This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Cummins 3534201 Turbine Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. It plays a role in optimizing the turbocharger’s efficiency, which in turn contributes to improved engine performance. Understanding its function and benefits can provide valuable insights for those involved in the maintenance and operation of heavy-duty trucks .

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbocharger systems. They are responsible for directing exhaust gases to spin the turbine wheel, which is connected to the compressor wheel via a shaft. This process increases the airflow into the engine, allowing for more fuel to be burned and thus generating more power. The design and efficiency of the turbine housing directly influence the turbocharger’s performance and, by extension, the engine’s overall efficiency .

Purpose and Function of the 3534201 Turbine Housing

The 3534201 Turbine Housing is specifically engineered to enhance the operation of a truck’s engine. It contributes to increased airflow by efficiently channeling exhaust gases, which results in improved turbo response. This enhanced response allows the engine to breathe more effectively, leading to better overall engine efficiency and performance. The housing’s design is tailored to maximize these benefits, ensuring that the turbocharger operates at peak efficiency .

Key Features

The 3534201 Turbine Housing boasts several distinctive features. Its design is optimized for efficient exhaust gas flow, which is crucial for turbo performance. The material composition is selected to withstand the high temperatures and pressures associated with turbocharger operation, ensuring durability and reliability. Additionally, any unique attributes, such as specific geometric designs or coatings, further distinguish it from other turbine housings, contributing to its performance advantages .

Benefits of Using the 3534201 Turbine Housing

Installing the 3534201 Turbine Housing offers several advantages. It enhances turbo performance by ensuring efficient exhaust gas flow, which translates to increased engine power. Improved airflow also contributes to better fuel efficiency, making it a valuable component for commercial truck operators looking to optimize their fleet’s performance. Furthermore, the robust design and material quality of the housing can contribute to the longevity of the turbocharger system, reducing the need for frequent replacements .

Installation Considerations

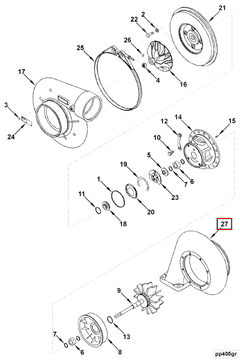

Proper installation of the 3534201 Turbine Housing is vital to ensure optimal performance and longevity. It is important to verify compatibility with specific engine models to ensure a proper fit and function. The installation process may require specific tools and equipment, and following manufacturer guidelines can help prevent common installation errors. Taking precautions such as inspecting gaskets and seals, and ensuring all connections are secure, can contribute to a successful installation .

Troubleshooting and Maintenance

Common issues with turbine housings may include leaks, cracks, or inefficient exhaust gas flow. Diagnostic procedures can help identify these problems, allowing for timely repairs or replacements. Regular maintenance practices, such as inspecting for damage, cleaning, and ensuring all connections are tight, can help prolong the lifespan and optimal performance of the turbine housing. Adhering to manufacturer recommendations for maintenance intervals can also contribute to the component’s reliability .

Cummins Overview

Cummins Inc. is a well-established company in the automotive industry, known for its commitment to producing high-quality turbocharger components. With a rich history and a strong reputation, Cummins has consistently delivered reliable and efficient turbocharger solutions for commercial trucks. Their dedication to innovation and quality ensures that components like the 3534201 Turbine Housing meet the demanding requirements of heavy-duty applications .

Role of 3534201 Turbine Housing in Engine Systems

The 3534201 Turbine Housing is an integral component in the operation of various engine systems, particularly when paired with aftermarket turbochargers and performance parts. Its primary function is to house the turbine wheel, which is driven by the exhaust gases expelled from the engine. This housing is designed to optimize the flow of these gases, enhancing the efficiency of the turbocharger.

When integrated with an aftermarket turbocharger, the Turbine Housing plays a significant role in improving the engine’s power output. The design of the housing affects the turbocharger’s response and efficiency, making it a key factor in the overall performance of the engine. In systems utilizing the HX80 turbocharger, the Turbine Housing is essential for managing the high flow rates and pressures associated with this type of turbocharger.

In conjunction with the Heat Exchanger 80 (HX80) turbocharger, the Turbine Housing aids in maintaining optimal temperatures for the turbocharger components. This is particularly important in high-performance engines where thermal management is key to sustaining power and reliability.

The Turbine Housing also interacts with the engine piston and injector systems. By enhancing the turbocharger’s efficiency, it allows for better air-fuel mixture management, which is critical for the injector’s performance. This, in turn, leads to more efficient combustion and improved engine performance.

Furthermore, in systems where an oil connection is present, the Turbine Housing ensures that the turbocharger receives adequate lubrication. This is vital for the longevity and smooth operation of the turbocharger, especially under high-stress conditions .

Conclusion

The 3534201 Turbine Housing is a pivotal component in various engine systems, particularly when enhancing the performance of turbochargers and managing the intricate balance of air, fuel, and exhaust in high-performance engines. Its design and material are carefully chosen to meet the stringent requirements of each engine model, ensuring that they operate at peak efficiency .

: Denton, T., & Pells, H. (2022). *Automotive Technician Training, Second Edition*. Routledge.

: Hilgers, M., & Achenbach, W. (2021). *Vocational Vehicles and Applications*. Springer Vieweg.

: Ribbens, W. B. (2003). *Understanding Automotive Electronics*. Elsevier Science.

: ElGindy, M., & ElSayegh, Z. (2023). *Road and Off-Road Vehicle Dynamics*. Springer Nature.SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.