This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3531771 Turbine Housing is a component designed for use in turbocharger systems, specifically tailored to enhance engine performance in commercial trucks. This part is integral to the efficient operation of the turbocharger, which plays a significant role in improving the overall power and efficiency of the engine 1.

Basic Concepts of Turbine Housing

Turbine housings are fundamental components within turbocharger systems. Their primary function is to manage the flow of exhaust gases from the engine, directing them towards the turbine wheel. This process spins the turbine, which in turn drives the compressor wheel, increasing the intake air pressure and volume. The design and efficiency of the turbine housing directly influence the turbocharger’s performance, affecting how effectively it can increase engine power and efficiency 2.

Purpose of the 3531771 Turbine Housing

The Cummins 3531771 Turbine Housing is specifically engineered to optimize the airflow within the turbocharger system of a truck’s engine. By efficiently channeling exhaust gases, it enhances the turbine’s ability to spin faster, which directly contributes to improved airflow and engine performance. This part is designed to work in harmony with the engine’s requirements, ensuring that the turbocharger operates at peak efficiency.

Key Features

The 3531771 Turbine Housing boasts several design and material features that enhance its durability and performance. Constructed from high-quality materials, it is designed to withstand the high temperatures and pressures associated with exhaust gases. Its design includes features that promote efficient gas flow and reduce the likelihood of heat-related damage, ensuring long-term reliability and performance.

Benefits

Incorporating the Cummins 3531771 Turbine Housing into a truck’s engine system offers several advantages. It contributes to increased engine efficiency by optimizing turbocharger performance, leading to enhanced turbo response. Additionally, it can potentially improve fuel economy and increase power output, making it a valuable component for commercial truck applications 3.

Installation Considerations

When installing the 3531771 Turbine Housing, it is important to follow guidelines and best practices to ensure proper fit and function. Compatibility with various engine models should be verified, and the necessary tools and procedures should be used to facilitate a smooth installation process. Proper installation is key to achieving the desired performance enhancements and ensuring the longevity of the component.

Performance Impact

The introduction of the 3531771 Turbine Housing into a truck’s engine system can lead to noticeable changes in engine performance. Improvements in power, torque, and efficiency are possible, supported by empirical data that demonstrates the component’s effectiveness in enhancing turbocharger operation.

Troubleshooting and Maintenance

Common issues with turbine housings can include leaks, cracks, or inefficient gas flow, which may affect turbocharger performance. Regular inspection and maintenance practices can help identify and address these issues, ensuring the turbine housing continues to operate optimally and prolonging its lifespan.

Cummins Corporation Overview

Cummins Inc. is a well-established manufacturer in the commercial truck industry, known for its wide range of high-quality engine and powertrain solutions. The company’s reputation for reliability and innovation provides a solid foundation for the quality and performance of the 3531771 Turbine Housing, reflecting Cummins’ commitment to enhancing engine efficiency and performance in commercial applications.

Role of Part 3531771 Turbine Housing in Engine Systems

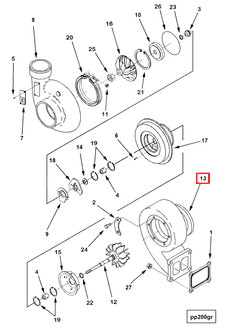

The 3531771 Turbine Housing is an integral component in the operation of turbocharger systems. It is designed to efficiently channel exhaust gases from the engine, which spin the turbine wheel inside the housing. This rotational energy is then transferred to the compressor wheel via a shaft, increasing the airflow into the engine and thereby boosting performance.

Integration with Turbocharger

When integrated into a turbocharger, the 3531771 Turbine Housing ensures that exhaust gases are directed with precision. The housing’s design allows for optimal gas flow, minimizing turbulence and maximizing the energy transferred to the turbine wheel. This efficient energy transfer is essential for the turbocharger to function effectively, enhancing engine performance by providing a denser air charge to the combustion chambers.

Contribution to Turbocharger Kit

In a turbocharger kit, the 3531771 Turbine Housing works in concert with other components such as the compressor housing, turbine wheel, and shaft. The housing’s role is to ensure that the exhaust gases are harnessed effectively, spinning the turbine wheel at high speeds. This, in turn, drives the compressor wheel, which compresses the intake air before it enters the engine. The result is improved engine efficiency and increased power output, making the turbocharger kit a valuable upgrade for performance-oriented applications.

Impact on Engine Performance

The effectiveness of the 3531771 Turbine Housing directly influences engine performance. By efficiently managing exhaust gas flow, it ensures that the turbocharger operates at peak efficiency. This leads to better throttle response, increased power across the RPM range, and improved overall engine performance. Engineers and mechanics must ensure that the turbine housing is correctly installed and maintained to achieve the desired performance gains from the turbocharger system.

Conclusion

The Cummins 3531771 Turbine Housing is a critical component for enhancing the performance and efficiency of turbocharger systems in commercial trucks. Its design and features contribute to improved engine performance, making it a valuable addition to any engine system. Proper installation and maintenance are essential to ensure optimal performance and longevity of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.