This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

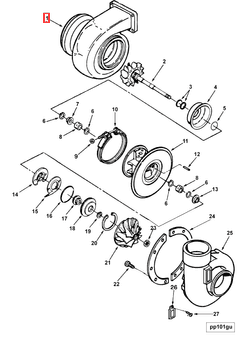

The Cummins 3533612 Turbine Housing is a component designed for use in turbocharger systems of heavy-duty trucks. Its purpose is to enhance the efficiency and performance of the engine by optimizing the turbocharger’s operation. Understanding the role of turbine housings in turbocharger systems is fundamental to appreciating the significance of this specific part.

Basic Concepts of Turbine Housings

A turbine housing is a component of a turbocharger system. It encases the turbine wheel, which is spun by the engine’s exhaust gases. The housing directs these gases to spin the turbine wheel, which in turn drives the compressor wheel via a shared shaft. This process increases the volume and pressure of air entering the engine, enhancing combustion efficiency and power output. The turbine housing’s design and construction are integral to the overall performance of the turbocharger, as they influence the flow of exhaust gases and the efficiency of energy transfer from the turbine to the compressor 1.

Purpose of the 3533612 Turbine Housing

The Cummins 3533612 Turbine Housing is specifically engineered to improve the operation of a truck’s engine. By optimizing the flow of exhaust gases, it enhances the efficiency of the turbocharger. This results in improved engine efficiency and performance, allowing the engine to produce more power with the same amount of fuel. The housing’s design contributes to better airflow dynamics, which is crucial for maintaining optimal engine performance under various operating conditions 2.

Key Features

The Cummins 3533612 Turbine Housing is characterized by its robust design and construction. It is made from high-quality materials that ensure durability and resistance to the high temperatures and pressures encountered in turbocharger systems. The housing’s structural integrity is enhanced by precision engineering, which ensures that it can withstand the rigors of heavy-duty truck operation. These features contribute to the housing’s performance and longevity, making it a reliable component in the turbocharger system 3.

Benefits

The advantages provided by the Cummins 3533612 Turbine Housing include improved airflow, enhanced engine response, and increased power output. These benefits contribute to overall truck performance by allowing the engine to operate more efficiently and with greater power. The housing’s design ensures that exhaust gases are directed optimally, maximizing the efficiency of the turbocharger and, by extension, the engine.

Installation Considerations

When installing the Cummins 3533612 Turbine Housing, it is important to follow guidelines and best practices to ensure optimal performance. Compatibility with various engine models should be verified to ensure proper fit and function. Proper installation is crucial for achieving the desired performance enhancements and avoiding potential issues down the line.

Troubleshooting and Maintenance

Common issues associated with turbine housings include leaks, cracks, and blockages. Regular inspection and maintenance can help identify these issues early and ensure the longevity and efficient operation of the Cummins 3533612 Turbine Housing. Recommended inspection and service intervals should be adhered to, and any signs of wear or damage should be addressed promptly.

Performance Enhancements

Upgrades or modifications to the turbine housing can affect engine performance. Aftermarket options may offer improvements in airflow, efficiency, and power output. However, it is important to consider the compatibility and quality of these upgrades to ensure they provide the desired benefits without compromising the integrity of the turbocharger system.

Cummins Corporation

Cummins Inc. is a leading manufacturer in the heavy-duty truck industry, known for its commitment to innovation and quality in automotive components. The company’s extensive product range and reputation for reliability make it a trusted choice for truck operators and manufacturers alike. Cummins’ dedication to advancing technology and improving performance is evident in its turbocharger components, including the 3533612 Turbine Housing.

Compatibility of Cummins Turbine Housing Part 3533612

The Cummins Turbine Housing part number 3533612 is designed to fit seamlessly within a range of high-performance engines, ensuring optimal functionality and reliability. This part is integral to the engine’s operation, providing a critical housing for the turbine.

QSK38 Engine

The QSK38 engine, known for its robust design and exceptional power output, incorporates the Turbine Housing part 3533612. This part is essential for maintaining the efficiency and durability of the engine, ensuring it can handle demanding applications.

CM850 Engine

Similarly, the CM850 engine benefits from the Turbine Housing part 3533612. This engine, recognized for its versatility and power, relies on this component to support its turbine, enhancing overall performance and longevity.

MCRS Engine

The MCRS engine also utilizes the Turbine Housing part 3533612. This part is crucial in this engine’s design, providing the necessary structure and support for the turbine, which is vital for the engine’s operational efficiency and reliability.

By integrating the Turbine Housing part 3533612, these engines achieve a balance of power, efficiency, and durability, making them suitable for a variety of demanding applications.

Role of Part 3533612 Turbine Housing in Engine Systems

The part 3533612 Turbine Housing is a component in the operation of various engine systems, particularly those utilizing turbochargers. Its primary function is to house the turbine wheel, which is driven by the exhaust gases expelled from the engine. This housing is integral to the turbocharger’s ability to compress intake air, thereby enhancing engine performance.

In the context of the Heat3B Turbocharger, the turbine housing plays a role in optimizing the flow of exhaust gases. The design of the housing affects the velocity and direction of these gases as they pass over the turbine wheel. Efficient gas flow is vital for maximizing the turbocharger’s efficiency and responsiveness.

When considering Performance Parts, the turbine housing is often modified or upgraded to improve the turbocharger’s performance. These modifications can include changes to the housing’s shape, size, or material, which can lead to better exhaust gas management and increased boost pressure.

In a standard Turbocharger setup, the turbine housing is connected to the exhaust manifold via a series of pipes and flanges. This connection ensures a sealed pathway for the exhaust gases to travel from the engine to the turbine wheel. The housing must be precisely engineered to withstand high temperatures and pressures while maintaining a leak-free seal.

Within a Turbocharger Kit, the turbine housing is typically one of the key components. It is designed to work in harmony with other parts such as the compressor housing, center housing, and bearing cartridge. The efficiency of the turbine housing directly influences the overall performance of the turbocharger kit, affecting factors such as spool-up time, boost pressure, and thermal efficiency.

Conclusion

In summary, the part 3533612 Turbine Housing is an element in the functionality of turbochargers and turbocharger kits. Its design and construction are vital for efficient exhaust gas flow, which in turn enhances the performance and reliability of the engine system.

-

Dixon, John. Modern Diesel Technology Preventive Maintenance and Inspection. Delmar Cengage Learning, 2010.

↩ -

Bari, Saiful. Diesel Engine Combustion, Emissions and Condition Monitoring. InTech, 2013.

↩ -

Miedema, S. A., and Z. Lu. The Dynamic Behavior of a Diesel Engine. Published by Drir S. A. Miedema, 2010.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.