This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

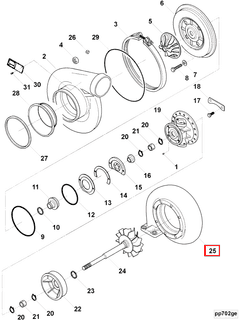

The 3539917 Turbine Housing by Cummins is a component designed for use in turbocharger systems, specifically tailored for heavy-duty truck applications. This part is integral to the turbocharger’s operation, facilitating efficient engine performance by managing exhaust gases. Its application in heavy-duty trucks underscores the importance of robust and reliable components in demanding environments.

Basic Concepts of Turbine Housing

Turbine housings are fundamental components in turbocharger systems. They encase the turbine wheel, which is spun by exhaust gases exiting the engine. This spinning action drives the compressor wheel, which compresses incoming air before it enters the engine’s combustion chambers. The design and efficiency of the turbine housing directly influence the turbocharger’s performance, impacting engine power, fuel efficiency, and overall vehicle performance 1.

Purpose of the 3539917 Turbine Housing

This Cummins part is engineered to optimize the flow of exhaust gases around the turbine wheel. By efficiently channeling these gases, it enhances the turbine’s rotational speed, which in turn increases the compressor’s efficiency. This results in a more effective air-fuel mixture being delivered to the engine, contributing to improved performance and efficiency.

Key Features

The 3539917 boasts several design and manufacturing features that enhance its performance and durability. Constructed from high-quality materials, it is designed to withstand the high temperatures and pressures associated with heavy-duty truck engines. Its precise engineering ensures optimal gas flow, while robust construction techniques contribute to its longevity under demanding conditions 2.

Benefits

Incorporating this part into a truck’s turbocharger system offers several advantages. It contributes to improved engine efficiency by ensuring that the turbocharger operates at peak performance. This results in increased power output, allowing the vehicle to handle heavy loads more effectively. Additionally, its durable construction ensures reliability under the high-stress conditions typical in heavy-duty truck applications.

Installation Process

Proper installation of the 3539917 is crucial for ensuring optimal performance and longevity. The process involves securing the housing to the engine’s exhaust system, ensuring a tight seal to prevent leaks. Careful alignment with the turbocharger’s turbine wheel is necessary to maintain efficient gas flow. Following manufacturer guidelines during installation helps achieve the best results.

Common Issues and Troubleshooting

Turbine housings, including the 3539917, may encounter issues such as leaks, cracks, or efficiency losses over time. Regular inspections can help identify these problems early. Troubleshooting may involve checking for proper installation, ensuring seals are intact, and assessing the condition of the housing for signs of wear or damage. Addressing these issues promptly can prevent more significant problems and maintain turbocharger efficiency.

Maintenance Tips

Maintaining the 3539917 is key to ensuring long-term reliability and performance. Regular inspection routines should be established to check for signs of wear, damage, or leaks. Cleaning the housing to remove any buildup that could impede gas flow is also recommended. Adhering to recommended service intervals for inspection and maintenance helps preserve the turbocharger’s efficiency and durability.

Performance Enhancements

For those looking to further improve turbocharger performance, several upgrades and modifications can be considered for the 3539917. Aftermarket options may offer enhanced designs for better gas flow or increased durability. Tuning considerations, such as adjusting the turbocharger’s boost levels, can also contribute to improved performance, provided they are done within the component’s operational limits.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive and heavy-duty truck industry, known for its wide range of high-quality products. With a rich history of innovation and excellence, Cummins has established a reputation for reliability and performance. This background underscores the quality and dependability of the 3539917, reflecting Cummins’ commitment to excellence in turbocharger technology.

Compatibility

The 3539917 is designed to fit seamlessly within several engine models, ensuring optimal performance and reliability. This part is integral to the engine’s operation, providing a critical housing for the turbine.

QSV91G and QSW/QSV82 Engines

For the QSV91G engine, the Turbine Housing part 3539917 is specifically engineered to match the engine’s design, ensuring precise fitment and function. This housing is crucial for maintaining the integrity of the turbine system, which is vital for the engine’s overall efficiency and power output.

Similarly, the QSW/QSV82 engines also benefit from the Turbine Housing part 3539917. This part is crafted to align perfectly with the specifications of the QSW/QSV82 engines, ensuring that the turbine operates within its designed parameters. The precision of this fitment is essential for the longevity and performance of the engine.

Installation and Integration

When installing the Turbine Housing part 3539917, it is imperative to follow the manufacturer’s guidelines to ensure proper integration with the engine. This part must be securely fastened and aligned correctly to prevent any operational issues. Proper installation not only enhances the engine’s performance but also extends its service life.

Compatibility Considerations

While the Turbine Housing part 3539917 is compatible with the QSV91G and QSW/QSV82 engines, it is crucial to verify the part number and specifications before installation. Ensuring that the correct part is used for the specific engine model is essential for maintaining the engine’s efficiency and reliability.

Understanding the Role of Part 3539917 Turbine Housing in Turbocharger Systems

When integrating Part 3539917 Turbine Housing into various turbocharger systems, it is essential to grasp its function within the assembly. This component is a fundamental part of the turbocharger’s exhaust side, where it encases the turbine wheel.

In an Aftermarket Turbocharger, the turbine housing is often modified to improve performance. The housing directs exhaust gases onto the turbine wheel, spinning it at high speeds. This, in turn, drives the compressor wheel, which compresses intake air before it enters the engine. The efficiency of this process is significantly influenced by the design and condition of the turbine housing.

Within a Turbocharger Assembly, the turbine housing works in concert with other components such as the compressor housing, center housing, and shaft. The turbine housing must be precisely matched to these parts to ensure optimal airflow and pressure ratios. Any discrepancies can lead to reduced efficiency or even failure of the turbocharger.

In a Turbocharger Kit, which typically includes the turbocharger, mounting brackets, and necessary gaskets, the turbine housing plays a pivotal role in the overall performance. It is often one of the first components to be inspected for wear or damage, as its condition directly affects the turbocharger’s ability to generate boost.

For a Turbocharger, whether it is a stock unit or a high-performance variant, the turbine housing is integral to maintaining the correct exhaust gas flow. Its design can vary significantly depending on the application, with some housings featuring variable geometry to adapt to different engine loads and RPM ranges.

Conclusion

In summary, Part 3539917 Turbine Housing is a key component in ensuring the turbocharger operates efficiently. Its interaction with exhaust gases and the turbine wheel is essential for generating the necessary boost to enhance engine performance. Proper installation, maintenance, and understanding of its role within the turbocharger system are crucial for maximizing its benefits and ensuring the longevity and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.