This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

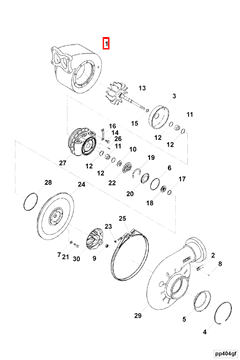

The Cummins 3590561 Turbine Housing is a component designed for use in turbocharger systems of heavy-duty trucks. Its purpose is to house the turbine wheel, which is a part of the turbocharger’s operation. The Turbine Housing plays a role in the efficiency and performance of the engine by managing the flow of exhaust gases that drive the turbocharger.

Basic Concepts of Turbine Housings

A turbine housing is a part of the turbocharger that encases the turbine wheel. Its function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel to increase the airflow into the engine. The efficiency of this process directly impacts engine performance. The turbine housing works in conjunction with other turbocharger components, such as the compressor housing and the center housing, to optimize the flow of gases and air 1.

Purpose of the 3590561 Turbine Housing

The 3590561 Turbine Housing is specifically engineered to enhance the operation of a truck’s engine. It aids in improving engine efficiency and power output by effectively channeling exhaust gases to the turbine wheel. This results in a more responsive turbocharger, which can lead to better acceleration and overall engine performance 2.

Key Features

The 3590561 Turbine Housing is constructed with a focus on performance and durability. It is made from high-quality materials that can withstand the high temperatures and pressures of exhaust gases. The design includes precise engineering to ensure optimal gas flow and efficiency. Unique characteristics such as reinforced areas and heat-resistant coatings may be present to enhance its performance and longevity.

Benefits

Using the 3590561 Turbine Housing can lead to improved engine performance, increased fuel efficiency, and enhanced durability. These benefits contribute to the overall operation of the truck by ensuring that the engine runs more efficiently and with greater power, which can be particularly advantageous in heavy-duty applications 3.

Installation Process

Installing the 3590561 Turbine Housing requires careful attention to detail to ensure proper fitting and function. The process involves securing the housing to the engine and turbocharger, ensuring all connections are tight and secure. It is important to follow manufacturer guidelines and use the appropriate tools to avoid damage to the component or the engine.

Common Issues and Troubleshooting

Common issues with the 3590561 Turbine Housing may include leaks, cracks, or a decline in performance. These issues can often be identified through regular inspection and performance monitoring. Troubleshooting may involve checking for proper installation, inspecting for damage, and ensuring that all connections are secure. Recommended solutions can range from re-tightening connections to replacing damaged components.

Maintenance Tips

To prolong the lifespan of the 3590561 Turbine Housing, regular inspection and cleaning are recommended. This includes checking for signs of wear or damage and ensuring that all connections remain secure. It is also important to follow the manufacturer’s guidelines for maintenance intervals and to consider replacement if significant wear or damage is detected.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer with a broad range of products in the heavy-duty truck industry. The company is known for its commitment to quality and innovation in engine component manufacturing. Cummins’ reputation is built on a history of producing reliable and high-performing parts, which is reflected in their turbine housings and other engine components.

Turbine Housing Compatibility with Cummins Engines

The Turbine Housing part number 3590561, manufactured by Cummins, is a component that fits seamlessly with several of their engine models. This part is integral to the engine’s operation, ensuring efficient airflow and performance. Here’s a detailed look at its compatibility across various Cummins engines:

K50 Series

The K50 series engines, which include the K50, QSK38 CM850 MCRS, and QSK50 CM2150 K107, all feature the Turbine Housing part number 3590561. This part is designed to integrate perfectly with the K50’s architecture, providing a robust and reliable housing for the turbine.

QSK Series

The QSK series engines, such as the QSK45 CM500, QSK50 CM2150 MCRS, and QSK78 CM500, also utilize the Turbine Housing part number 3590561. This part is engineered to fit these engines, ensuring optimal performance and durability. The QSK series engines benefit from this housing’s precision engineering, which enhances the overall efficiency of the turbine.

