turbocharger’s response and efficiency.

Contribution to the Turbocharger Kit

When part of a turbocharger kit, the Turbine Housing plays a role in the overall performance upgrade. It is engineered to complement other components within the kit, such as the compressor housing, turbine wheel, and bearing system. The synergy between these parts ensures that the turbocharger operates within its designed parameters, providing the desired increase in power and efficiency.

Enhancing Engine Performance

The effectiveness of the Turbine Housing in channeling exhaust gases directly impacts the engine’s performance. By optimizing the flow and pressure of these gases, it contributes to a more efficient combustion process. This, in turn, leads to improved throttle response, increased power output, and better fuel efficiency.

Durability and Reliability

In addition to performance enhancement, the Turbine Housing is also pivotal in ensuring the durability and reliability of the turbocharger system. Its robust construction and precise engineering help withstand the high temperatures and pressures inherent in the turbocharger’s operation, thereby contributing to the longevity of the engine system.

Conclusion

In summary, part 3531731 Turbine Housing is an integral component in the turbocharger system, playing a role in performance enhancement, system integration, and durability. Its careful design and engineering are important for the efficient and reliable operation of modern engine systems.

-

Bennett, S., & Norman, I. A. (2011). Heavy Duty Truck Systems, Fifth Edition. Delmar Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.