This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The 3533141 Turbine Housing, a component manufactured by Cummins, is designed for use in turbocharger systems of commercial trucks. It plays a significant role in enhancing engine performance and efficiency.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel. This process increases the amount of air entering the engine, thereby boosting power output and efficiency 1.

Role of the 3533141 Turbine Housing in Truck Operation

This Cummins part is integral to the operation of a truck’s engine. It facilitates the efficient conversion of exhaust gases into rotational energy for the turbine wheel. This conversion enhances engine efficiency by allowing for more air to be compressed and delivered into the combustion chamber, leading to improved power output. The housing’s design also contributes to the reduction of backpressure, which can otherwise hinder engine performance 2.

Key Features of the 3533141 Turbine Housing

The 3533141 Turbine Housing is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and resistance to the high temperatures and pressures within the turbocharger system. The housing features a precise internal geometry that optimizes the flow of exhaust gases, enhancing the efficiency of the turbocharger. Additionally, its construction ensures structural integrity under demanding operating conditions 3.

Benefits of Using the 3533141 Turbine Housing

Utilizing this part offers several advantages. It contributes to improved engine performance through efficient turbocharger operation. The housing’s durable construction ensures long-term reliability, reducing the need for frequent replacements. Moreover, its design helps in maintaining optimal engine efficiency, leading to better fuel economy and reduced emissions.

Installation Considerations

When installing the 3533141 Turbine Housing, it is important to ensure compatibility with the specific engine model and turbocharger system. Proper installation involves careful alignment and secure fastening to prevent leaks and ensure efficient operation. It is also advisable to follow manufacturer guidelines for installation to maintain warranty coverage and ensure optimal performance.

Maintenance and Troubleshooting

Routine maintenance of the 3533141 Turbine Housing includes inspecting for signs of wear, checking for leaks, and ensuring that all connections are secure. Common issues may include reduced performance due to deposits or damage to the housing. Regular cleaning and inspection can help identify and address these issues before they lead to significant performance drops.

Performance Enhancements

The 3533141 Turbine Housing can contribute to overall engine performance enhancements. By improving the efficiency of the turbocharger, it allows for increased airflow into the engine, which can lead to higher horsepower and torque outputs. This enhancement is particularly beneficial in commercial trucks, where engine performance directly impacts operational efficiency and productivity.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engine components. Their product range includes a variety of engine sizes and configurations, designed to meet the diverse needs of the commercial trucking sector.

Role of Part 3533141 Turbine Housing in Engine Systems

In the context of engine systems, the 3533141 Turbine Housing is an essential component that interfaces with several other parts to ensure optimal performance of the turbocharger system.

When integrated with an Aftermarket Turbocharger, the Turbine Housing plays a significant role in managing the exhaust flow. It directs the exhaust gases to spin the turbine wheel, which in turn drives the compressor wheel to increase air intake. This synergy enhances the overall efficiency and power output of the engine.

In a Pre-set Turbine Housing Kit, the Turbine Housing is pre-configured to match specific engine requirements. It ensures that the turbine wheel operates within its designed parameters, providing consistent boost levels and improving the responsiveness of the turbocharger.

The Turbine Housing is a core component of the Turbocharger system. It houses the turbine wheel and manages the flow of exhaust gases. Proper fitting and sealing of the Turbine Housing are vital for maintaining the pressure balance within the turbocharger, directly influencing its performance and durability.

Within a Turbocharger Kit, the Turbine Housing is often accompanied by other components such as the compressor housing, center housing, and various gaskets. Its role is to ensure that the exhaust gases are efficiently utilized to drive the turbine, which is essential for the kit’s overall functionality.

The integration of the Turbine Housing with the Wastegate T/Housing Sub-assembly is also noteworthy. The wastegate regulates the amount of exhaust gas that bypasses the turbine, controlling the boost pressure. The Turbine Housing must be precisely fitted to ensure that the wastegate can effectively manage the exhaust flow, preventing over-boosting and protecting the engine from potential damage.

Conclusion

The 3533141 Turbine Housing is a pivotal component in the turbocharger systems of commercial trucks. Its role in managing exhaust flow, enhancing turbocharger efficiency, and contributing to overall engine performance makes it an essential part of the engine system. Proper installation, maintenance, and understanding of its function are crucial for maximizing the benefits it offers.

SPECIFICATIONS

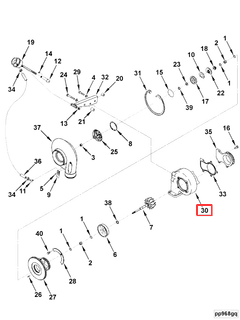

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.