QSK60G

The QSK60G engine is another model that is compatible with the Turbine Housing part number 3590561. This part is specifically designed to fit the QSK60G, ensuring that the turbine operates at peak efficiency. The QSK60G’s design benefits from the precise fit and high-quality construction of this turbine housing.

Grouping of Compatible Engines

When considering the compatibility of the Turbine Housing part number 3590561, it is evident that several engines share this component. The K50 series and QSK series engines, in particular, benefit from this part’s design, ensuring that the turbine operates efficiently and reliably. The QSK60G, while a distinct model, also utilizes this housing, highlighting its versatility and importance across different engine types.

By understanding the compatibility of the Turbine Housing part number 3590561 with these engines, technicians and engineers can ensure that the correct part is used for maintenance and repairs, maintaining the engine’s performance and longevity.

Understanding the Integration of Part 3590561 Turbine Housing in Engine Systems

When integrating the part 3590561 Turbine Housing into various engine systems, it is essential to understand its interaction with other components to ensure optimal performance and efficiency.

Interaction with Aftercooler Core

The Turbine Housing, when paired with an Aftercooler Core, plays a role in managing the temperature of the compressed air. The Aftercooler Core cools the air after it has been compressed by the Turbocharger, and the Turbine Housing aids in this process by efficiently channeling exhaust gases to drive the turbine wheel. This synergy ensures that the air entering the engine is at an optimal temperature, enhancing combustion efficiency and power output.

Role in Aftermarket Turbocharger Systems

In aftermarket Turbocharger setups, the Turbine Housing is a component that influences the overall performance of the Turbocharger. It is responsible for housing the turbine wheel, which is driven by the exhaust gases. The design and material of the Turbine Housing affect the Turbocharger’s response time and efficiency. When upgrading to an aftermarket Turbocharger, ensuring that the Turbine Housing is compatible and efficiently designed is vital for achieving the desired performance gains.

Integration in Turbocharger Kits

Turbocharger Kits often include a Turbine Housing as part of the comprehensive package designed to enhance engine performance. The Turbine Housing in these kits is engineered to work seamlessly with the other components, such as the compressor housing and the turbocharger itself. Proper integration ensures that the Turbocharger Kit delivers consistent boost pressure and improved airflow, leading to increased power and efficiency.

Compatibility with TA Luft Turbocharger

For TA Luft Turbocharger applications, the Turbine Housing must be precisely engineered to meet specific emissions and performance standards. The Turbine Housing works in conjunction with the TA Luft Turbocharger to ensure that the engine complies with environmental regulations while maintaining high performance. This integration is particularly important in regions with stringent emissions controls.

Function in Turbocharger Repair Kits

In Turbocharger Repair Kits, the Turbine Housing may be included to replace a damaged or worn-out component. Its role is to restore the Turbocharger’s functionality by providing a durable and efficient housing for the turbine wheel. Proper installation of the Turbine Housing in a repair kit is essential to ensure that the Turbocharger operates within its designed parameters, thereby extending the engine’s lifespan and performance.

Overall System Efficiency

Across all these applications, the Turbine Housing’s role is to facilitate the efficient transfer of energy from exhaust gases to the turbine wheel. This energy transfer is fundamental to the operation of the Turbocharger, influencing boost pressure, response time, and overall engine efficiency. Ensuring that the Turbine Housing is well-integrated with the other components in the engine system is key to achieving optimal performance and reliability.

Conclusion

The 3590561 Turbine Housing is a critical component in the turbocharger systems of heavy-duty trucks, designed to enhance engine efficiency and performance. Its precise engineering and high-quality construction ensure optimal gas flow and efficiency, contributing to improved engine performance, increased fuel efficiency, and enhanced durability. Proper installation, regular maintenance, and understanding its compatibility with various engine models are essential for maximizing the benefits of this Cummins part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.